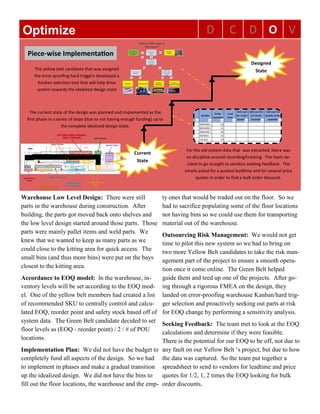

The company implemented a new inventory management system with a centralized warehouse and manual processes. A Green Belt designed the new system which included conducting interviews and process mapping to understand current issues, measuring parts to estimate warehouse capacity needs, and conceptualizing the new system with replenishment loops and kanbans. The final design included value stream mapping, layout of the warehouse with racking and material handling equipment, and kanban designs. The system was implemented in phases due to budget constraints but set up the foundation for an upcoming ERP system transition.