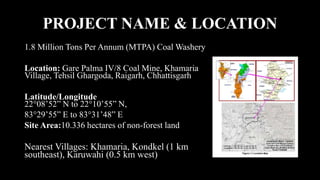

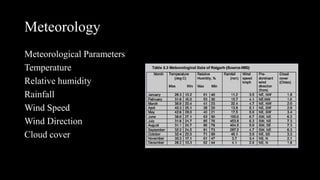

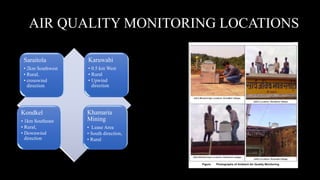

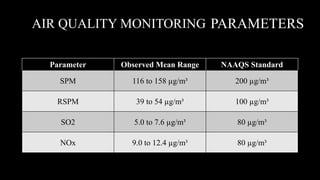

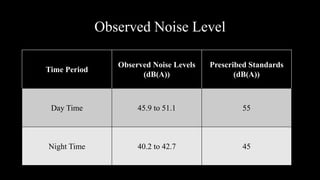

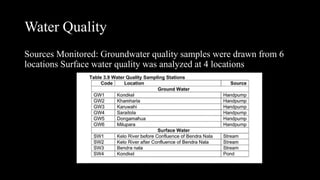

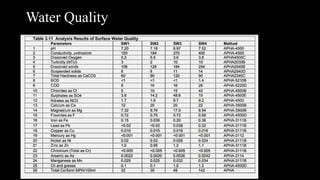

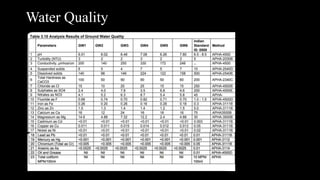

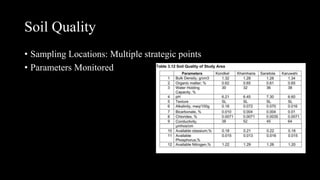

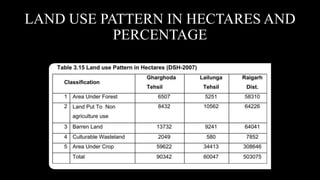

The document provides an environmental impact assessment for a proposed 1.8 mtpa coal washery by Jayaswal Neco Industries Limited in Chhattisgarh, detailing project specifics, production processes, and environmental management plans. The assessment highlights various monitoring parameters, mitigation measures, and a commitment to environmental compliance through an established environmental management cell. Additionally, the document outlines the procedures for air quality, water quality, noise levels, and waste management to minimize the project's environmental footprint.