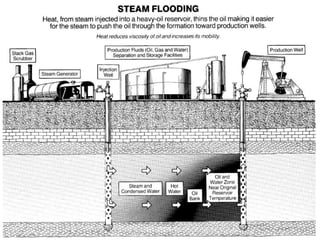

(1) Steam injection adalah salah satu metode eksploitasi minyak berat yang paling umum, yang bertujuan mengurangi viskositas minyak di reservoir melalui pemanasan.

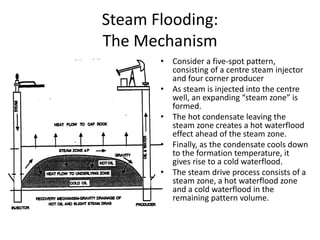

(2) Dua metode utama steam injection adalah Cyclic Steam Stimulation dan Steam Flooding.

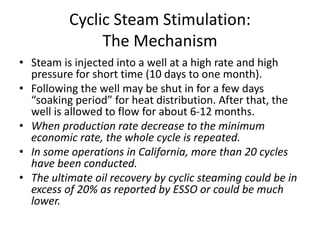

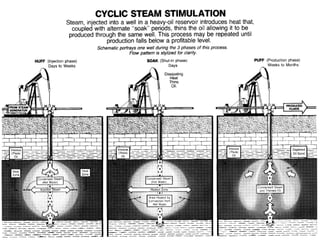

(3) Cyclic Steam Stimulation terdiri dari tahapan injeksi uap, penggenangan, dan produksi yang diulang berkali-kali.