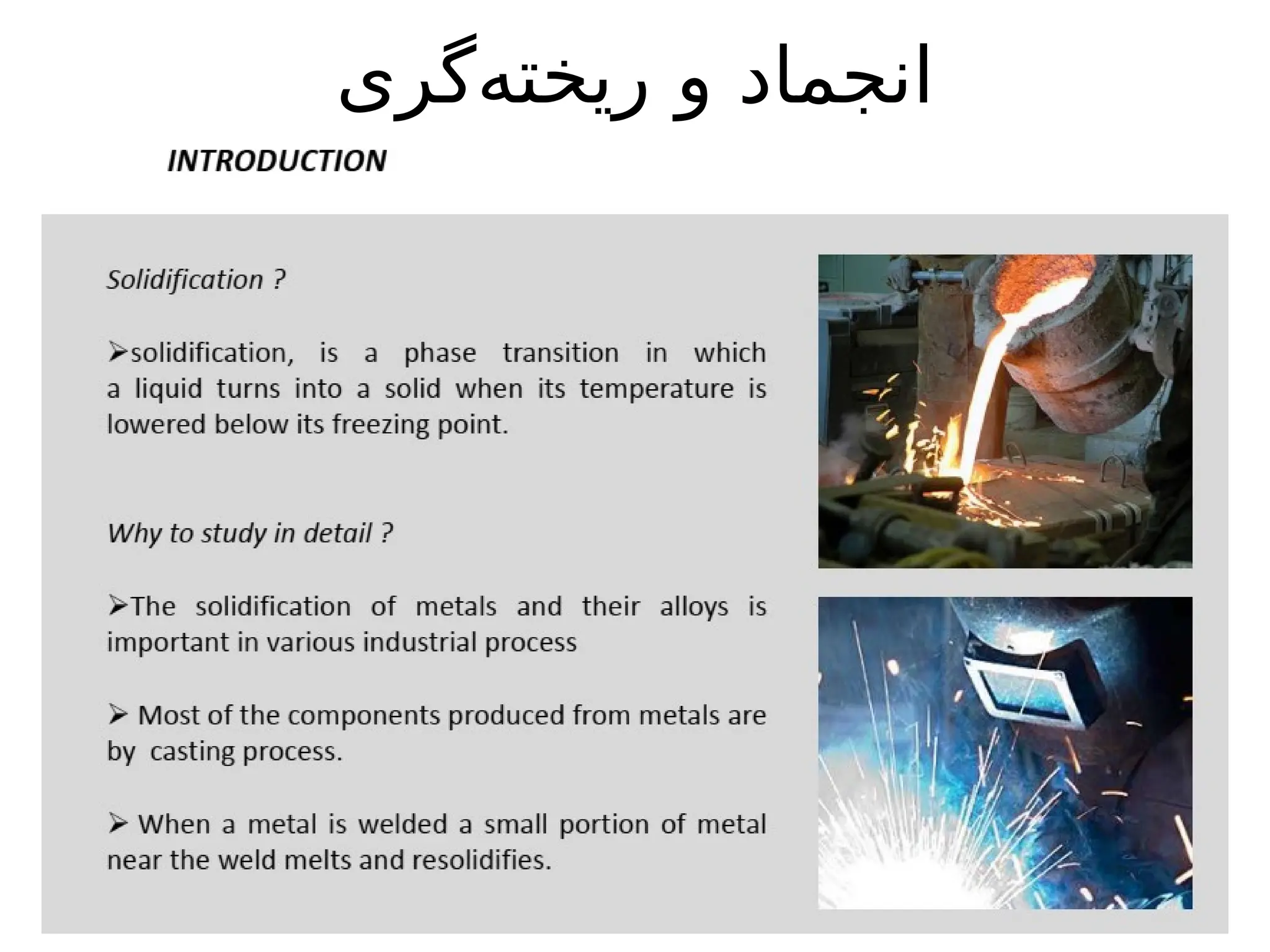

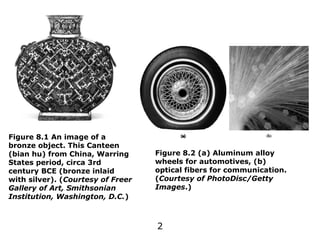

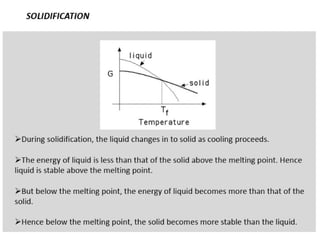

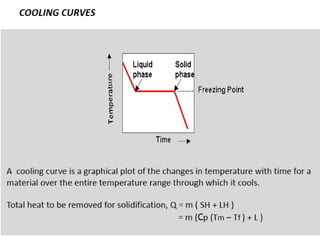

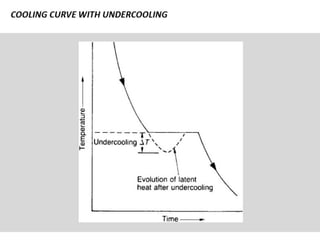

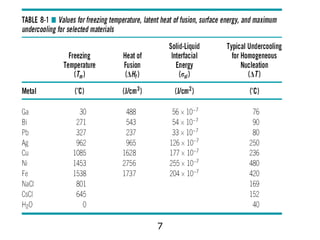

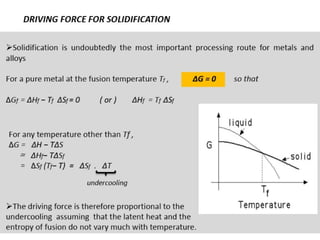

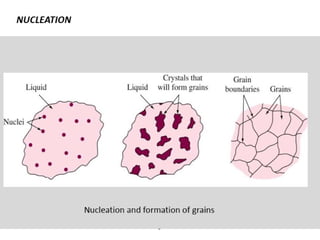

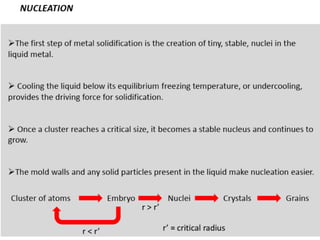

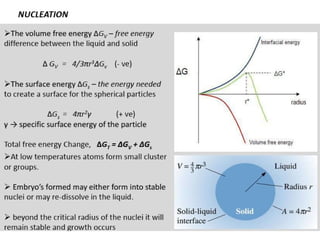

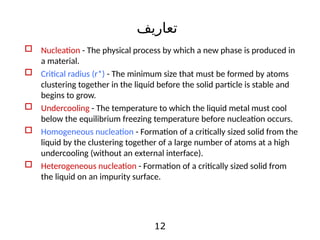

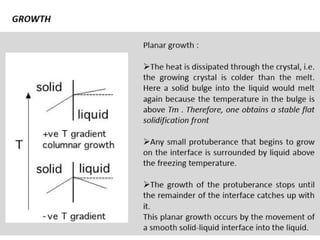

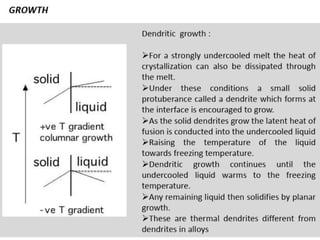

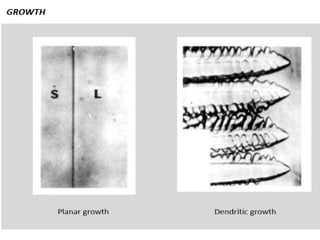

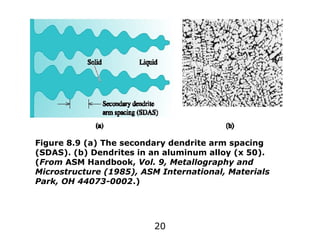

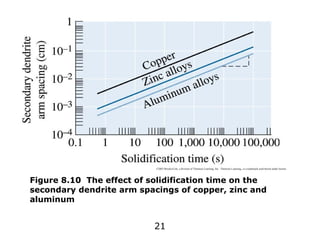

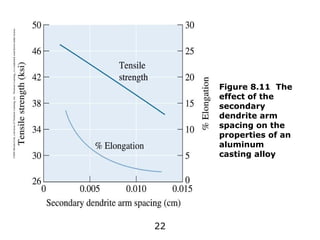

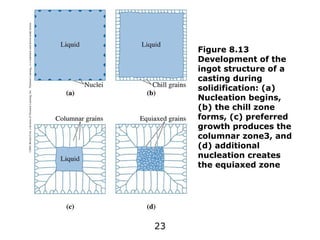

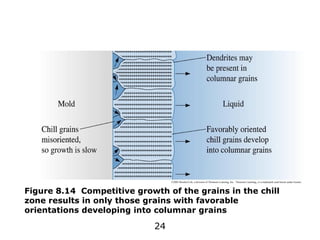

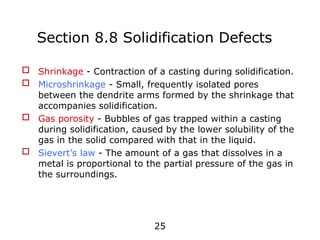

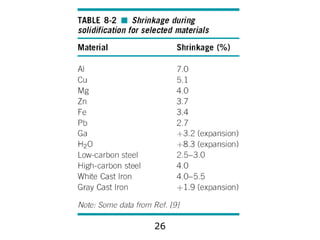

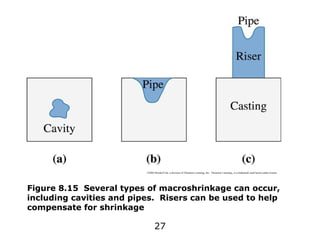

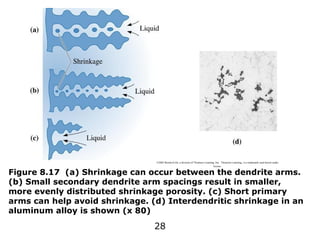

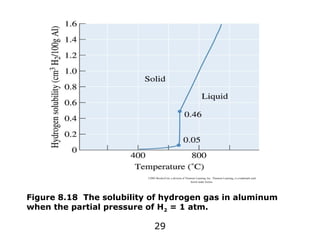

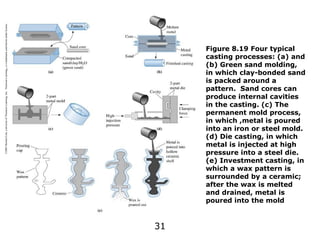

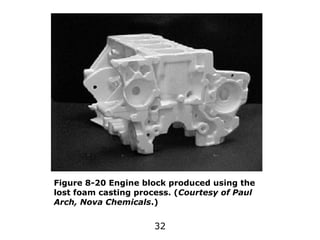

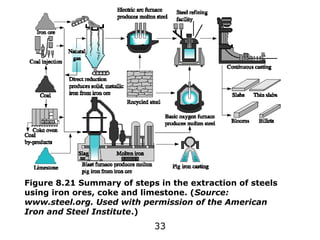

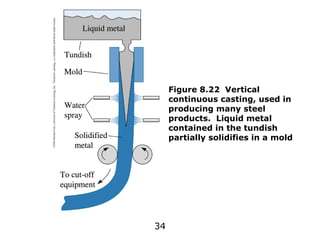

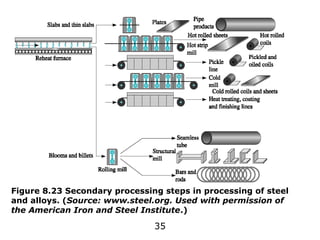

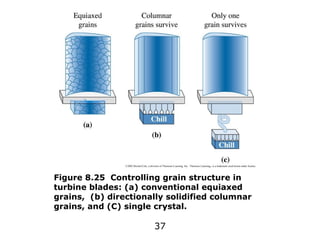

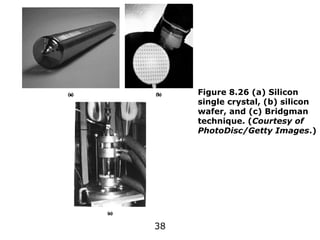

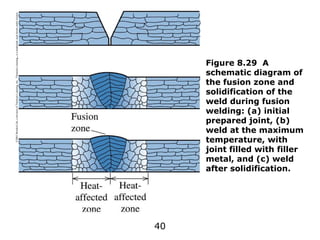

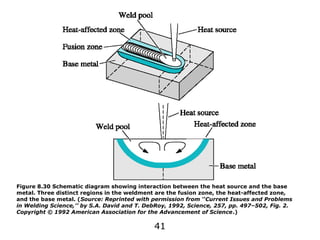

The document discusses various processes and phenomena related to the solidification of metals and alloys, including nucleation, undercooling, and solidification defects. It describes different casting methods such as sand casting, investment casting, and die casting, along with their applications. Additionally, it covers techniques for controlling microstructures in solidified materials and the methods of joining metallic materials through processes like brazing and fusion welding.