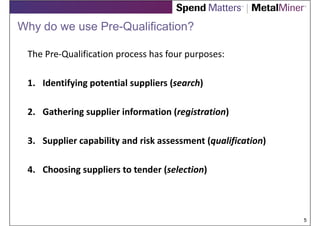

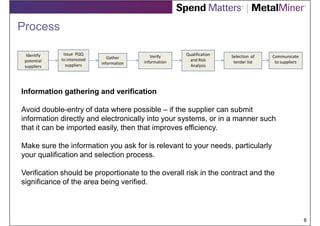

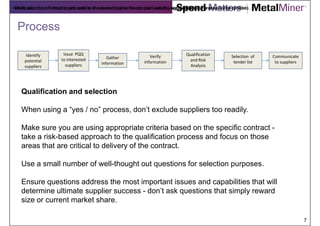

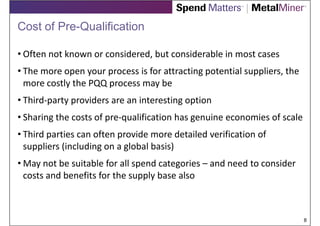

The document discusses the importance of the pre-qualification process in procurement, highlighting its four main purposes: identifying potential suppliers, gathering supplier information, assessing supplier capability and risk, and selecting suppliers to tender. It emphasizes the significance of avoiding unsuitable suppliers, ensuring the process is efficient and proportionate to risk, and considering the costs involved. The role of third-party providers in enhancing the pre-qualification process is also noted, along with the importance of making the process fair and transparent for suppliers.