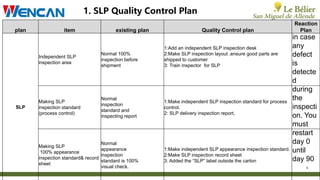

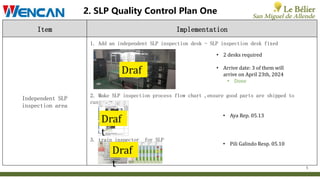

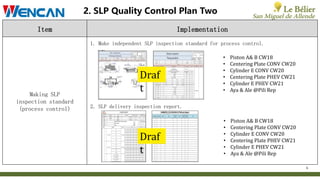

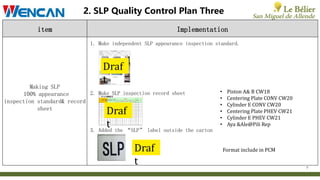

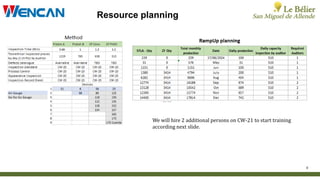

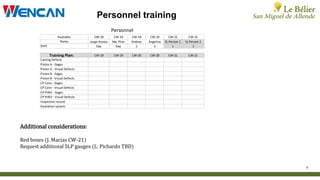

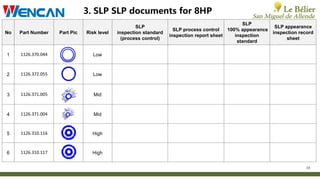

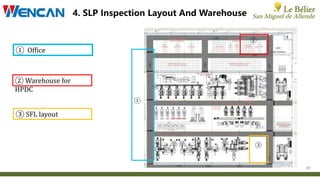

The document outlines a quality control plan for the 8hp SLP process, detailing responsibilities, key dates, and necessary inspections for defect detection. It includes implementation steps for establishing independent inspection areas and standardizing inspection processes to ensure high quality before shipment. Additionally, it mentions resource planning for personnel training and equipment required for effective execution of the plan.