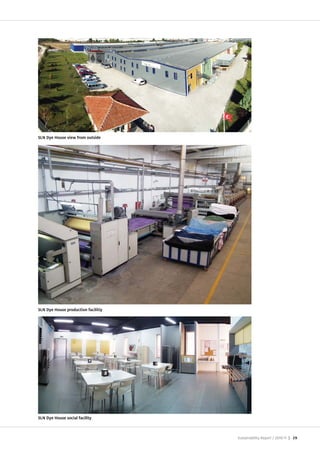

This sustainability report from SLN provides an overview of the company's operations and sustainability performance from 2010-2011. SLN is a leading Turkish textile and apparel company with 350,000 unit/month apparel production capacity and 15 tonnes/day dye production capacity. The report discusses SLN's approach to sustainability, stakeholder engagement, economic and environmental impacts, and social initiatives. Key highlights include investing in a new dye house to improve quality, speed and pricing, implementing lean production programs, and measuring water and carbon footprints to track environmental impacts.