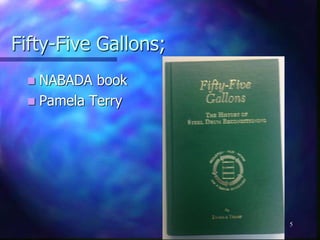

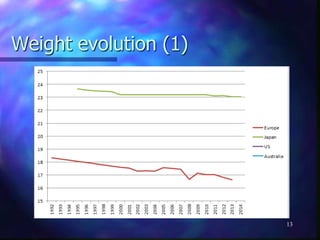

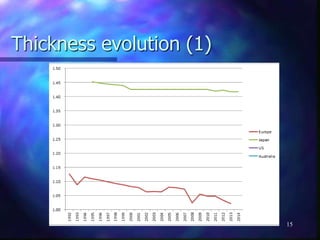

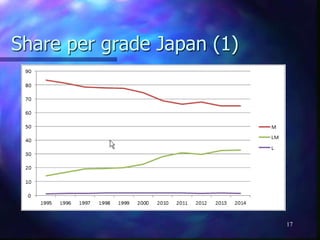

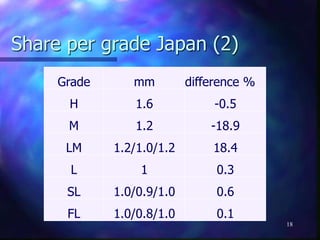

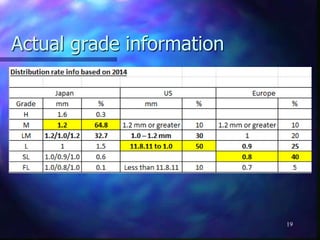

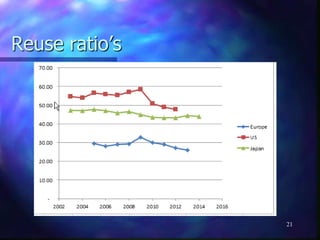

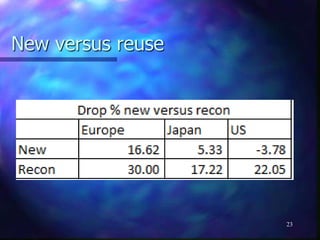

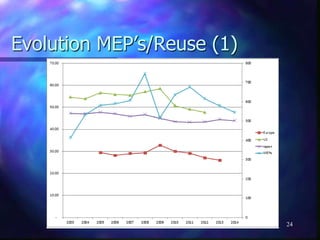

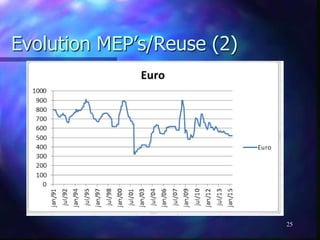

This document provides a historic overview of steel drum thicknesses and the evolution of the steel drum industry. It discusses the development of steel drums from glass and wooden barrels, the UN recommendations for transporting dangerous goods which do not specify a minimum thickness, and how thicknesses have decreased over time in various regions. For example, thicknesses in Europe have decreased from 1.3mm to 1.0mm on average. The document also examines reuse rates which have declined slightly in recent years in the US, Europe, and Japan. Overall, it traces the history and regulations of steel drums while analyzing changes in thicknesses, weights, and reuse.