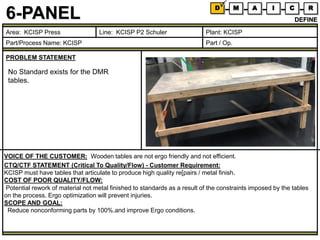

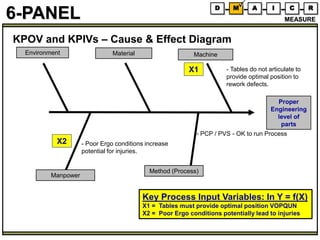

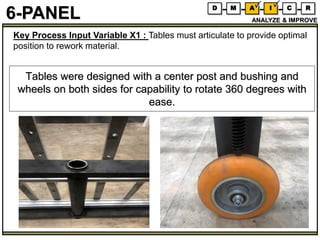

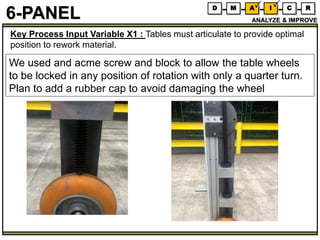

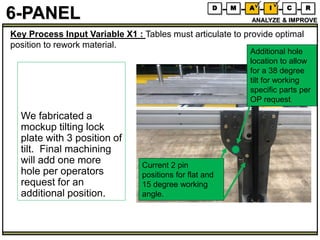

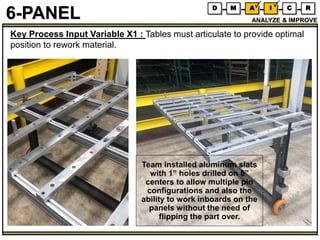

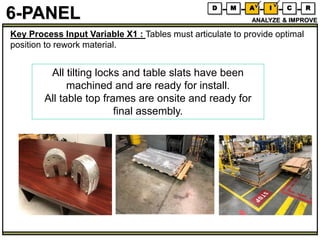

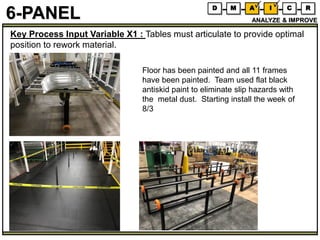

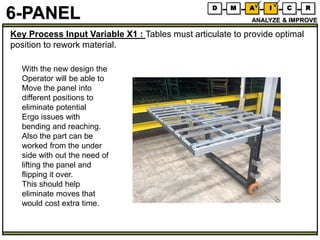

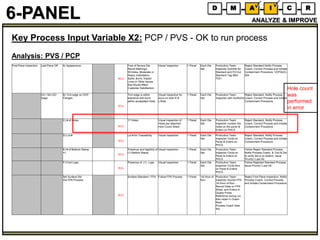

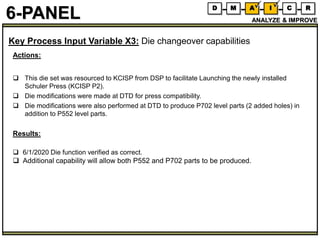

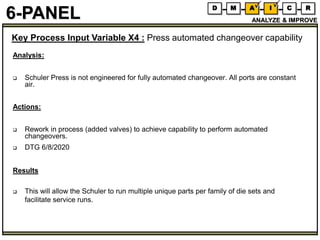

This document describes a problem solving project to improve the DMR tilt tables used in the Kansas City Integrated Stamping Plant. The project team designed and built new tilt tables that allow 360 degree rotation and multiple tilt positions for optimal part positioning. This will improve ergonomics and reduce nonconforming parts. The document also details analyses and improvements made to inspection processes, die changeover capabilities, press automation, and adding error proofing at the die shop to control quality.