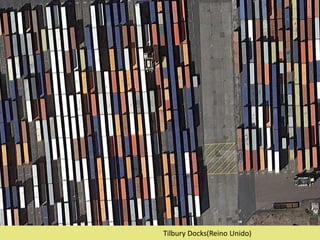

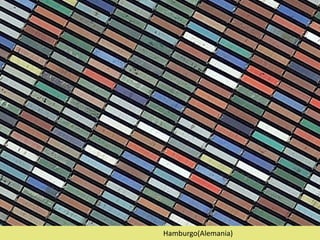

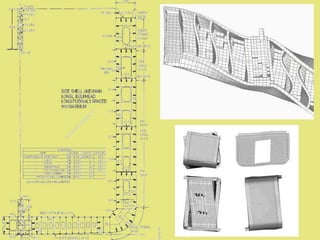

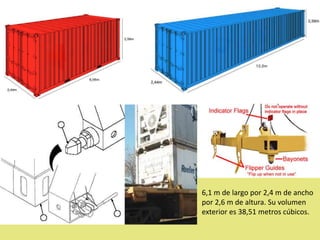

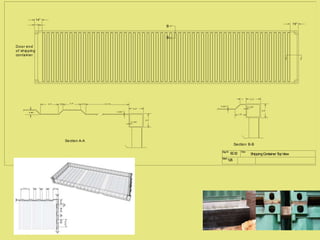

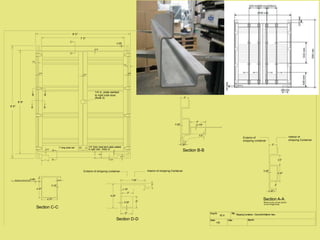

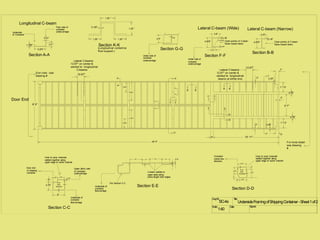

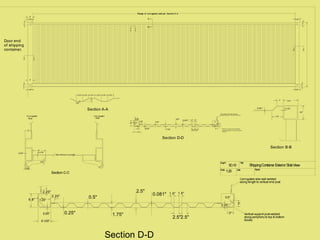

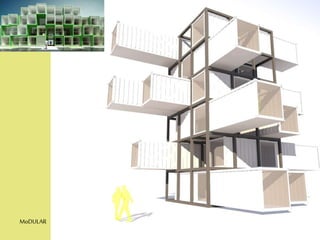

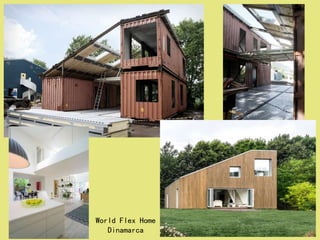

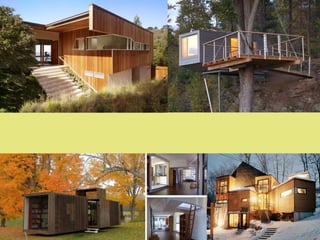

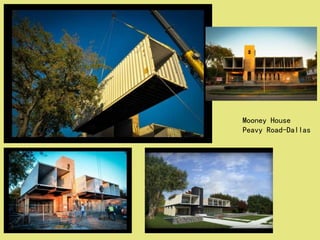

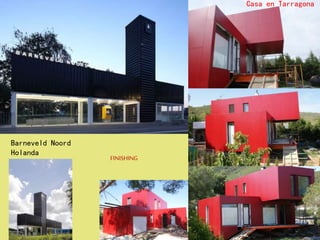

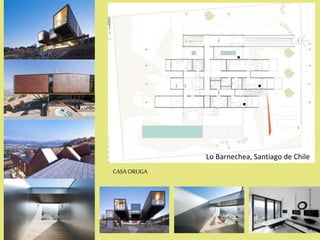

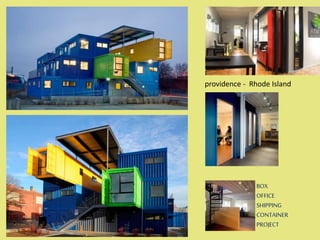

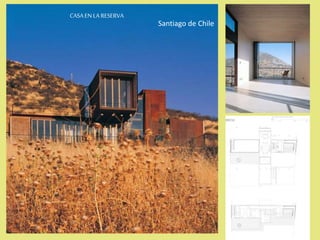

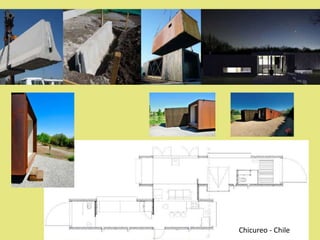

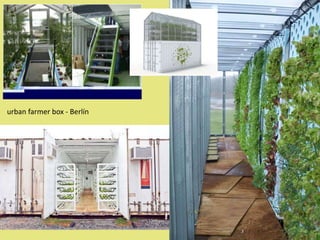

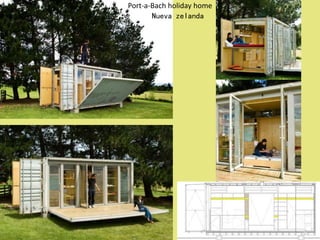

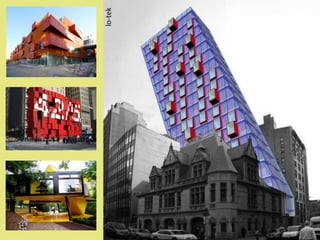

This document contains diagrams and drawings of shipping container designs and structural elements. It includes exterior and interior views of standard 6.1m shipping containers, showing dimensions of walls, doors, and framing supports. Additional drawings showcase container housing project examples from around the world, modifying and combining containers for residential, educational, and commercial uses. Labels include places like Denmark, Dallas, Tarragona, New Zealand, London, Berlin, Indonesia, Chile, Rhode Island, Brighton, Argentina, and Cantabria.