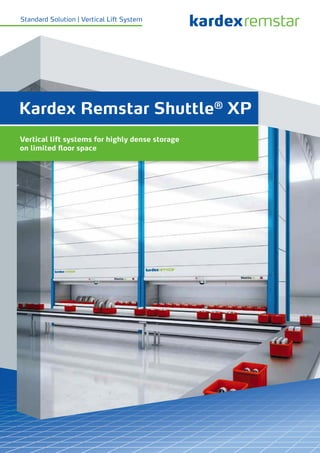

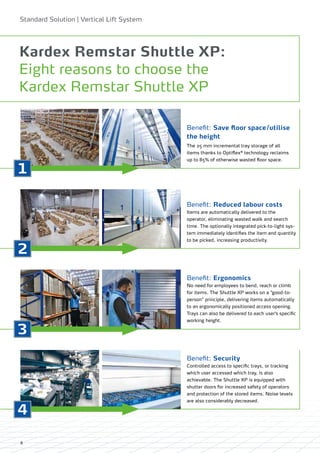

The Kardex Remstar Shuttle XP is a modular vertical lift system designed for efficient storage and retrieval in various applications, maximizing storage density while minimizing floor space usage. It features automated tray delivery, the ability to adapt height and access openings, and integrates with warehouse management systems for precise inventory control. Key benefits include improved ergonomics, security, flexibility, and reduced labor costs due to automated item retrieval.