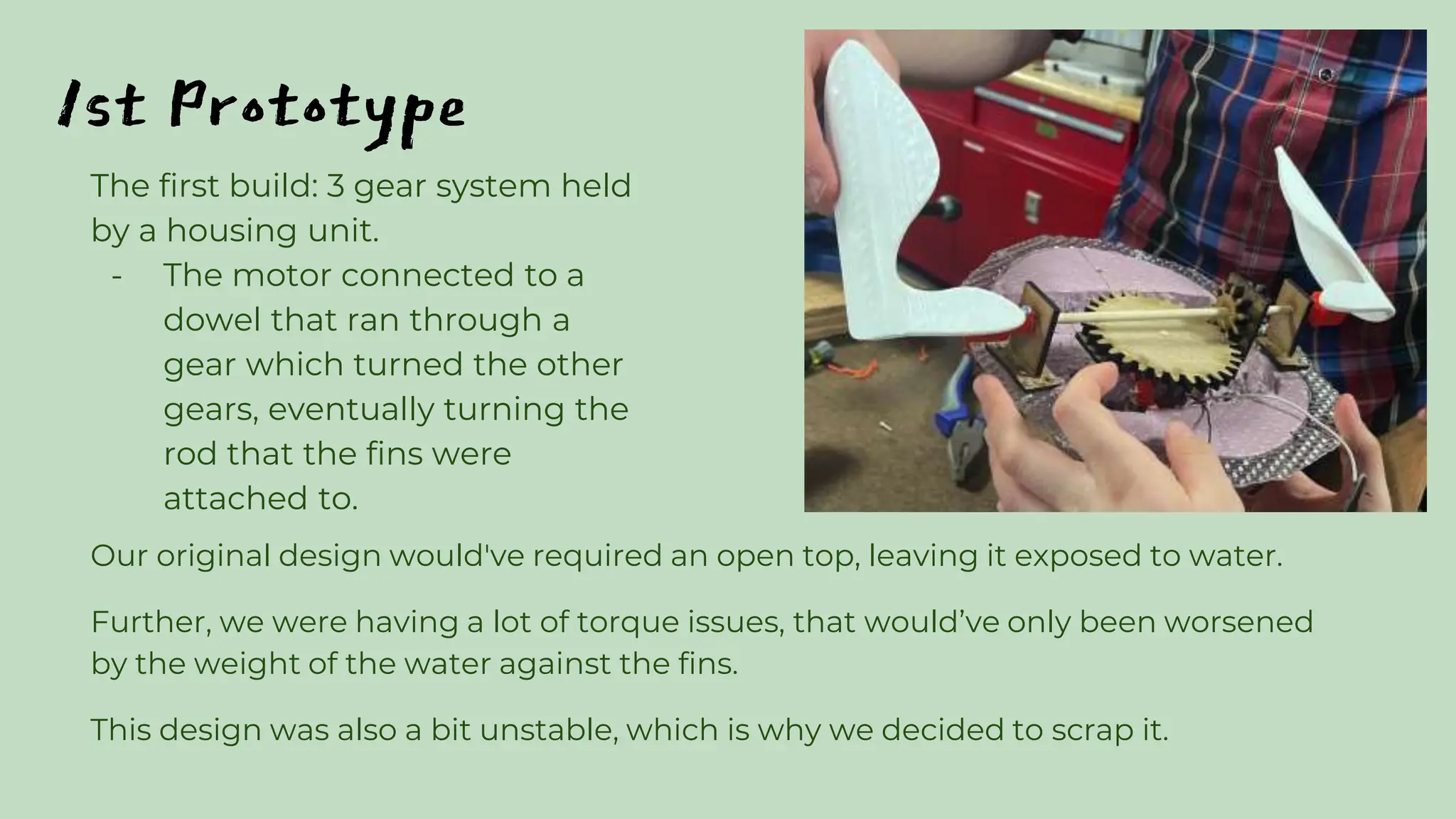

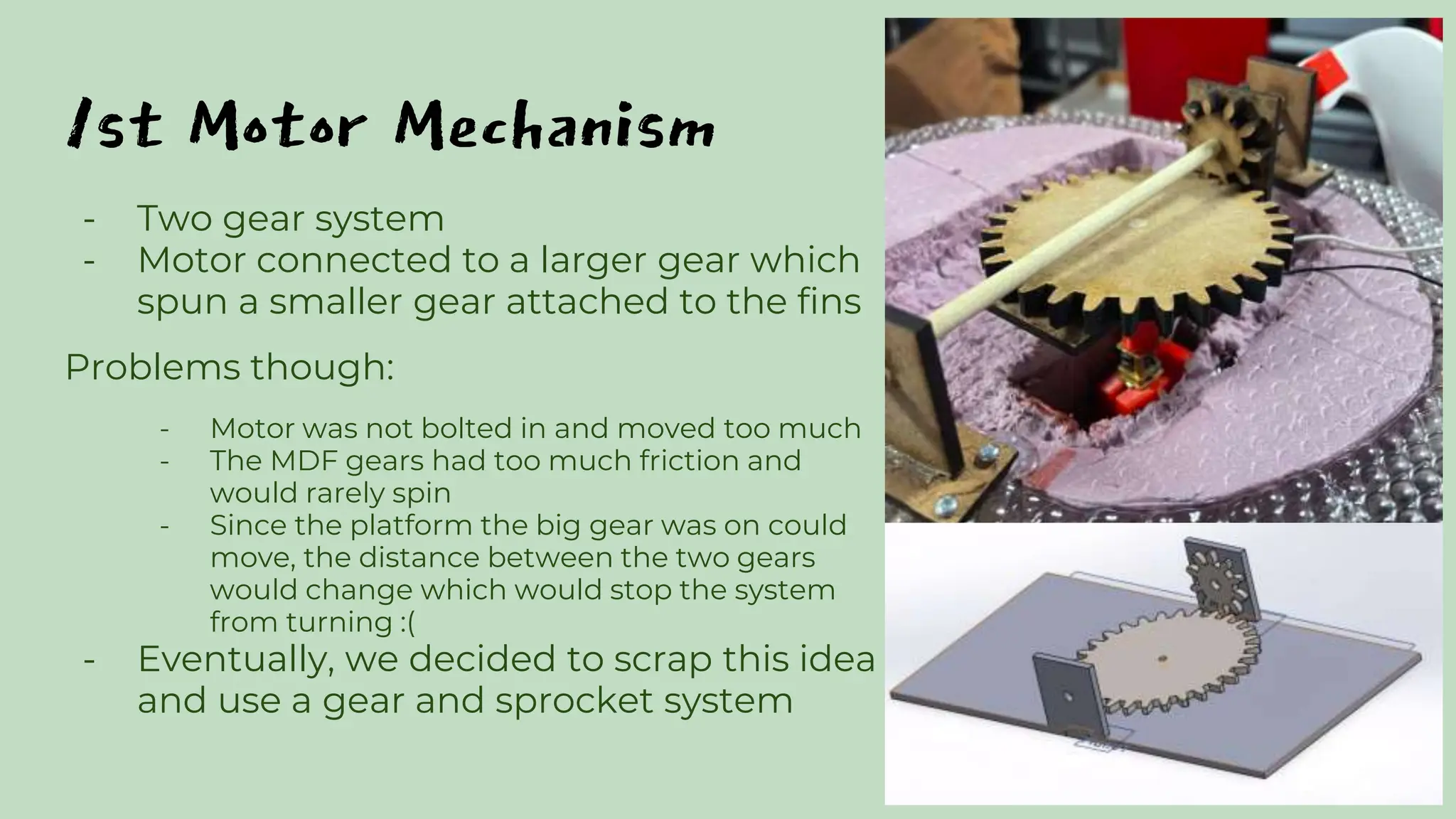

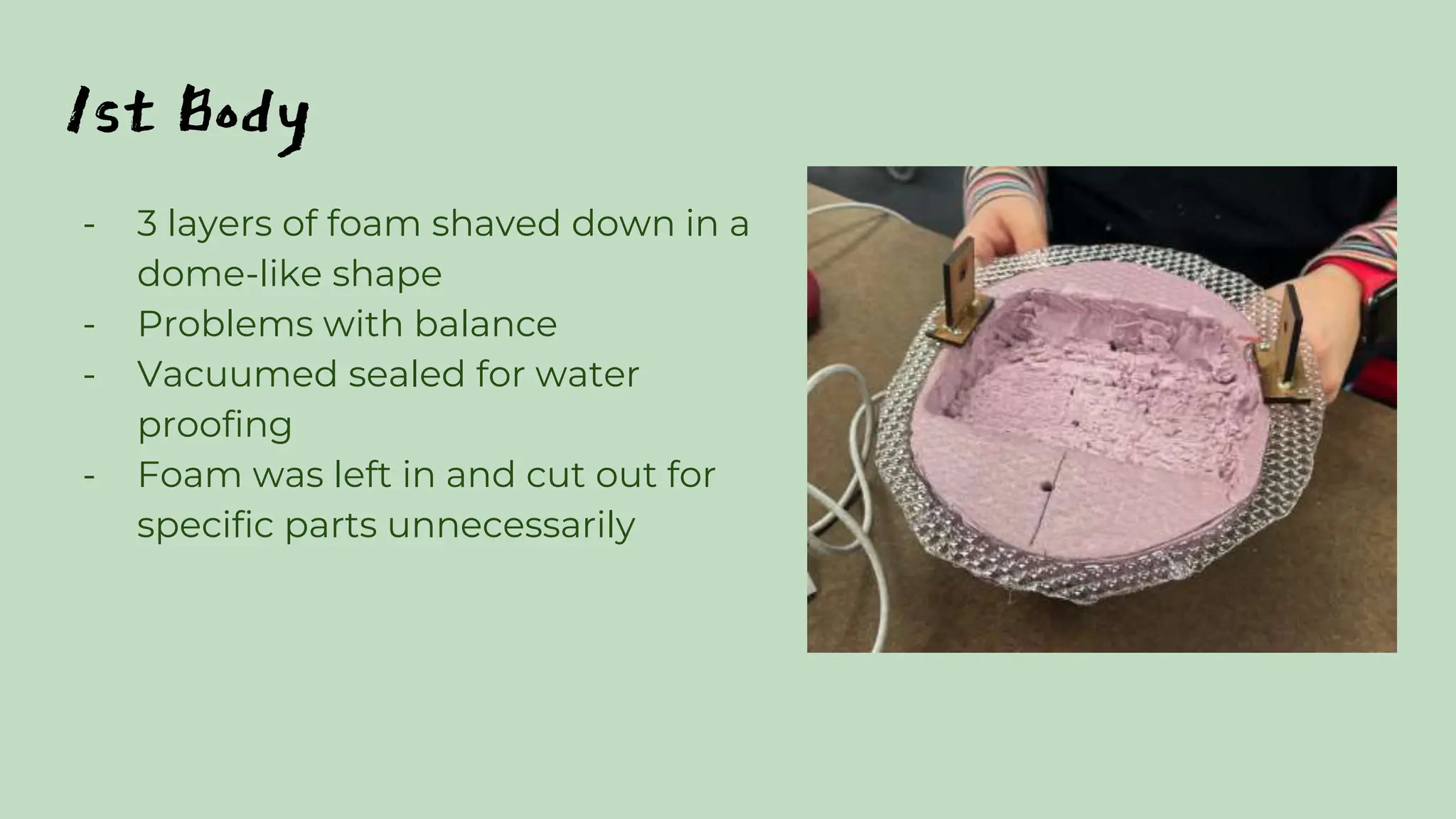

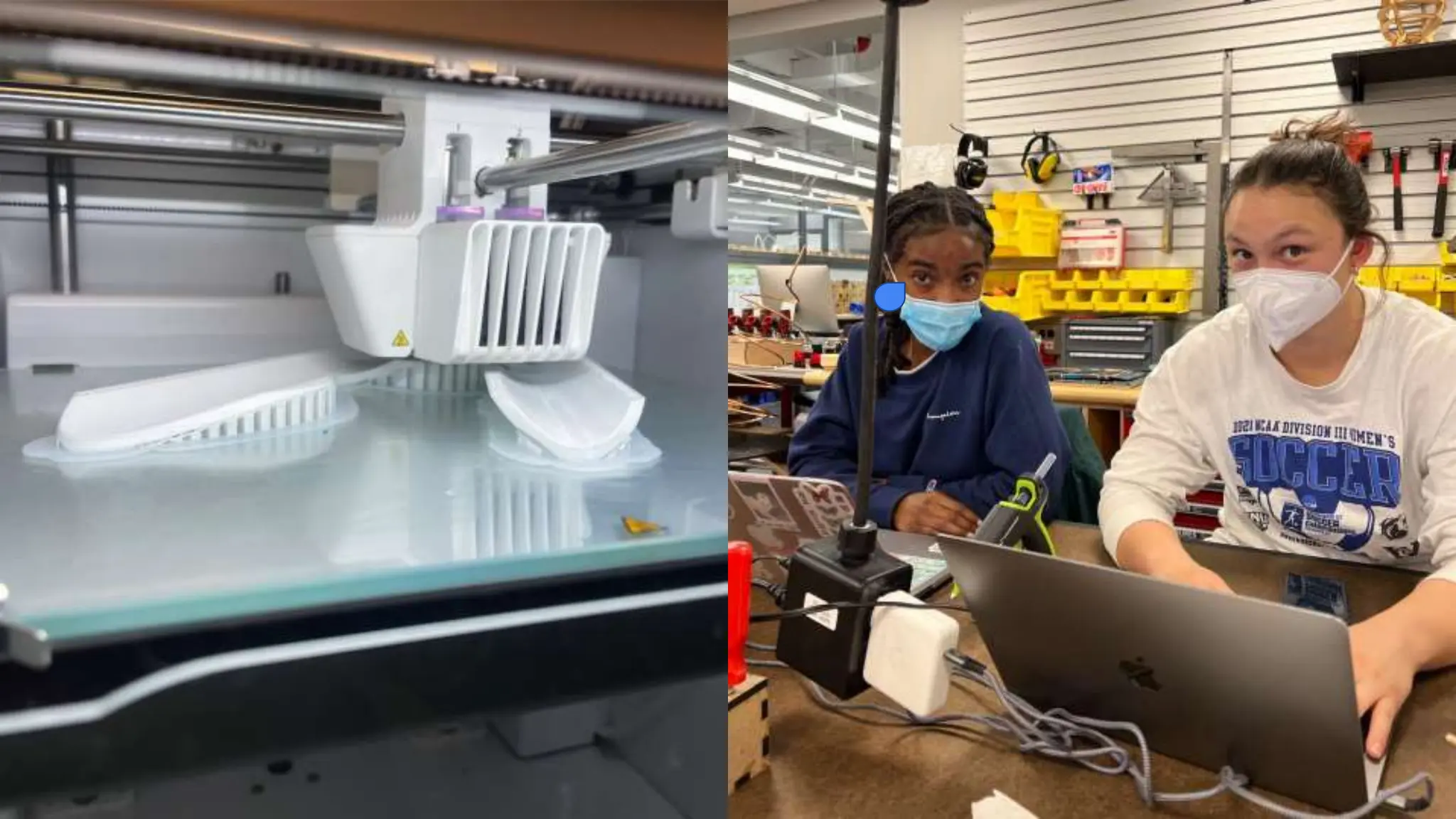

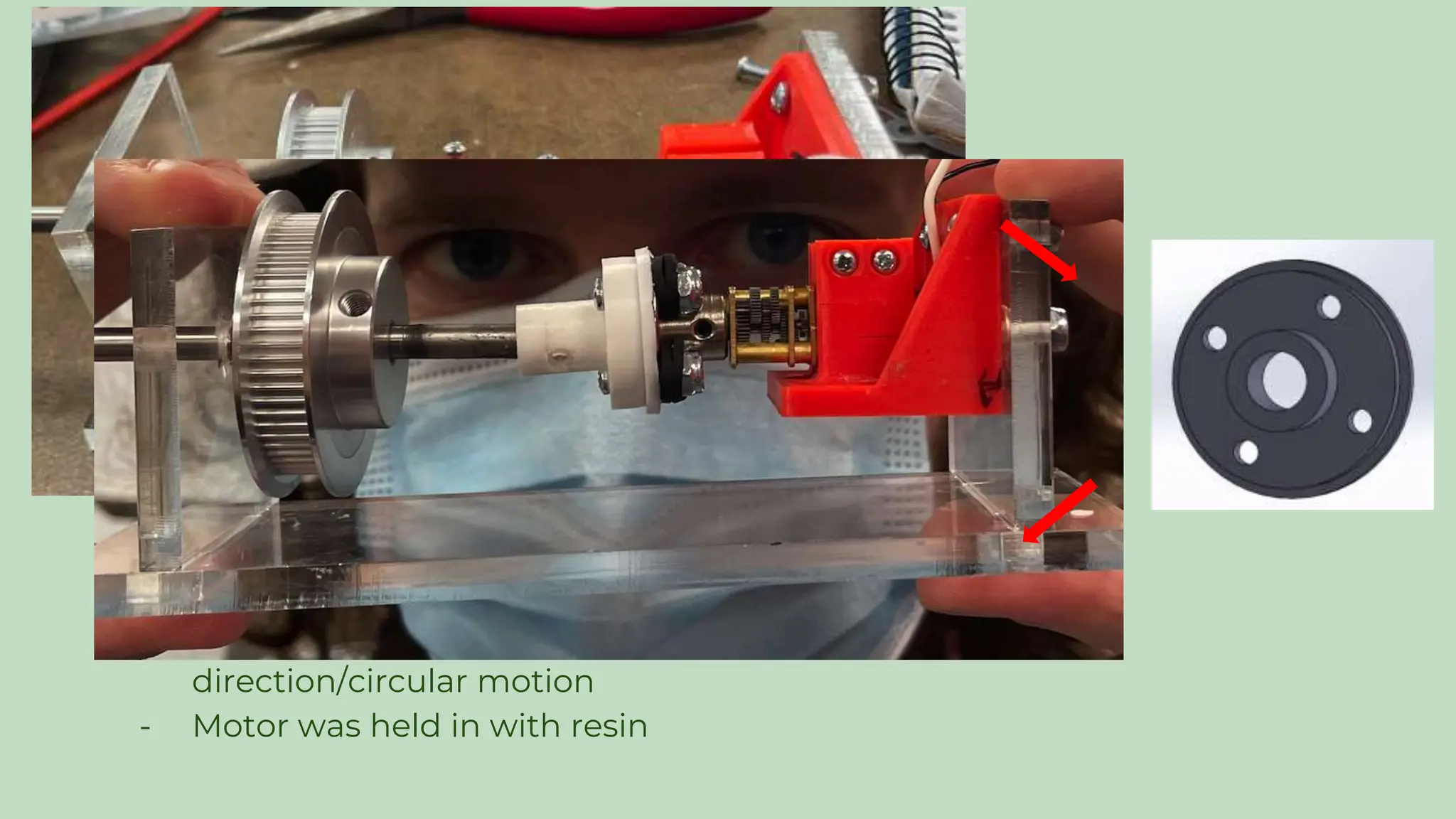

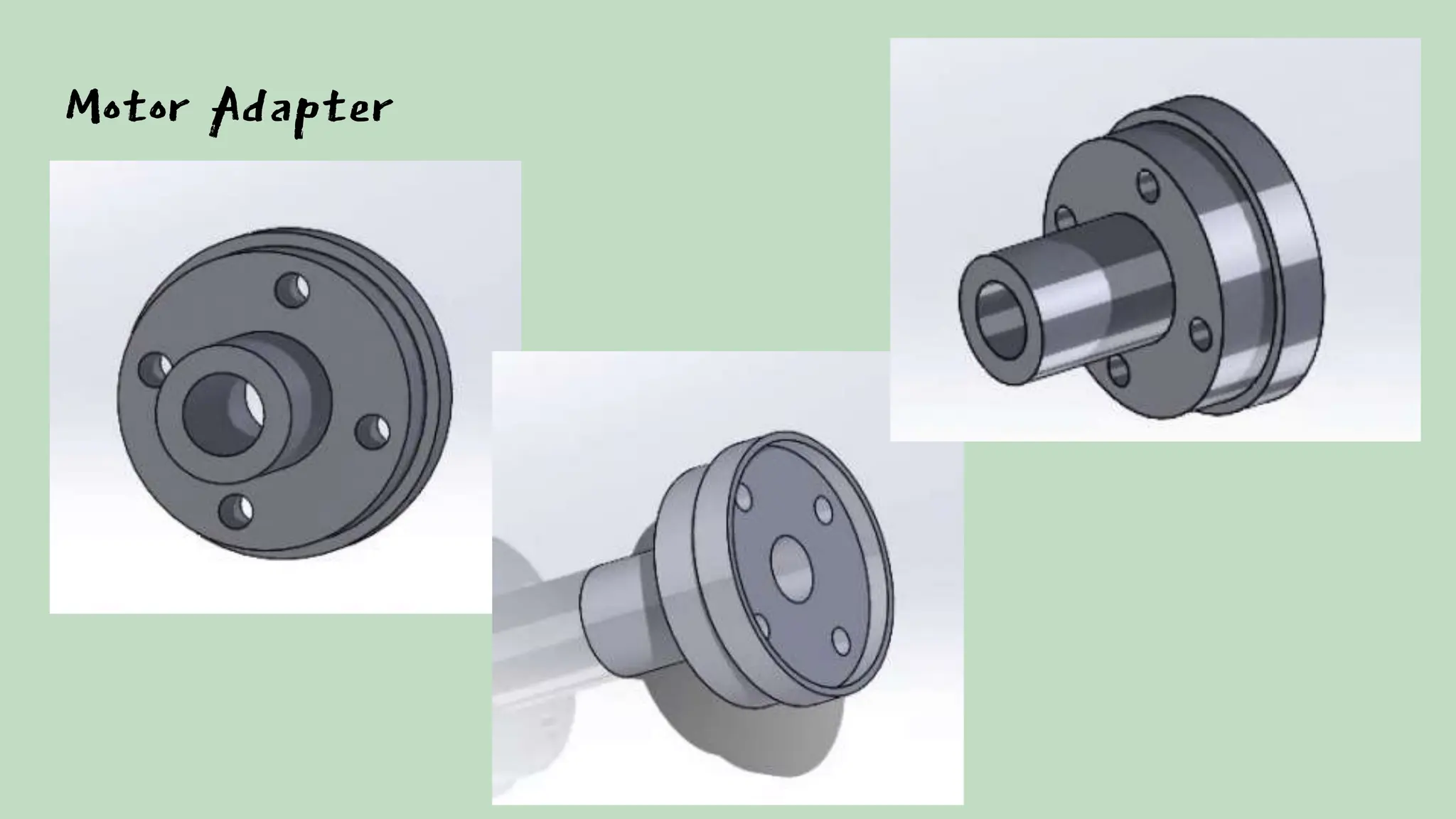

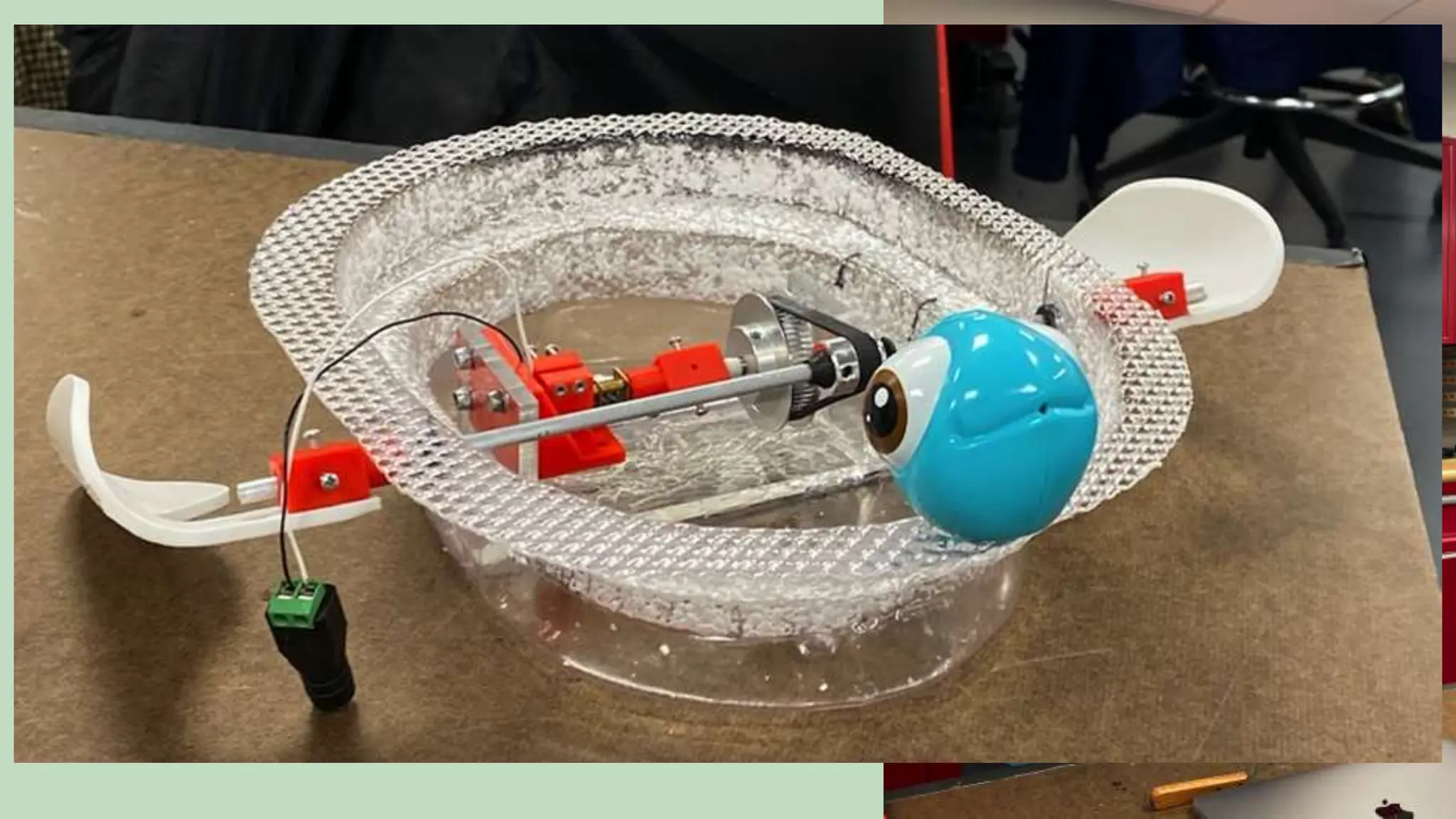

The team's goal was to create a 3D printed turtle with fins that rotate using a single motor. They designed multiple prototypes, starting with gears that had issues. Their final design used a closed timing belt system to connect the motor to a dowel rotating the fins. Challenges included waterproofing, unstable bodies, and motor mounts. Lessons learned included being open to new ideas, having backup systems, and how weight and placement impact function. The final prototype was able to swim across the tub using one motor to power the rotating fins.