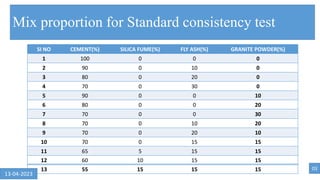

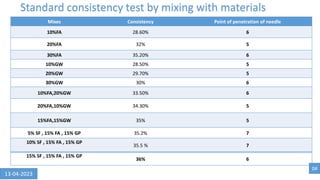

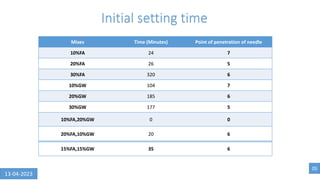

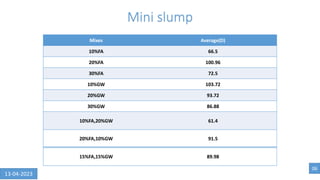

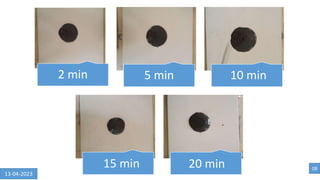

This document summarizes a student project on developing eco-efficient self-compacting concrete using silica fume, fly ash, and granite waste. The objectives are to determine the properties of materials, flowability of fresh concrete, and strength of hardened concrete. Mix proportions were developed with varying percentages of silica fume, fly ash, and granite powder. Standard consistency, initial setting time, mini slump flow, and compressive strength tests were conducted on the mixes. The project followed a methodology including literature review, material collection and testing, mix design, casting, curing, testing, and evaluation to meet objectives and have a successful outcome.