SB_INFO_C

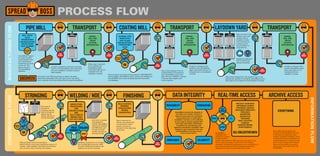

- 1. WELDING / NDESTRINGING FINISHING LAYDOWN YARDCOATING MILLPIPE MILL TRANSPORT TRANSPORT TRANSPORT BARGE, RAIL AND TRUCK SYSTEM INTEGRATION COATING TYPE INSPECTION TEST PLANS SPECIFICATIONS PROCEDURES QAQC BOL MANIFEST BARGE, RAIL AND TRUCK SYSTEM INTEGRATION BARGE, RAIL AND TRUCK SYSTEM INTEGRATION BOL MANIFEST REPORTS REPORTS REPORTS REPORTS REPORTS REPORTS REPORTS DOCUMENTATION REPORTS REPORTS REPORTS REPORTS REPORTS REPORTS REPORTS DOCUMENTATION INSPECTIONS PROCEDURES PQR SPECIFICATIONS NDE TALLY SHEETS REPAIR LOGS CUT OUT LOGS REPORTS REPORTS REPORTS REPORTS REPORTS REPORTS REPORTS DOCUMENTATION stencil data stencil data DB CF19 MILL TESTS QAQC PROCEDURES SPECIFICATIONS INSPECTIONS HEAT NUMBER VA LADATION ROUTINES VA LADATION ROUTINES VA LADATION ROUTINES VA LADATION ROUTINES VA LADATION ROUTINES VA LADATION ROUTINES BOL MANIFEST INVENTORY YARD SUMMARY BOL MANIFEST VA LADATION ROUTINES VA LADATION ROUTINES VA LADATION ROUTINES STATION ID SURVEY stencil data DB WELD NUMBER WELDER CERTS FIELD COATING BENDING HYROTESTING DRYING CALIPER PIGS PROJECT OVERVIEW PROGRESS CHARTS PROGRESS GRAPHS WEATHER FORECASTS TIMELINES INVENTORY SCHEDULES TRACKING MAP LOCATION DAMAGE DAMAGE REPAIR MAINTANENCE ALL COLLECTED DATA EVERYTHING REPORTS REPORTS REPORTS REPORTS REPORTS REPORTS REPORTS DOCUMENTATION PROCESS FLOWMANUFACTURINGFLOWCONSTRUCTIONFLOW INFORMATIONFLOW SpreadBoss® begins by capturing data, documentation and any maintenance issues that occurred at the mill. The data is stored in the SpreadBoss database. As pipe is loaded for shipment via barge, truck or rail, SpreadBoss scans each pipe and runs validation routines to ensure data integrity. Docuvista® uses OCR technology to capture all paper documents associated with your pipe, so you can easily store, organize, track and retrieve them through SpreadBoss. When pipe is received at the coating mill, SpreadBoss again scans each pipe as it is unloaded and runs validation routines. Once all pipe is received and accounted for, FBE/ARO/CWC coating begins. SpreadBoss scans, checks and validates our barcode/RFID, then enters all phase-specific information into database. Pipe is then shipped from the coating facility to the laydown yard. SpreadBoss scans each pipe and runs validation routines to ensure data integrity and verify shipment. As pipe is received at the laydown yard, SpreadBoss again scans each pipe as it is unloaded and runs validation routines. As pipe is received at the spread, SpreadBoss again scans each pipe as it is unloaded and runs validation routines. Pipe is stored in the laydown yard until needed. Pipe is checked to make sure barcodes are in place and all documentation is accounted for. Weather forecasts and joint locations are always accessible. Pipe is then shipped from the laydown yard to the appropriate spreads for stringing. SpreadBoss scans each pipe as it is loaded running validation routines. Data is captured on reports and entered into our document control system, and can be included in final reporting for as-built. SpreadBoss interfaces with almost any system. It captures shot points, weld numbers, NDE data and other data in the field, so you can access it in real time, as it’s being collected. The graphic interface give you a vivid picture of your entire spread, and all the survey/as-built data is integrated to create one seamless flow of data. Each joint is scanned at stringing, and the data is compared against the ID stencil, OD stencil and the barcodes. GPS and Station ID’s are recorded to identify where a joint was originally strung out. If needed, ‘sight-readable’ barcodes can be placed onto joints for future tracking and reading. Each joint is welded and assigned a number. SpreadBoss captures all welding and NDE data, and records the weld number and the up and down joints. Validation routines are run to ensure the multiple data points are 100% accurate. Welding procedures and welders can also be recorded. ® ARCHIVE ACCESSREAL-TIME ACCESSDATA INTEGRITY ASBUILT WELD NUMBER SURVEY GIS ® Once data and documents are entered into SpreadBoss, they can be accessed by approved users anytime, anywhere. Whether you’re verifying the billing and delivery of a recent shipment, or trying to track down 5-year old pipe from a faulty heat, the information you need is always just a few clicks away with SpreadBoss. DATA INTEGRITY DATA INTEGRITY DATA INTEGRITY DATA INTEGRITY DATA INTEGRITY DATA INTEGRITY DATA INTEGRITY DATA INTEGRITY DATA INTEGRITY VA LADATION ROUTINES TRACEABILITY VERIFICATION COMPLIANCE RELIABILITY SpreadBoss protects the integrity of your data on a number of fronts: It reduces human error by minimizing manual data entry. It makes data available in real time, as it’s collected, so your team is always working with up-to-date information. Monitoring compliance for specification and regulatory standards is simplified. Data integrity is more important than ever and SpreadBoss is the best way to ensure and protect it.