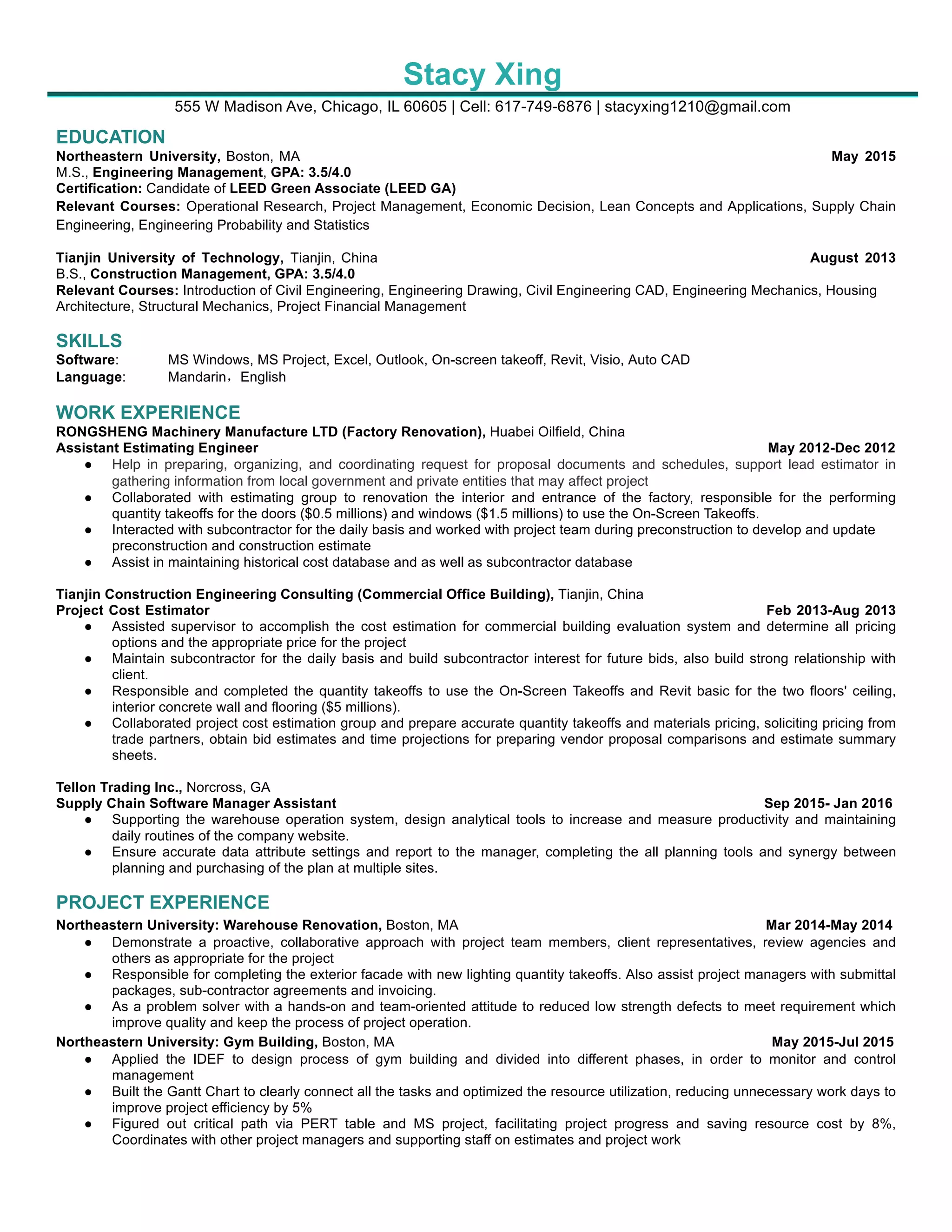

Stacy Xing has over 5 years of experience in construction management, cost estimating, and supply chain management. She holds a Master's degree in Engineering Management from Northeastern University and a Bachelor's degree in Construction Management from Tianjin University of Technology. Her previous roles include assistant estimating engineer, project cost estimator, and supply chain software manager assistant. She has experience completing quantity takeoffs, maintaining cost databases, and applying project management tools like IDEF, Gantt charts, and PERT tables to optimize schedules and resource utilization. Currently, she is seeking new opportunities in project management, construction, or supply chain fields.