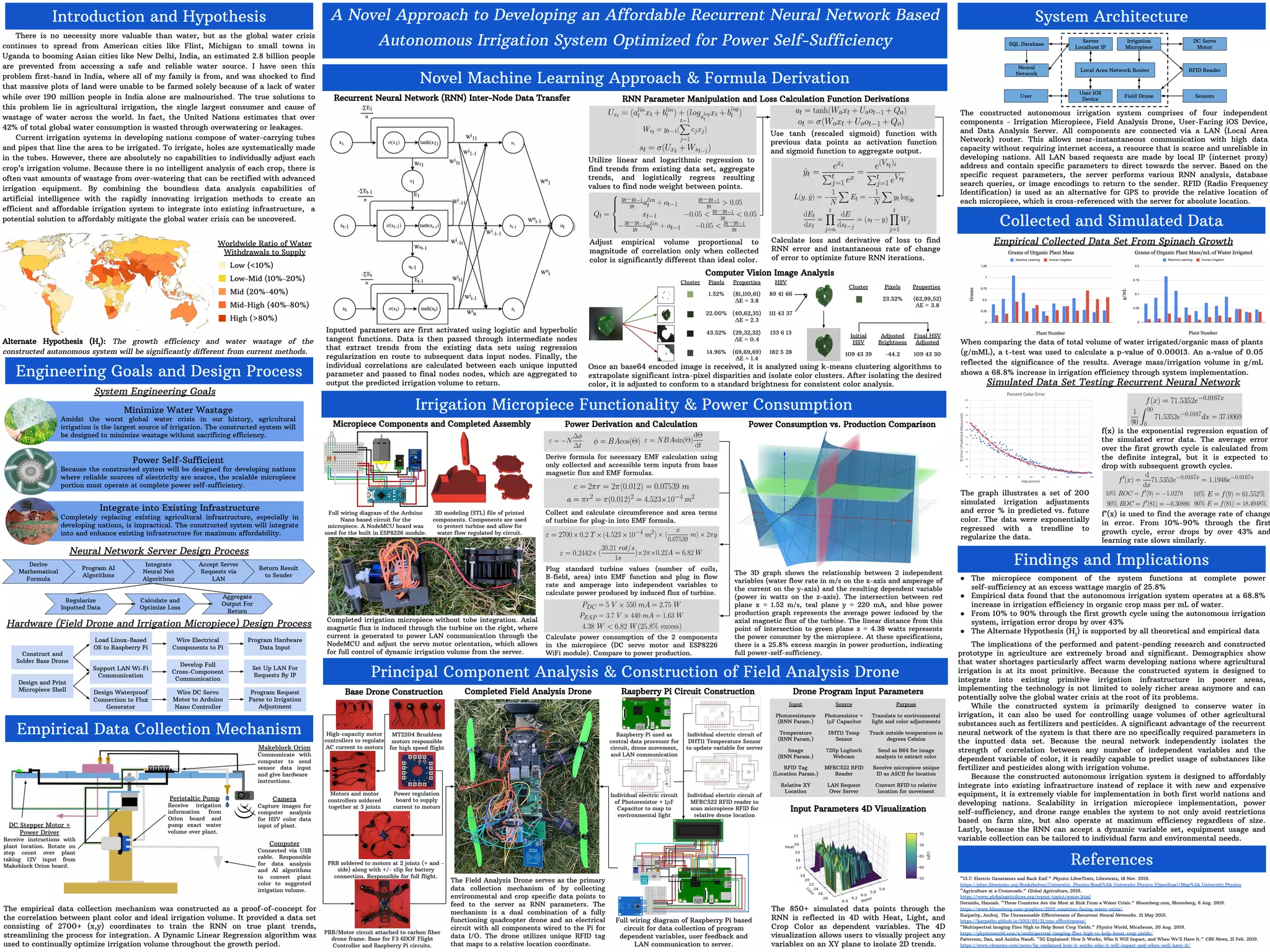

The autonomous irrigation system operates more efficiently than current methods, reducing irrigation errors by over 43% and increasing crop yield per water volume by 68.8%. It integrates into existing infrastructure in developing countries through self-sufficient micropieces powered by on-site water turbines. Recurrent neural networks analyze environmental and crop data to minimize water waste without compromising growth. This novel approach could help address the global water crisis through optimized agricultural irrigation.