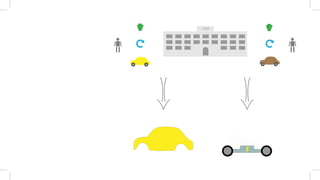

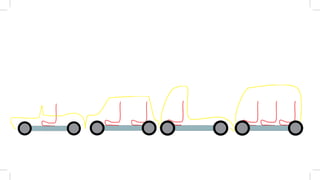

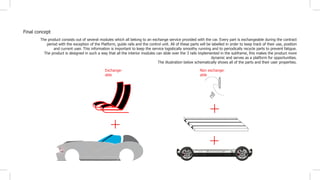

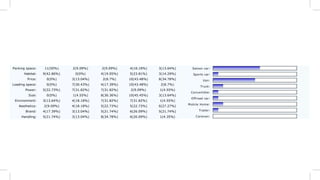

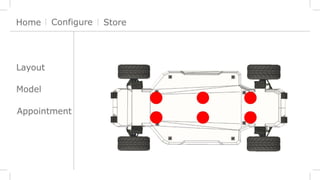

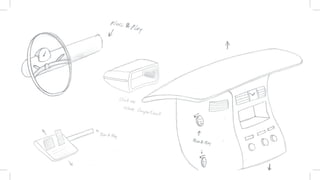

This document provides a summary of a student project on designing an electric vehicle. The project aims to introduce electric cars in the short term through a product service system that provides customers with different body styles on a subscription basis. This would help sustain the automotive industry during the transition to electric vehicles. The student conducted research on past electric vehicle studies, spoke with experts, and did brainstorming. A survey was also administered to understand target customers' needs. The resulting concept includes interchangeable interior modules that can be easily configured to different layouts through a rail system in the vehicle base. The goal is to provide customers with different "bodies" through the subscription service.