Embed presentation

Download to read offline

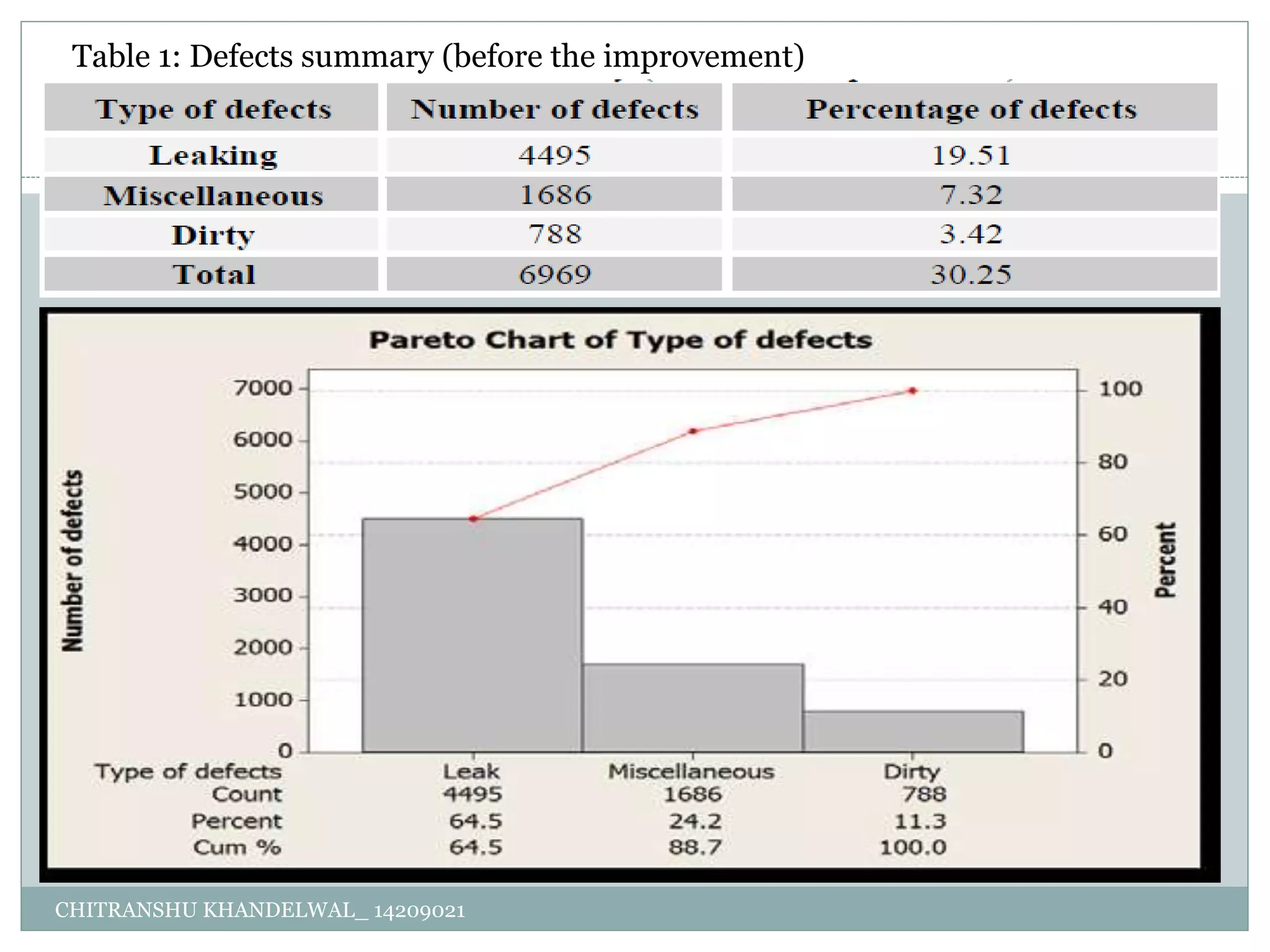

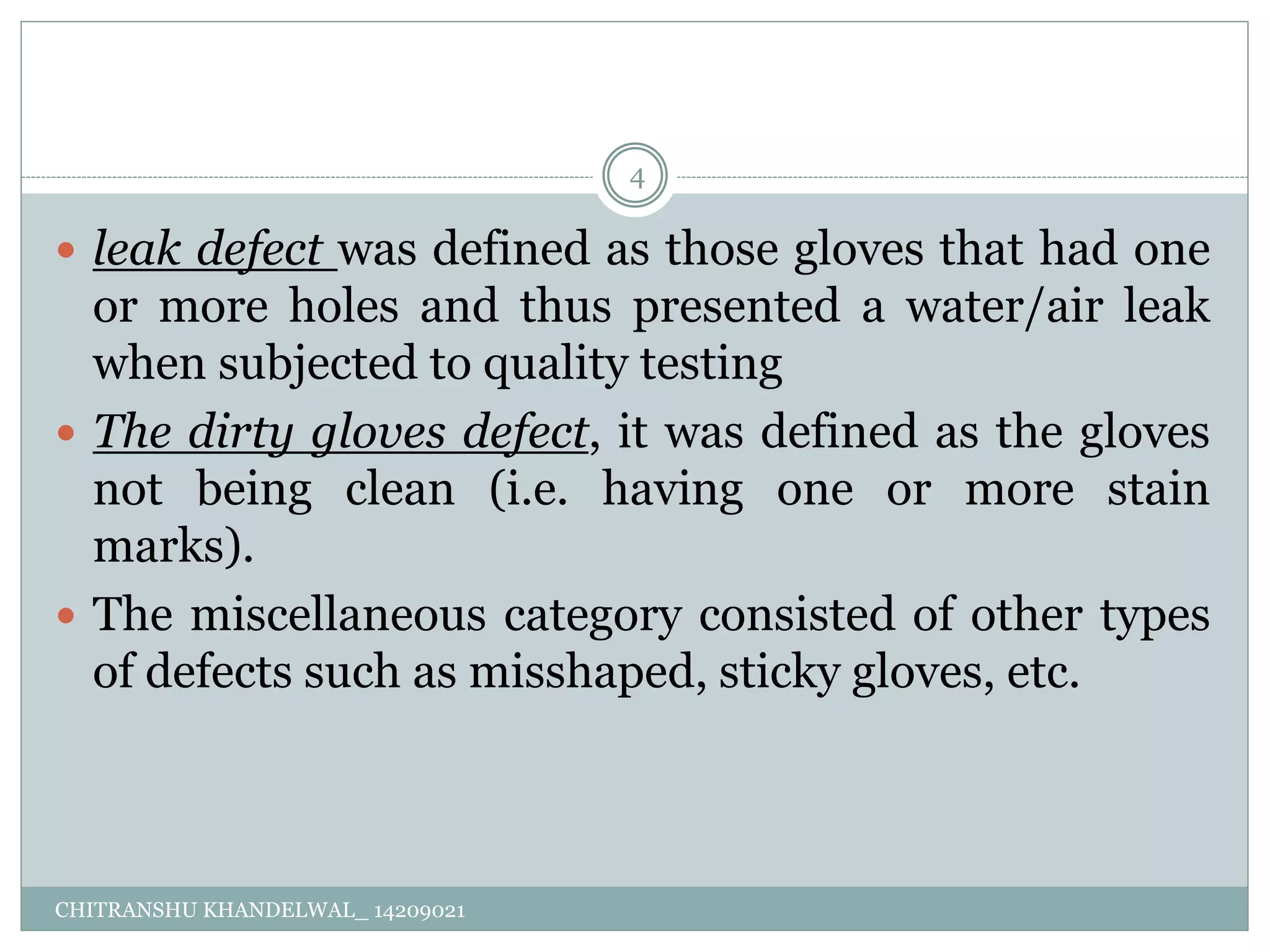

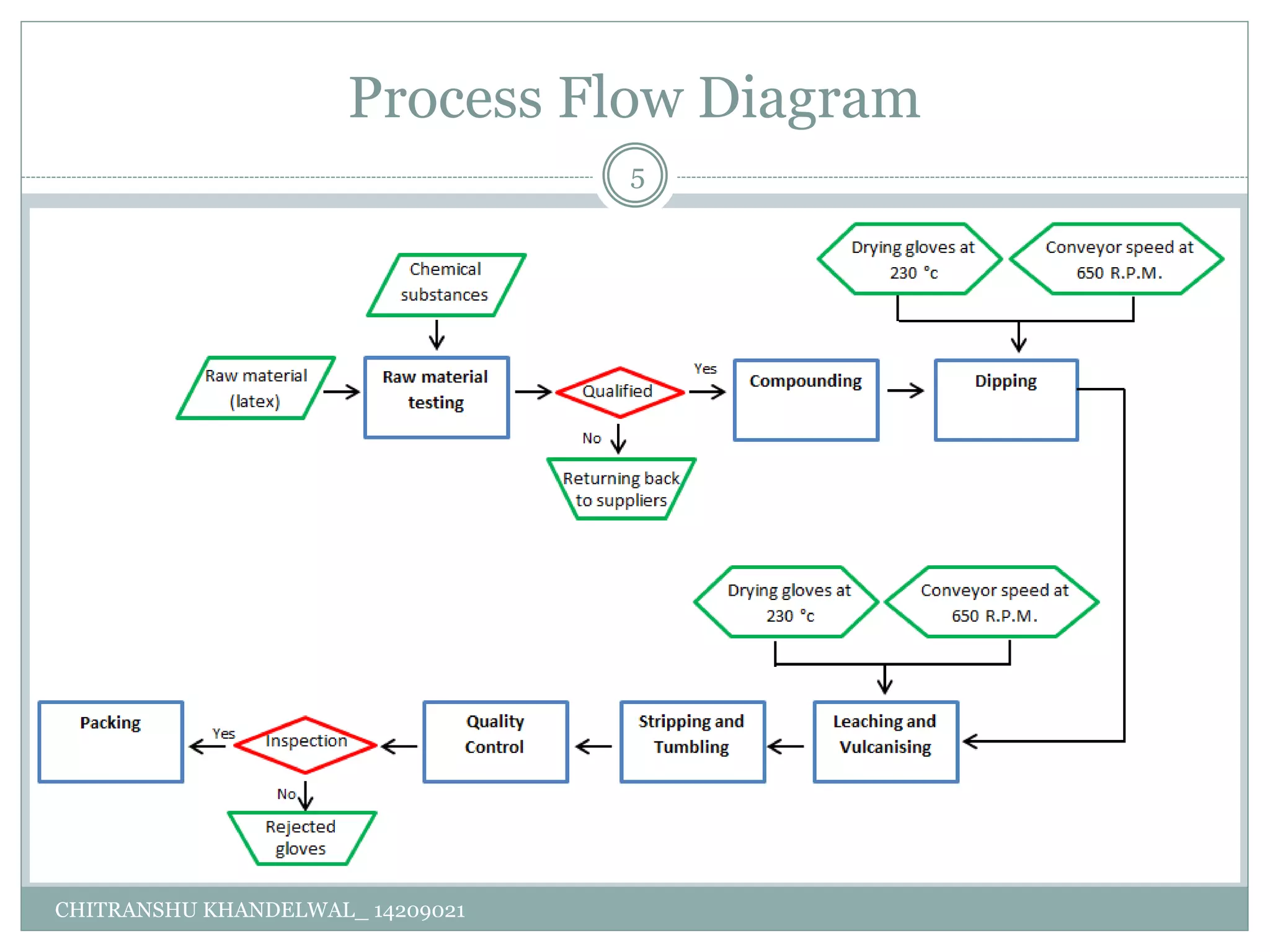

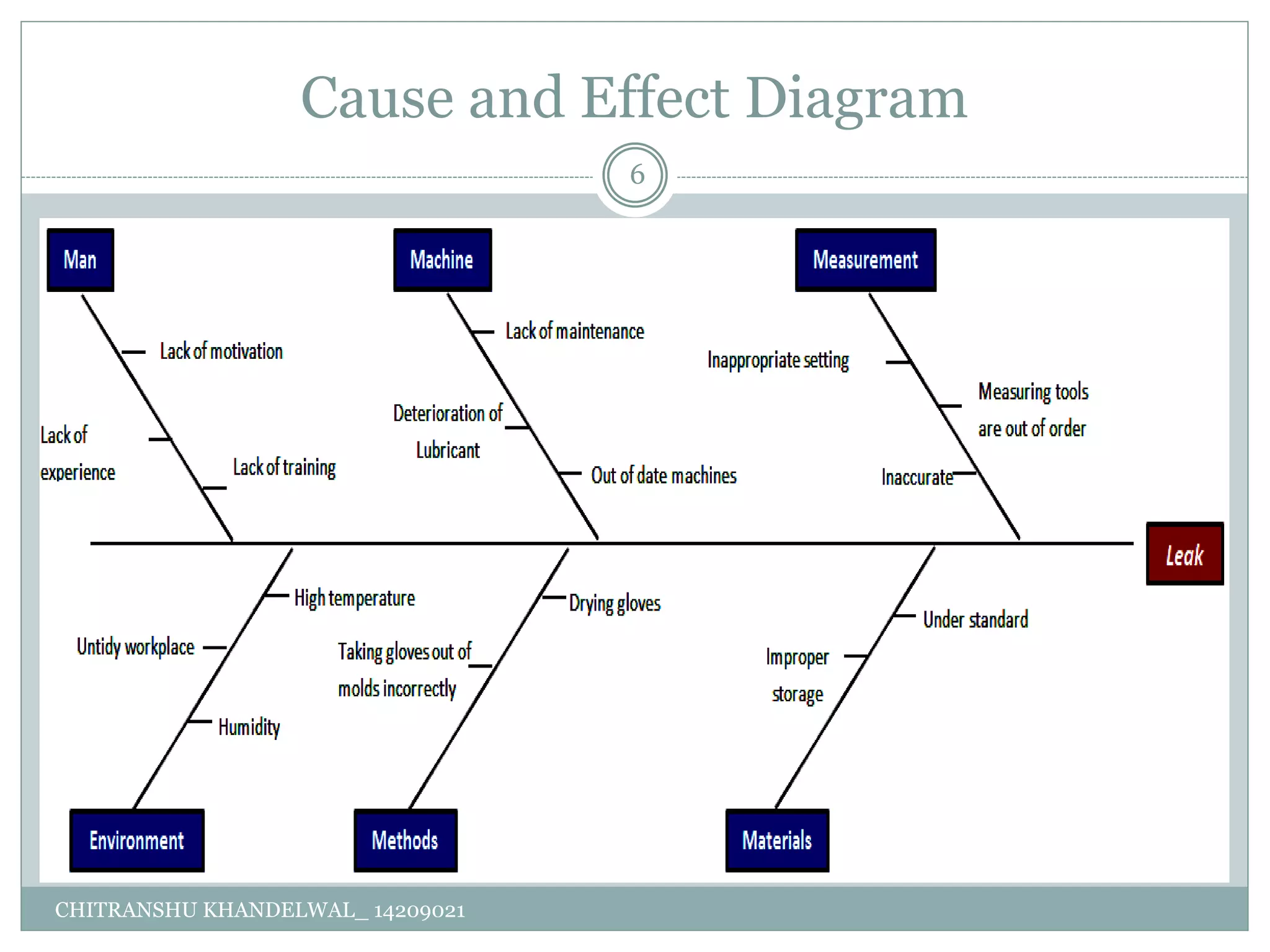

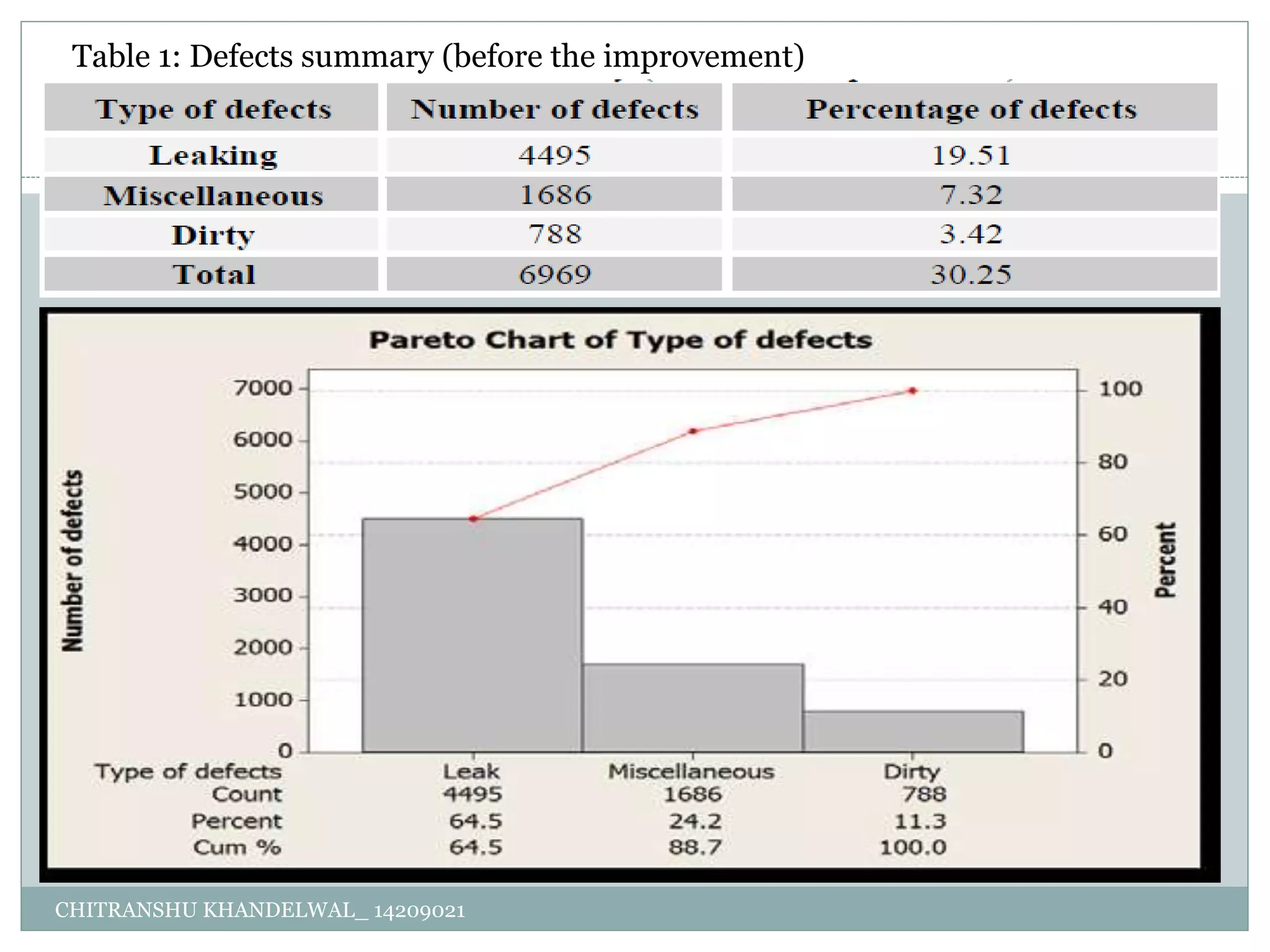

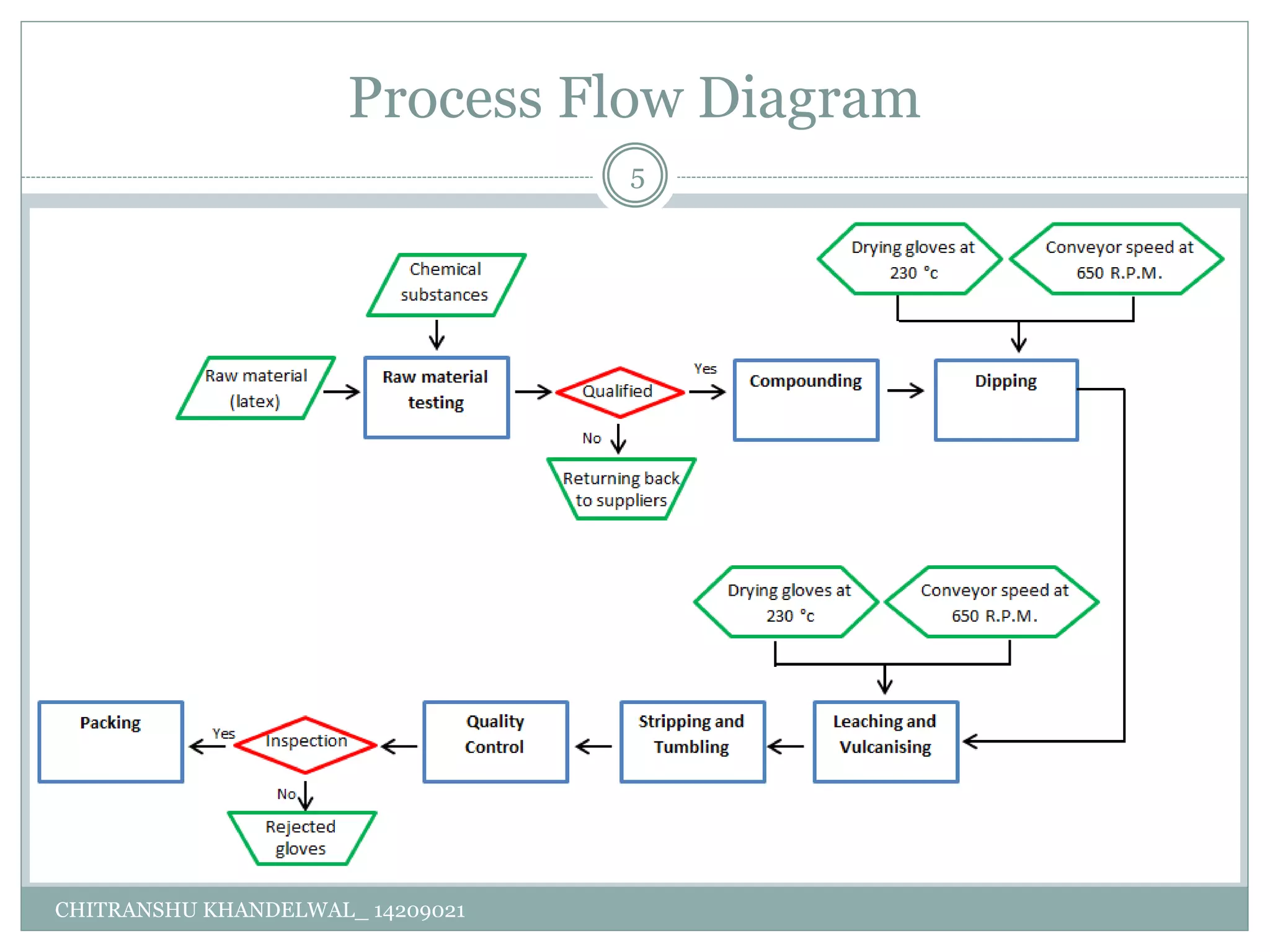

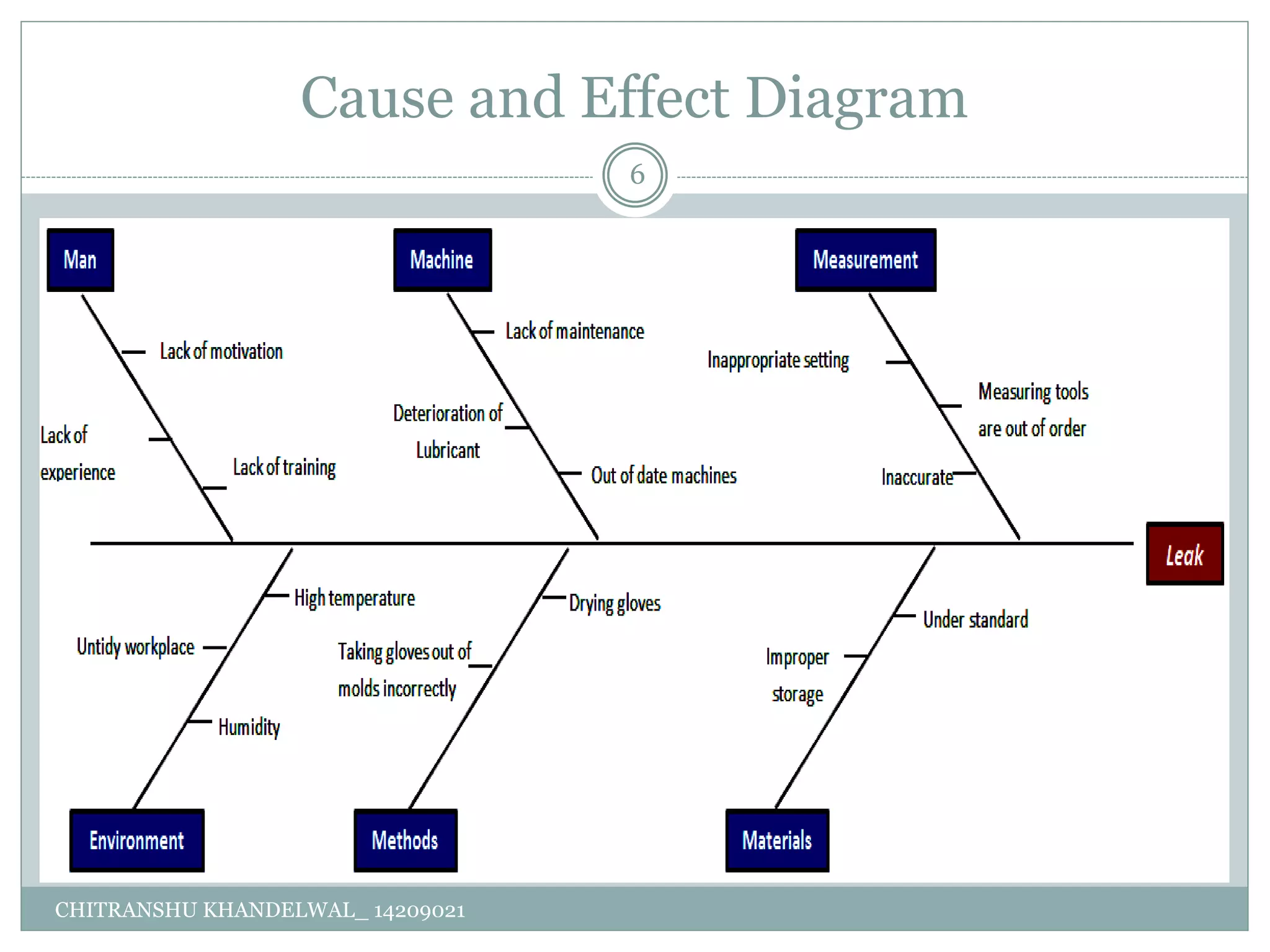

This case study analyzed defects in a rubber glove manufacturing process. It identified the main defect types as leaks, dirty gloves, and miscellaneous issues. To address these, it created a process flow diagram and cause-and-effect diagram to understand root causes. Experiments were conducted varying temperature and conveyor speed in the process. The results showed setting the temperature to 230°C and conveyor speed to 650 RPM significantly reduced leaks, lowering the defects per million from 195,095 to 83,750 and improving the sigma level from 2.4 to 2.9.