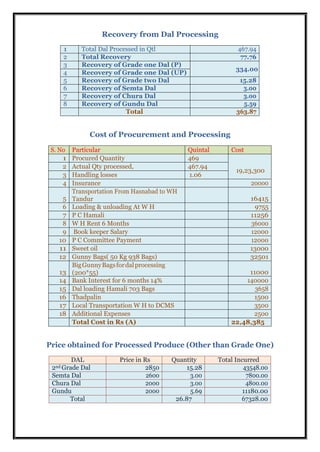

The report analyzes the processing of red gram (tur dal) by farmer producer companies in Kodangal and Hasnabad, detailing the procurement, processing, and marketing efforts aimed at enhancing farmers' income. Challenges identified include quality control issues, high processing costs, and difficulties in finding buyers due to increased prices and decreased quality compared to competitors. Recommendations include better quality monitoring during procurement and processing, a solid marketing strategy, and ensuring safe storage of materials to prevent losses.