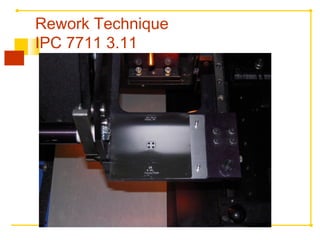

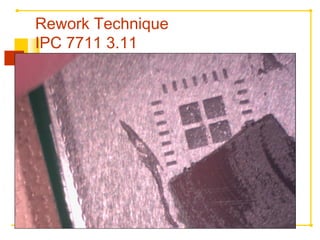

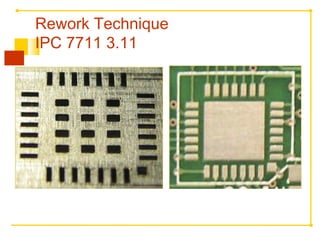

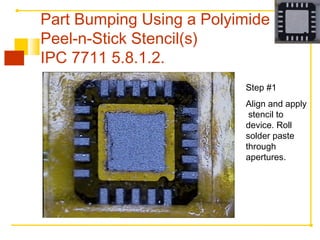

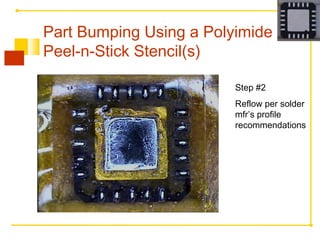

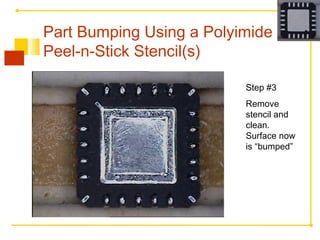

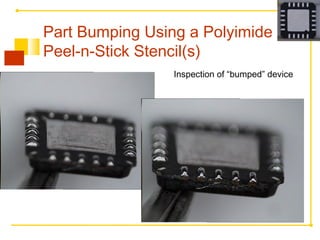

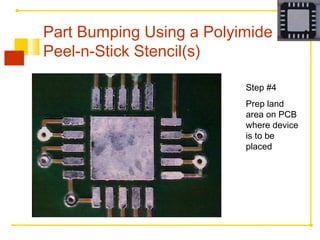

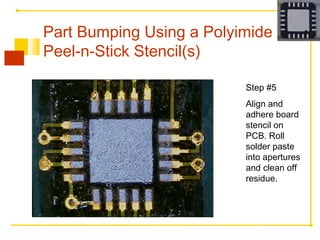

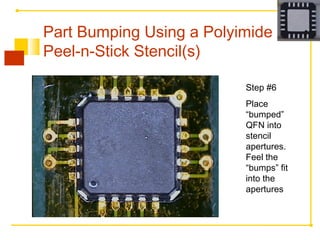

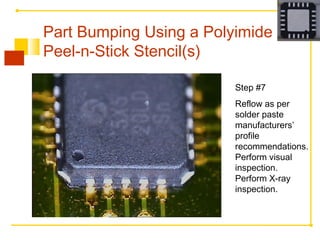

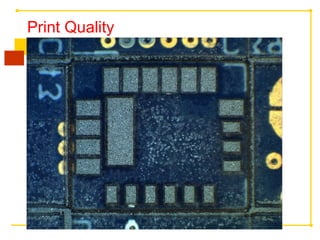

The document outlines a detailed process for reworking QFN (Quad Flat No-lead) packages according to IPC 7711 standards. It includes steps such as aligning and applying the stencil, rolling solder paste, reflowing, and inspection of the device. The process emphasizes the use of polyimide peel-n-stick stencils for part bumping and solder applications.