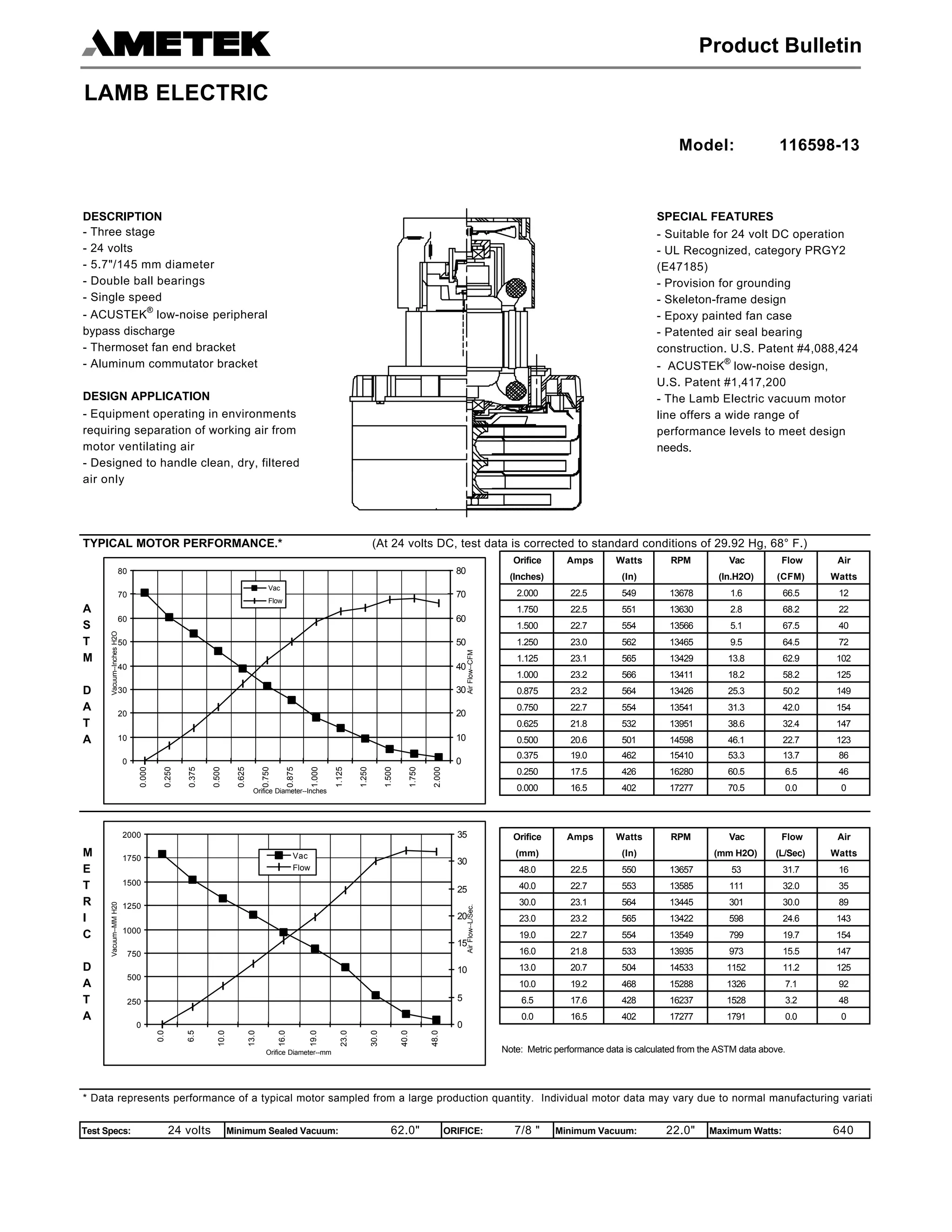

The document outlines the specifications and performance data of a range of lamb electric vacuum motors operating at 24 volts DC. It includes detailed metrics such as orifice size, airflow, vacuum, power consumption, and dimensions, while highlighting special features like low-noise design and patented technology. Important safety warnings regarding the use of these motors in specific environments are also provided.