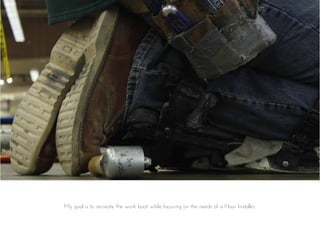

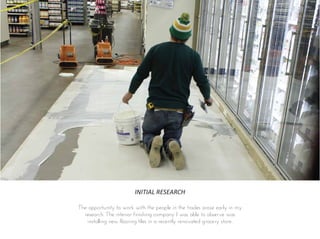

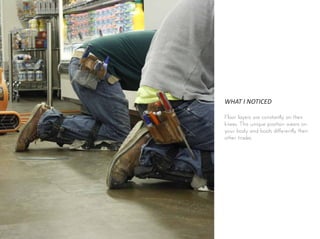

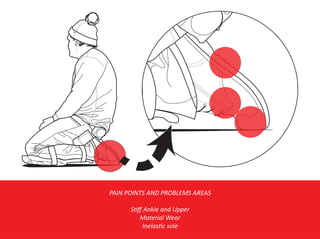

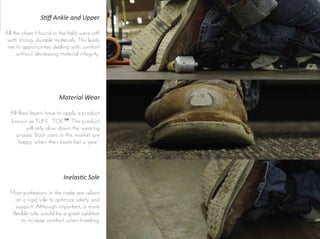

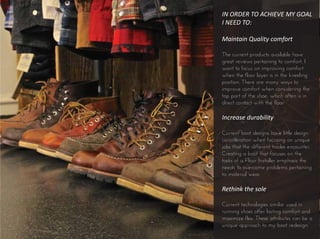

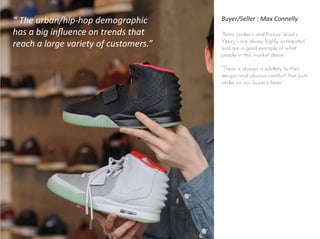

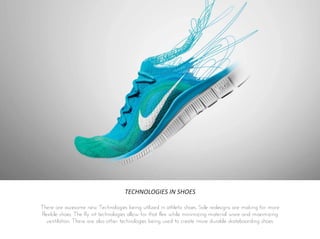

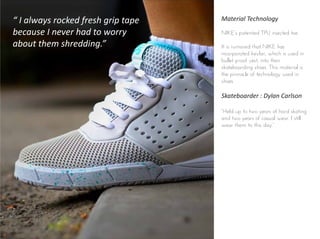

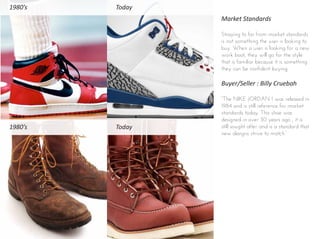

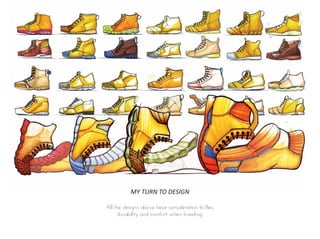

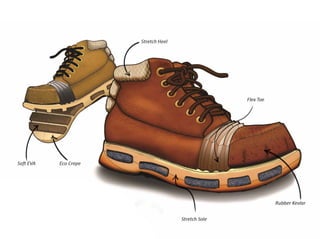

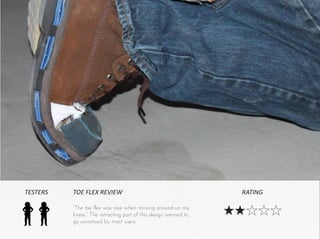

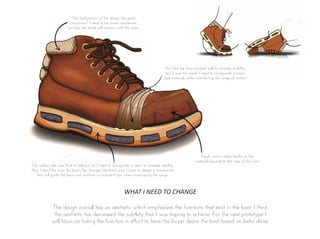

The document summarizes research and design work for a specialized work boot for floor installers. Initial research involved observing floor installers and identifying pain points like material wear, stiff ankles, and inelastic soles. Trends, technologies, and market standards were also considered. A first prototype incorporated a stretch sole, toe flex, and rubber kevlar material. User testing of the prototype found the sole and toe flex comfortable but the material and stability needing improvement. The designer plans to focus the next prototype on hiding functionality to increase buyer desirability while addressing issues like a rigid toe flex area, expanded rubber coverage, a tapered sole for stability, and consistent sizing during flex.