- This document presents a project review for the design and analysis of a crop cutter machine by three students under the guidance of an assistant professor.

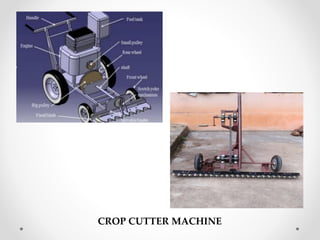

- The project aims to design a small, mechanized crop cutter to replace manual crop cutting methods which are time-consuming and require significant labor.

- The proposed crop cutter machine would use a petrol engine to power a cutting roller and blade to quickly cut crops, reducing the time and costs of harvesting for small-scale farmers.