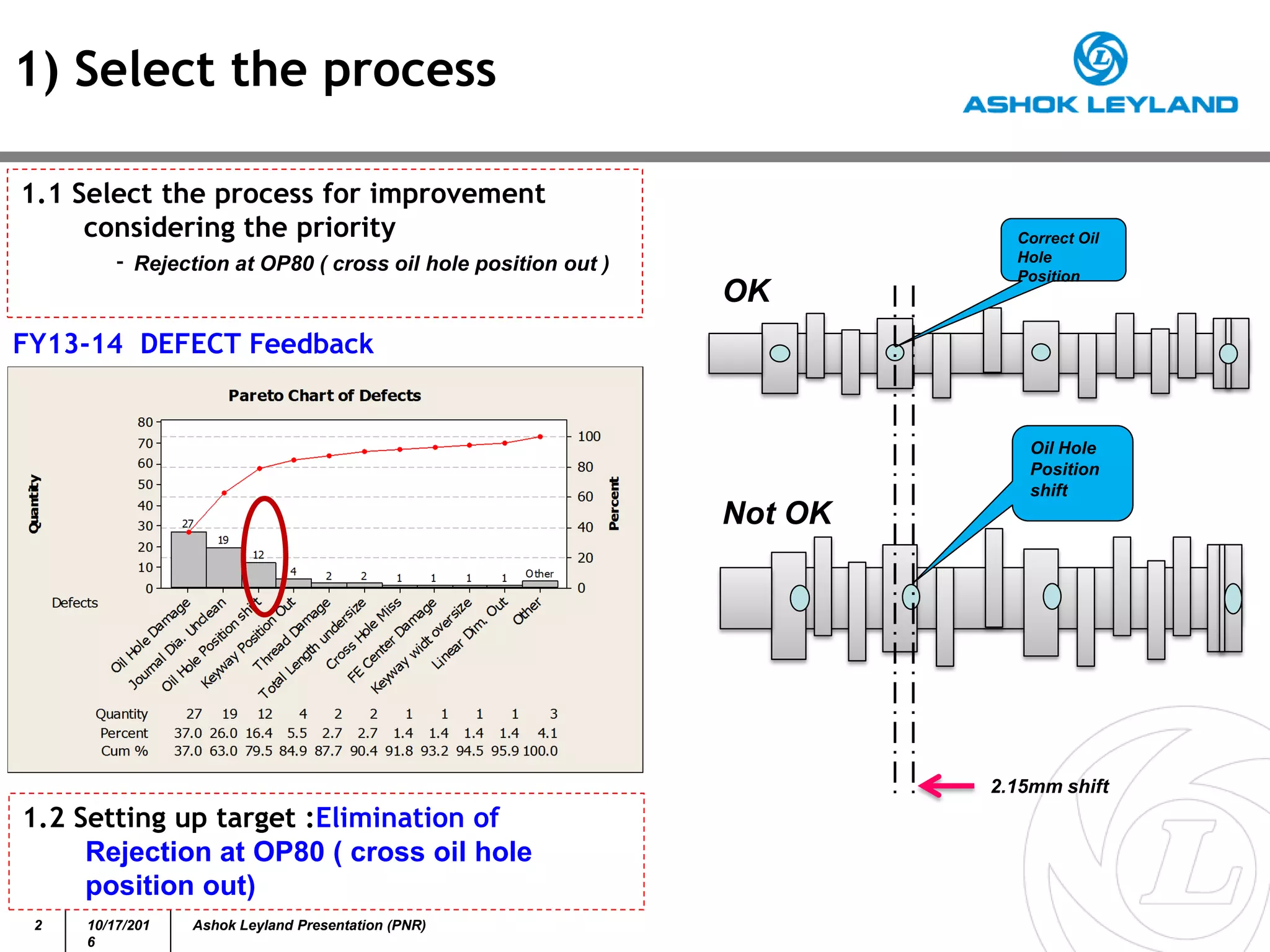

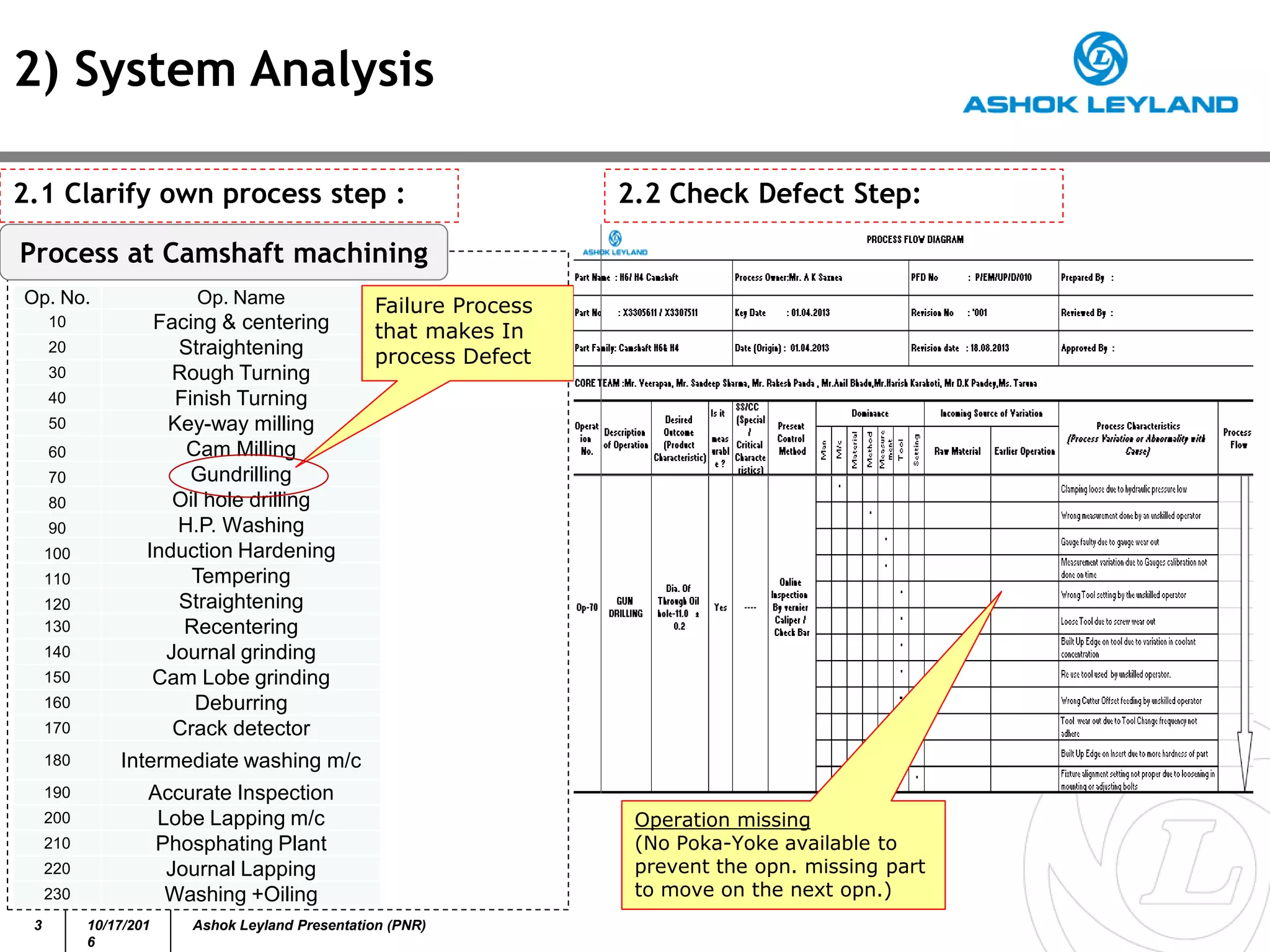

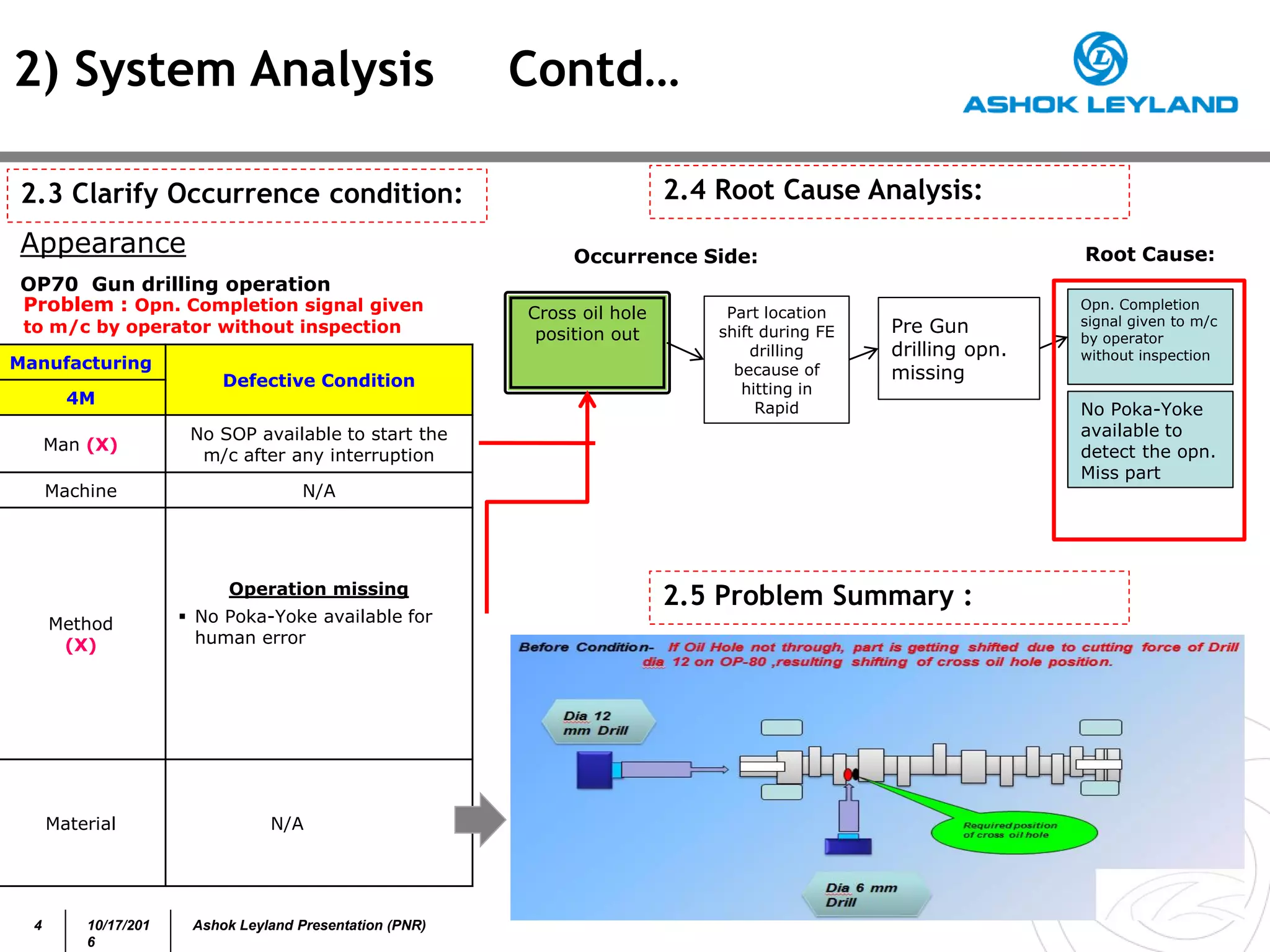

This document summarizes a project to eliminate rejections at Operation 80 due to missing the cross oil hole operation. The project involved:

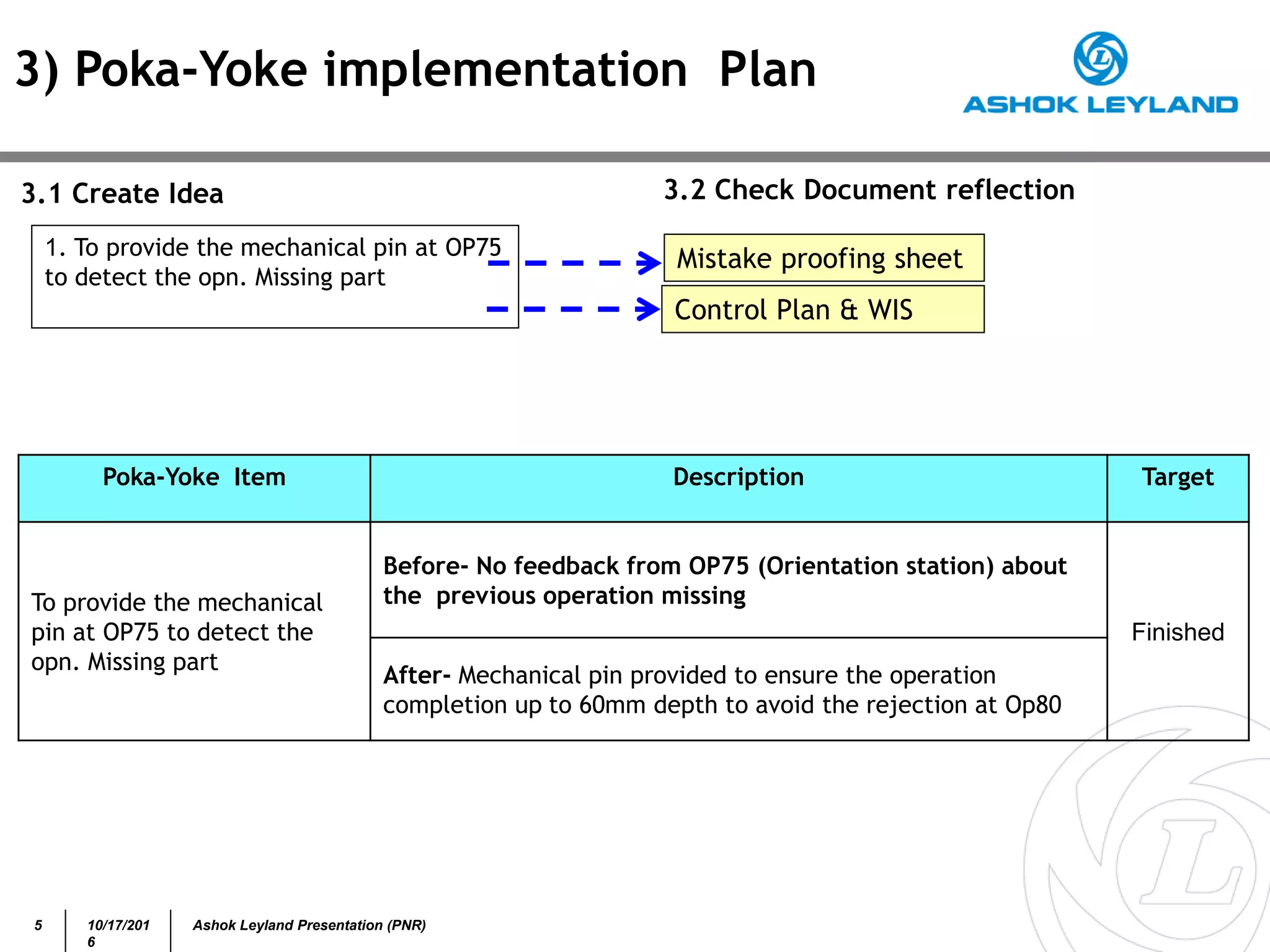

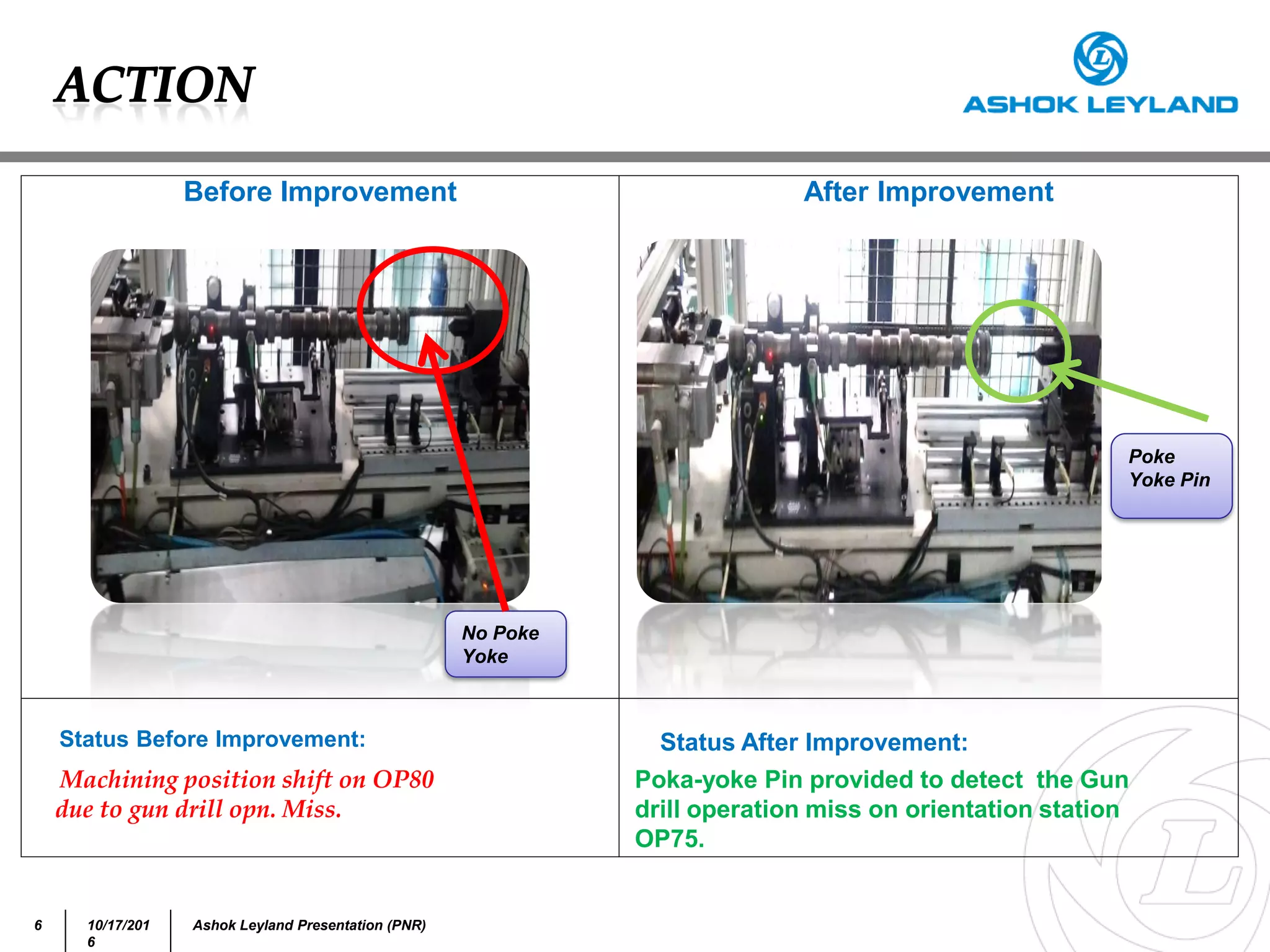

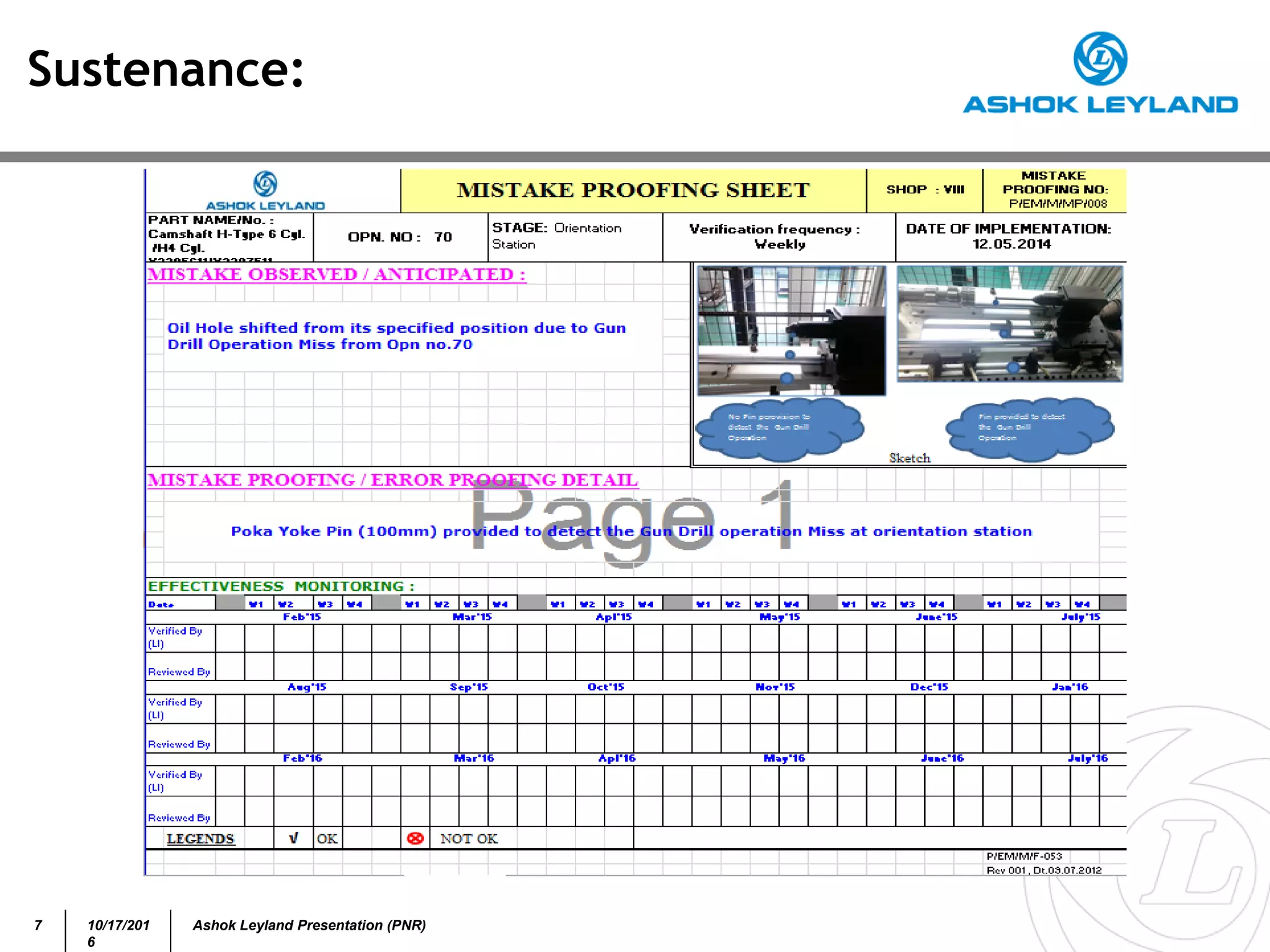

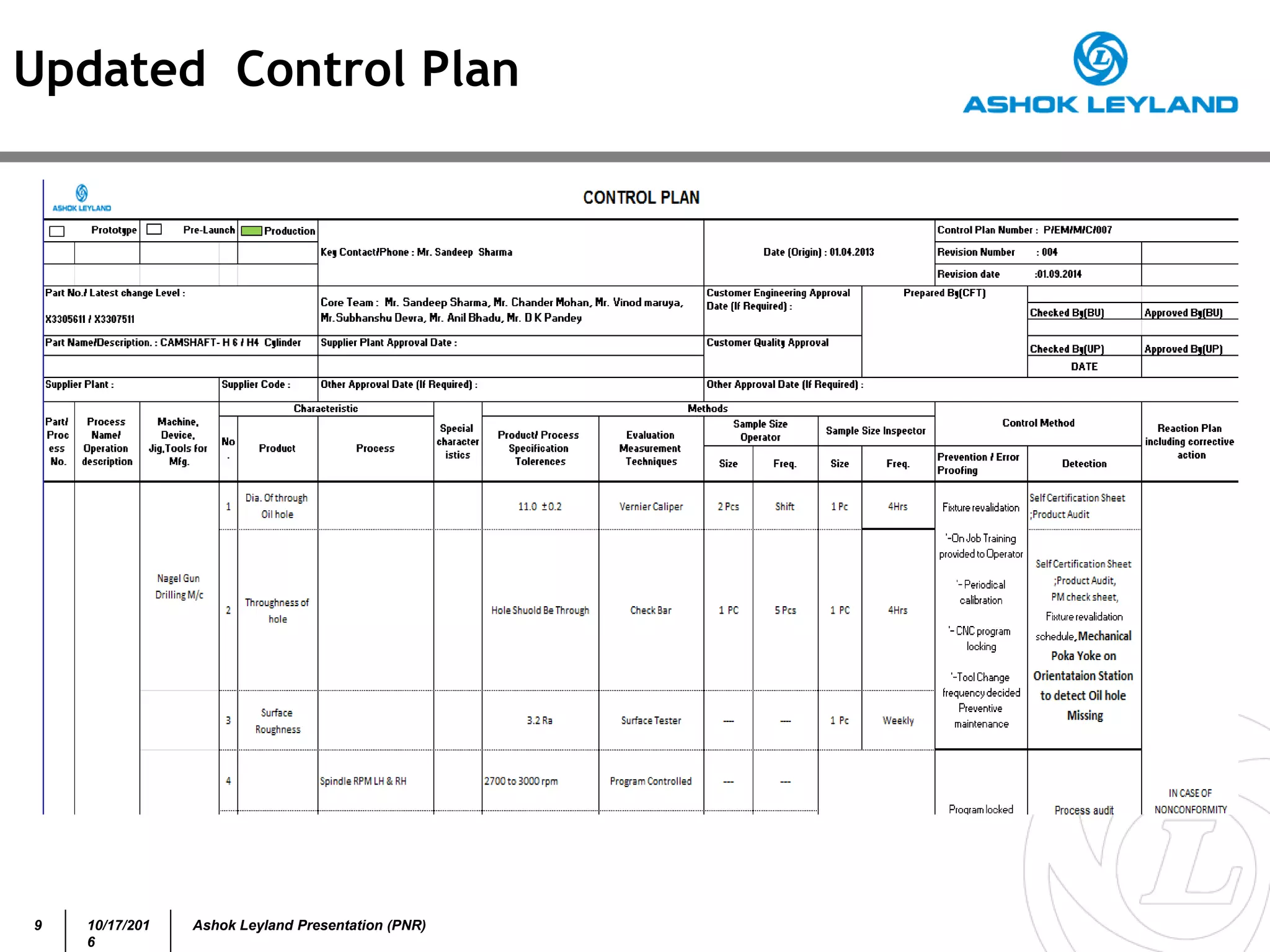

1) Implementing a poka-yoke (mistake-proofing device) in the form of a mechanical pin at Operation 75 to detect if the previous cross oil hole operation was missed.

2) Analyzing the manufacturing process and root causing the problem to human error where the operator was advancing the part without inspecting for completion of the cross oil hole operation.

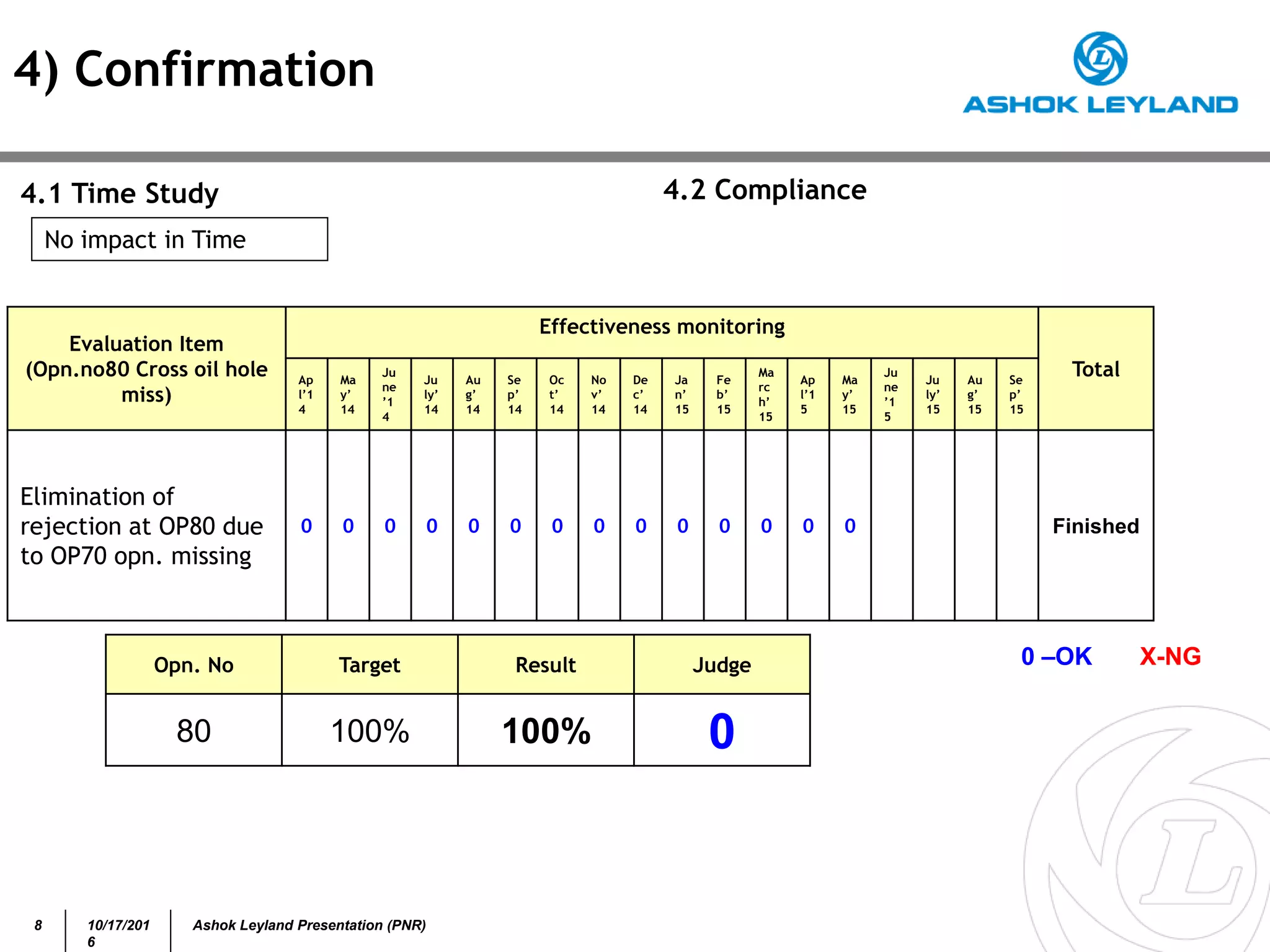

3) Monitoring the effectiveness of the poka-yoke over time which showed that rejections at Operation 80 due to the missing cross oil hole operation were eliminated.