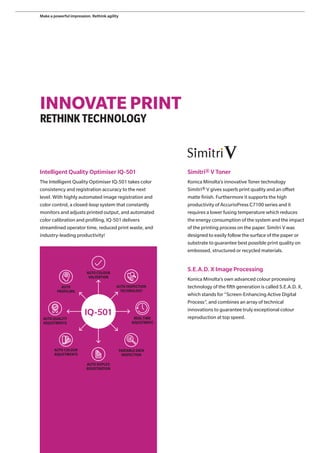

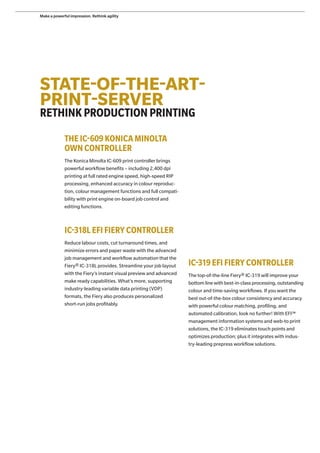

The AccurioPress C7100 and C7090 series by Konica Minolta focuses on enhancing print production through intelligent automation, superior color quality, and extensive media handling capabilities. With features like the Intelligent Quality Optimizer, advanced finishing options, and eco-friendly Simitri V toner, these printers are designed for high efficiency and reliability in meeting diverse printing needs. These models aim to empower businesses to expand their offerings while minimizing waste and turnaround times.