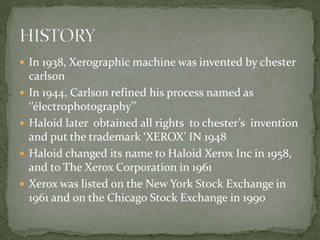

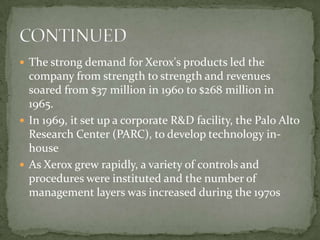

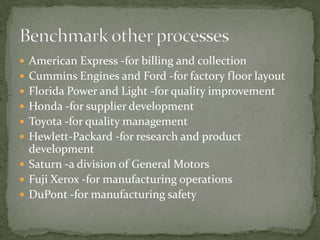

Xerox was founded in 1938 and grew rapidly in the 1960s due to strong demand for its photocopier products. However, by the 1970s it faced increasing competition. In the 1980s, Xerox introduced benchmarking and total quality management programs to improve processes like supplier management, inventory control, and customer satisfaction. These initiatives helped Xerox reduce costs and reclaim market share, winning several quality awards. Today, Xerox remains the global leader in managed print services.