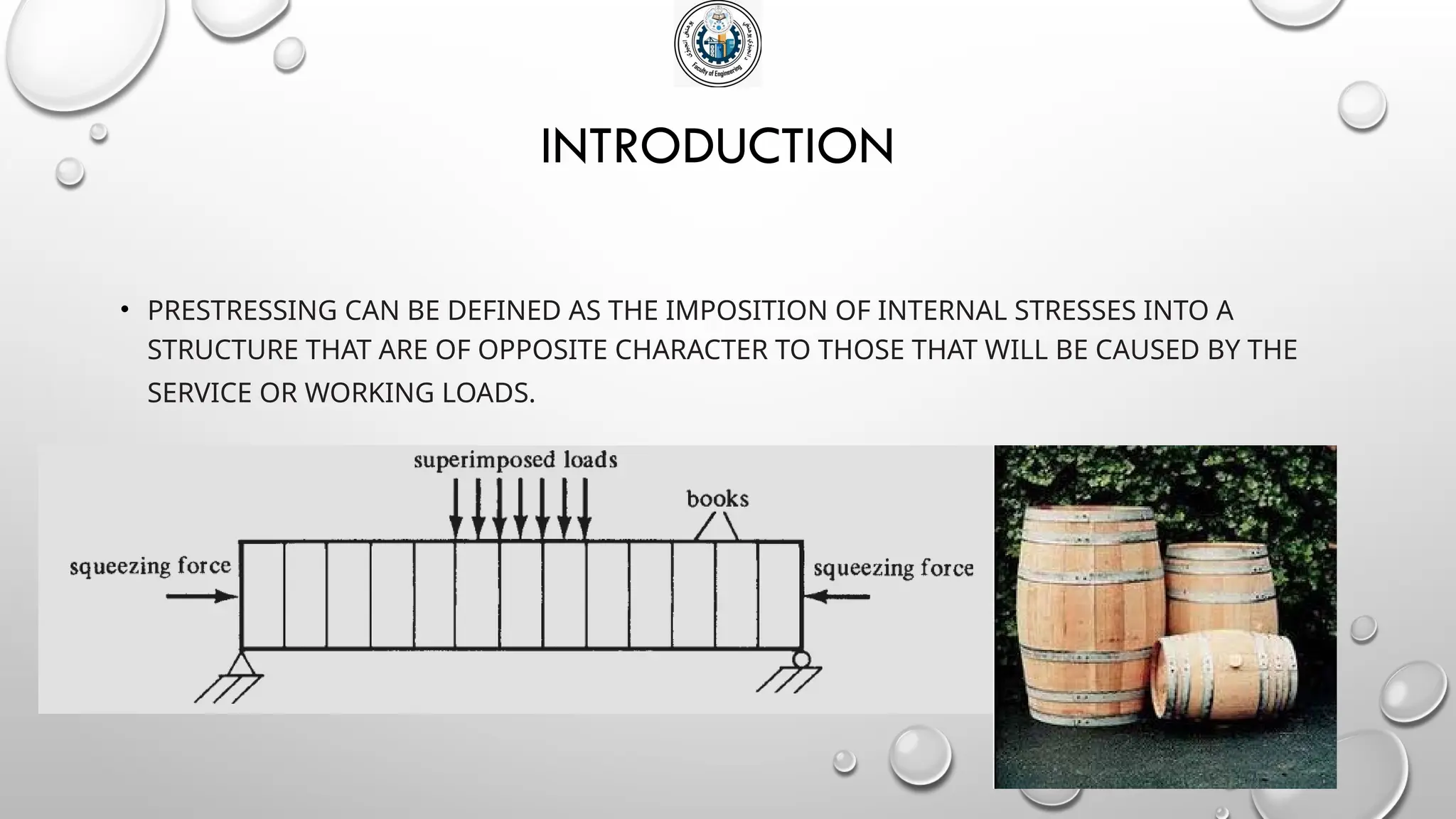

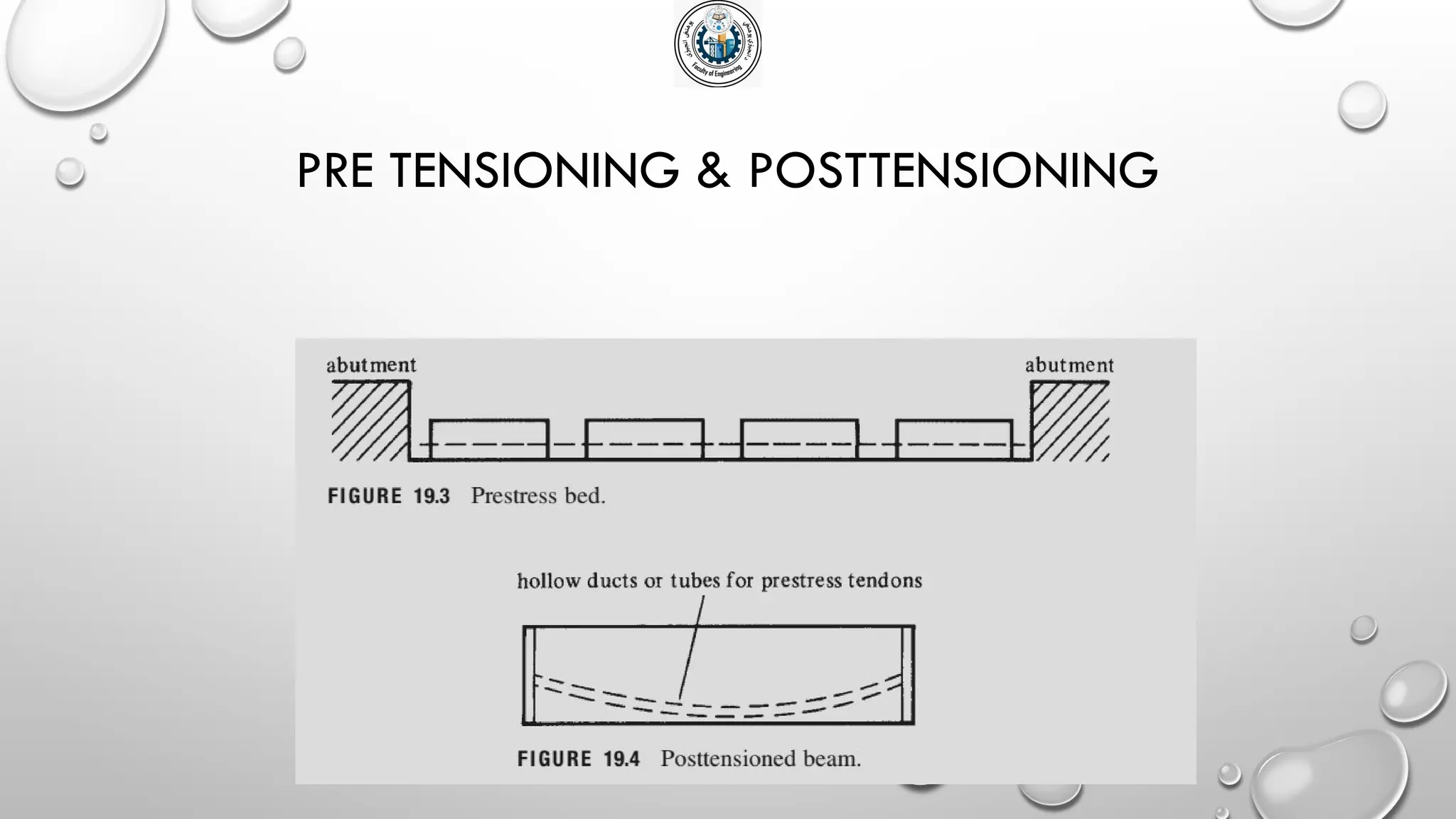

The document discusses prestressed concrete, highlighting its definition, procedures, and the advantages and disadvantages of using this technique. Advantages include reduced size and maintenance, crack-free performance, and increased resistance to loads, while disadvantages involve higher costs and complexity in manufacturing. It also covers the materials used, stressing the importance of high-strength steel and concrete in achieving the desired performance in prestressed concrete structures.