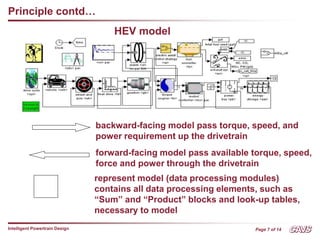

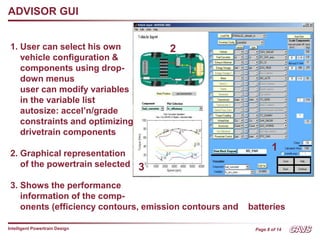

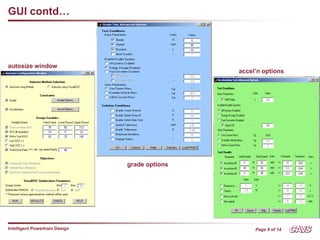

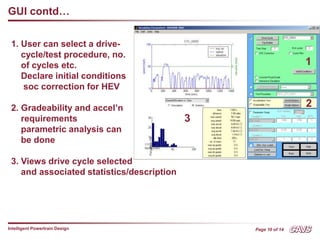

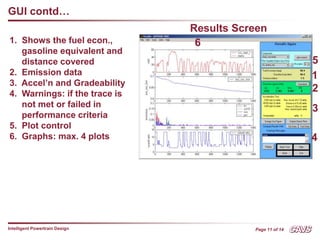

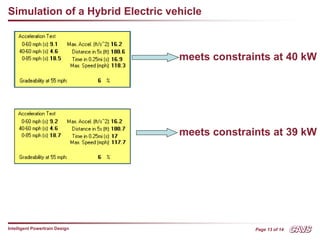

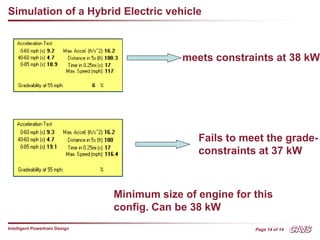

This document outlines the use of ADVISOR simulation software for modeling hybrid and electric vehicle powertrains. It discusses the need for simulation tools in vehicle design given the complexity of configurations and optimization parameters. The document then describes the key features of ADVISOR, including its graphical user interface, component models, and ability to simulate conventional, electric, and hybrid vehicles. An example application of ADVISOR to simulate a parallel hybrid vehicle and optimize engine size is also presented. Limitations of the tool for detailed dynamics modeling are noted.