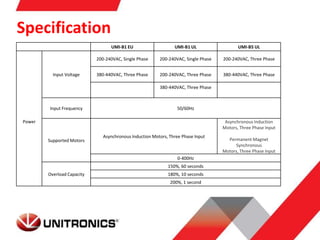

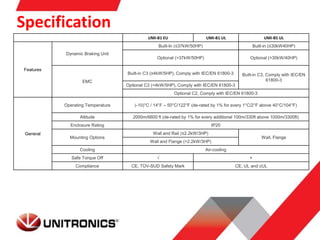

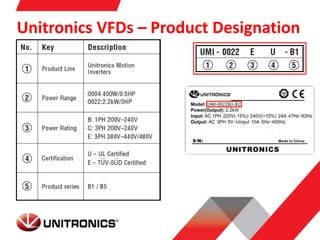

This document introduces Unitronics' new line of Variable Frequency Drives (VFDs) for controlling motor speed in various applications like printing, packaging, and more. It provides specifications for three Unitronics VFD models ranging from 0.4-110kW in power capacity. Unitronics VFDs offer features like sensorless vector control, built-in EMC filters, Modbus RTU communication, and safe torque off. They can be integrated with Unitronics PLCs and HMIs for a complete automation solution with unified programming software.