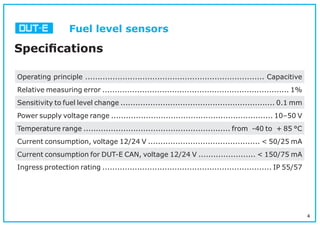

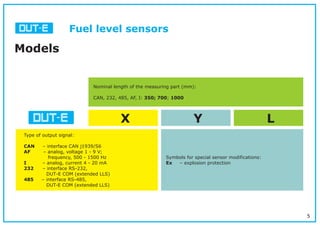

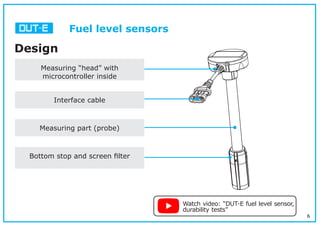

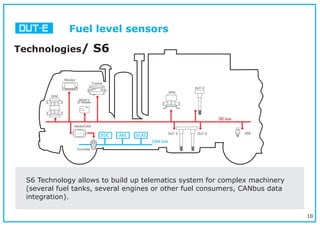

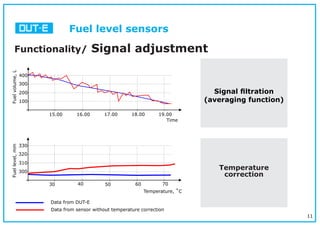

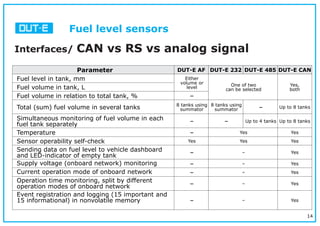

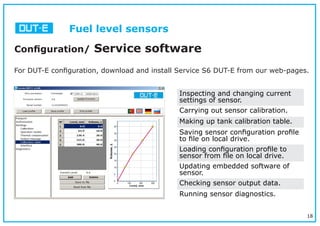

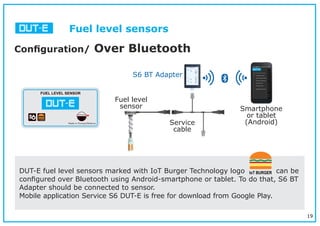

The document outlines the design, application, and specifications of fuel level sensors developed by Technoton, including features like capacitive measurement, varying lengths, multiple signal output options, and IoT capabilities. It highlights the sensors' effectiveness in monitoring fuel levels, detecting theft, and optimizing fuel consumption across various applications such as trucks and construction machinery. The sensors are adaptable to different fuel tank shapes and sizes, with comprehensive support for configuration and diagnostics.