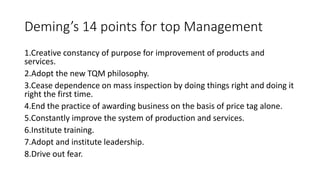

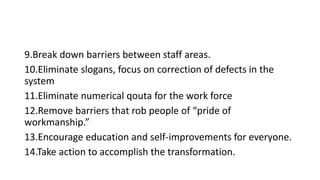

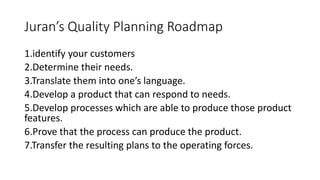

This document summarizes the evolution of several management theories from scientific management to total quality management. It describes Frederick Taylor's scientific management principles which aimed to improve worker productivity. Henri Fayol's general administrative theory focused on managerial functions and good practices. Max Weber contributed the idea of bureaucracy and organizational authority structures. Total quality management, introduced by Deming and Juran in the 1950s, emphasized customer satisfaction and doing things right the first time. It outlines Deming's 14 points and Juran's quality planning roadmap for implementing total quality management.