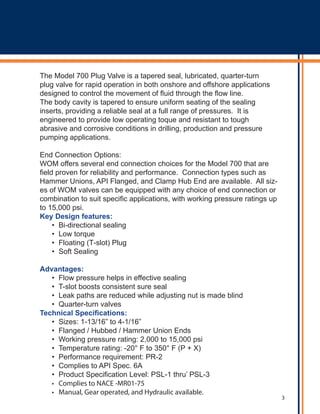

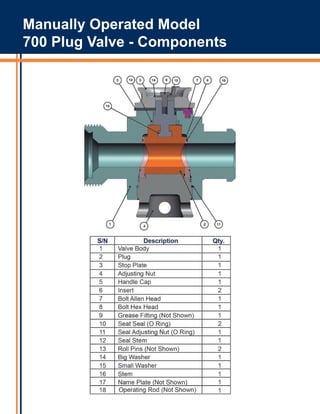

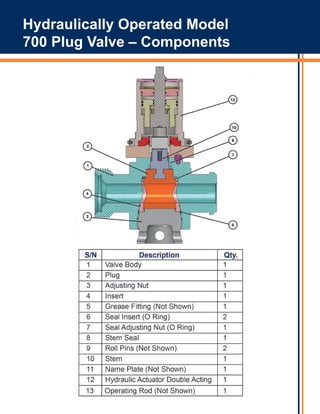

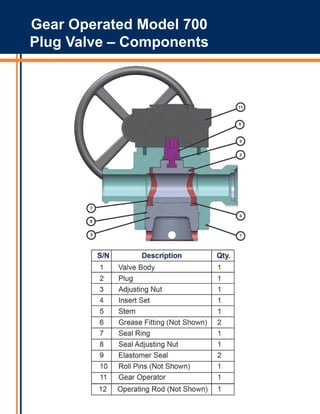

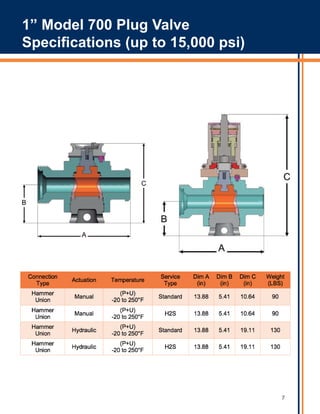

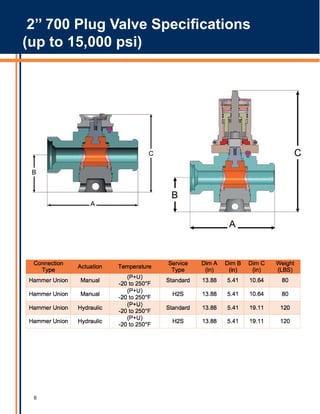

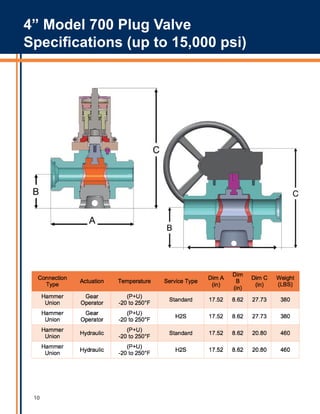

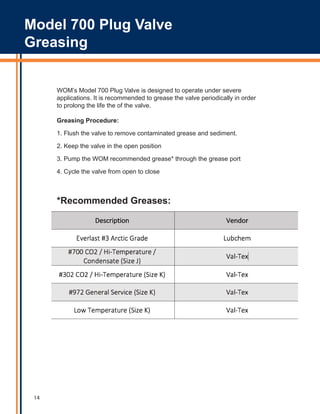

The document describes WOM's Model 700 plug valve, which is a tapered seal, lubricated, quarter-turn plug valve designed for rapid operation in onshore and offshore applications to control fluid flow. It has key features like bi-directional sealing and a floating plug, advantages like effective sealing from flow pressure and consistent sealing from the T-slot design. The document provides specifications on sizes, pressure ratings, temperature ratings, end connection options, and available manual, gear, and hydraulic actuation methods. It also includes exploded views and greasing procedures.