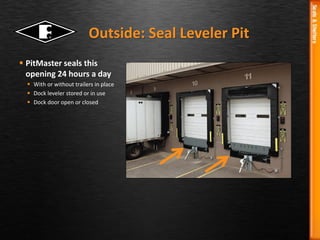

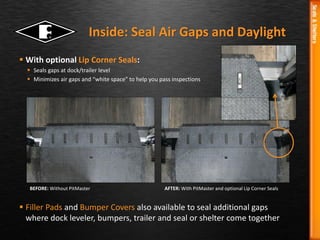

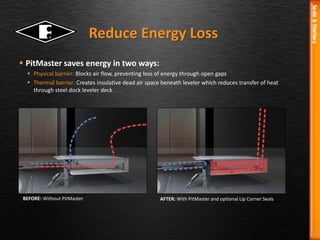

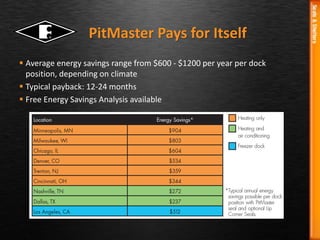

The document promotes the Pitmaster under-leveler seal, designed to seal loading dock openings and enhance energy efficiency by blocking air flow. It highlights the benefits of reducing contaminants and maintaining cleanliness at docks, alongside offering potential energy savings of $600 to $1200 annually. The seal is easy to install and maintain, with a money-back satisfaction guarantee.