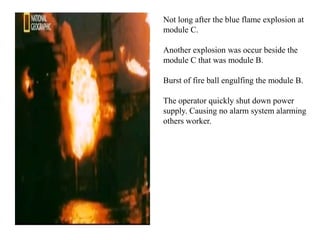

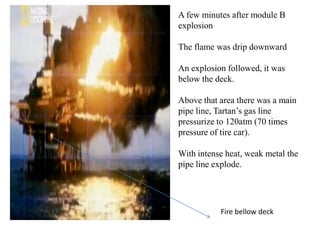

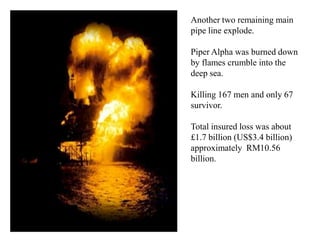

Piper Alpha was an oil production platform located in the North Sea that produced natural gas, LPG, and crude oil. On July 6, 1988, an explosion occurred on the platform due to a leak from a safety valve that was under maintenance but mistakenly connected to a pump that was put into use. This caused a chain reaction of explosions and fire that ultimately destroyed the platform, killing 167 workers. The disaster was caused by poor documentation and separation of paperwork regarding maintenance and safety procedures for pumps and valves. In response, the oil industry implemented new safety measures, permit systems, and formal assessments.