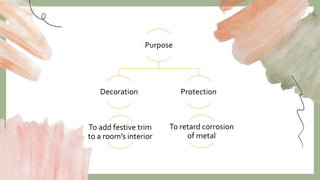

The document discusses paints and their components and manufacturing process. It provides details on:

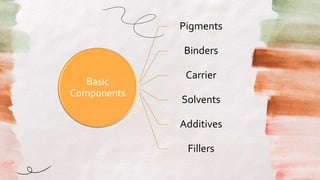

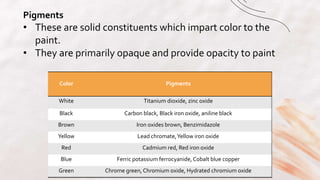

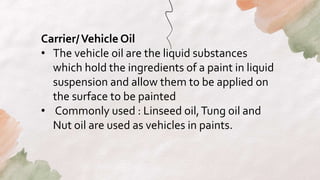

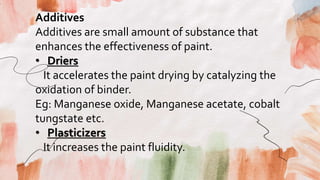

- The basic components of paint including pigments, binders, carriers, solvents, and additives. Pigments provide color while binders act as adhesives. Carriers hold the ingredients in liquid suspension.

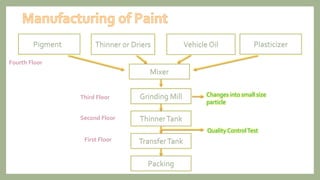

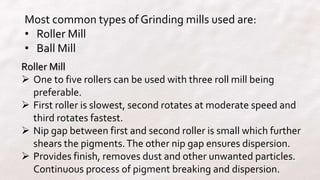

- The manufacturing process which involves mixing components, grinding them into small particles using roller or ball mills, adding solvents, quality control testing, and packing.

- Requirements for good paints including being opaque, having good covering and hiding power, being chemically inert, weather resistant, washable, and anti-corrosive.