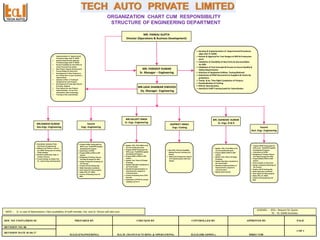

This document outlines the organizational structure and responsibilities of the Engineering Department. Mr. Pankaj Gupta is the Director of Operations and Business Development. The department is divided into several teams focused on new product development, current production processes, costing, and R&D. Key responsibilities include implementing quality procedures, developing new products, designing tooling and fixtures, updating documentation, and submitting production part approval processes.