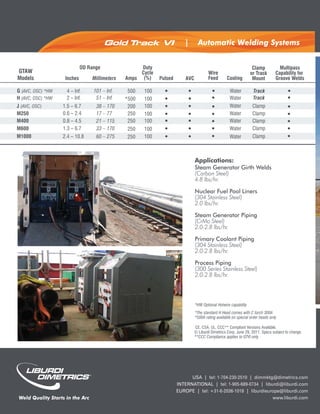

This document describes Liburdi's Gold Track VI automatic welding systems. It summarizes several weld head models - G, H, J, and M-series - that are suited for different pipe sizes and configurations. It also outlines the GTVI and P300 power sources that can provide up to 500 amps of power. The systems are designed for automatic welding of pipes and assemblies in applications like steam generators, nuclear components, and process piping using GTAW techniques.