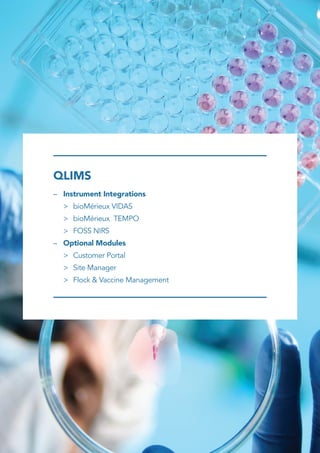

Baiada is a poultry company that processes over 250,000 samples each year to ensure product safety and consistency. Their previous database was becoming insufficient due to increasing complexity and volume. They implemented OnQ's QLIMS software, which provides customization, robust traceability, and the ability to integrate various instruments and modules. The implementation was quick and the OnQ team provided helpful support. QLIMS has saved significant time by automating processes like direct sample result integration and online sample submission, allowing Baiada to reallocate 1.5 FTEs to more important roles. Baiada values their ongoing partnership with OnQ to continue evolving the system.