This thesis presents the design, construction, control, and analysis of a linear input Delta robot. The robot was designed and built to improve upon previous Delta robot designs for 3D printing applications. A novel method of controlling the robot using 5th order polynomial trajectories was developed to prevent jerk spikes that occur with traditional control methods. Experimental analysis was performed to characterize the robot's velocity, accuracy, and motion capabilities both theoretically and experimentally. The results demonstrate the robot functions as intended and the control method successfully eliminates jerk spikes.

![7

LIST OF FIGURES

Page

Figure 1: Clavel’s Delta Robot [8].................................................................................... 12

Figure 2: Linear Input Delta Robot [6]............................................................................. 13

Figure 3: Fanuc Robotic Arm [9]...................................................................................... 14

Figure 4: Traditional Cartesian 3D Printer ....................................................................... 15

Figure 5: Serial and Parallel Robot Comparison [3]......................................................... 16

Figure 6: Trapezoidal Velocity Profile [12]...................................................................... 17

Figure 7: 3rd

Order Polynomial Trajectory Profile [10].................................................... 18

Figure 8: Delta Robot Information ................................................................................... 21

Figure 9: A- Deltamaker 3D Printer[40] B- ORION 3D Printer[23] C- Kossel Mini 3D

Printer [24]........................................................................................................................ 22

Figure 10: A- Deltaprintr 3D Printer [25] B- Fanuc M-1iA Delta Robot [26]................. 22

Figure 11: Final Robot Design.......................................................................................... 24

Figure 12: Motions Executable by Robot. ........................................................................ 26

Figure 13: Timing Belt Driving Linear Motion Along Hardened Rods ........................... 28

Figure 14: NEMA 17 Stepper Motor................................................................................ 28

Figure 15: Two Parallel Links Connecting Each Carriage to End Effector ..................... 28

Figure 16: Deltamaker 3D printer (Hexagonal Frame) [40]............................................. 29

Figure 17: Top View of Robot, Showing the Hexagonal Shape of the Frame. ................ 30

Figure 18: A- Deltaprintr Linear Inputs Riding Directly on Vertical Supports [25] B-

Rod End Supports used to Secure Hardened Rods ........................................................... 31

Figure 19: A- Plexiglas Reinforcements Used to Stiffen Frame B- Electronic Hardware

Mounted to Plexiglas Sheet .............................................................................................. 32

Figure 20: A- Wing Nut Used to Adjust Build Surface Atop 3D Printed Mount B- ¾”

Oak Plywood Sheet and 12”x12” Borosilicate Glass Supported by Rubber Bumpers..... 33

Figure 21: Plywood Support Used to Force Top of Robot to Retain Hexagonal Shape .. 33

Figure 22: Obtuse 3D Printed Support Used to Connect Hexagonal Frame .................... 34

Figure 23: 3D Printed Fitting............................................................................................ 35](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-7-2048.jpg)

![8

Figure 24: Steel Fitting ..................................................................................................... 35

Figure 25: Mass and Cost Comparison of 3D Printed (PLA) and Machined Metal 90°

Fittings (McMaster Carr).................................................................................................. 35

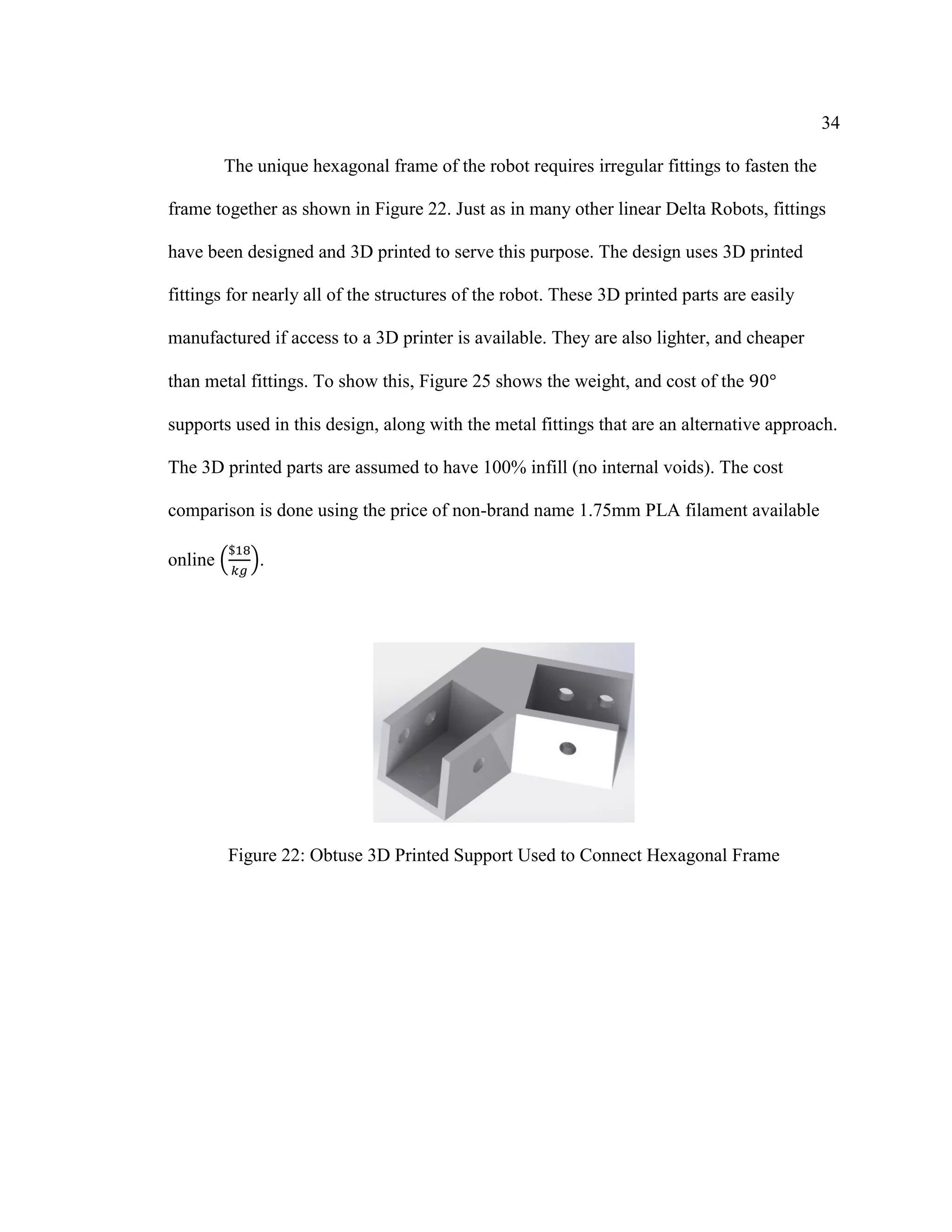

Figure 26: A- Model of Motor/Encoder Coupling B- 3D Printed Fixture Coupling

Encoder to Motor Shaft..................................................................................................... 36

Figure 27: A- Rendered Model of 3D Printed Robot Carriage B- Rendered Model of 3D

Printed End Effector ......................................................................................................... 36

Figure 28: 3D Printed Robot Carriage with Ball Joints.................................................... 37

Figure 29: A- 3D Printed Universal Joints [28] B- Magnetic Ball Joints [29]................. 37

Figure 30: Traxxas Rod End Ball Joints........................................................................... 38

Figure 31: A- Restrictive Orientation of Rod End Ball Joints [30] B- New Orientation of

Rod End Ball Joints .......................................................................................................... 39

Figure 32: A- Joint Limitation of End Effector (Side View) B- Joint Limitation of

Carriage (Top View)......................................................................................................... 39

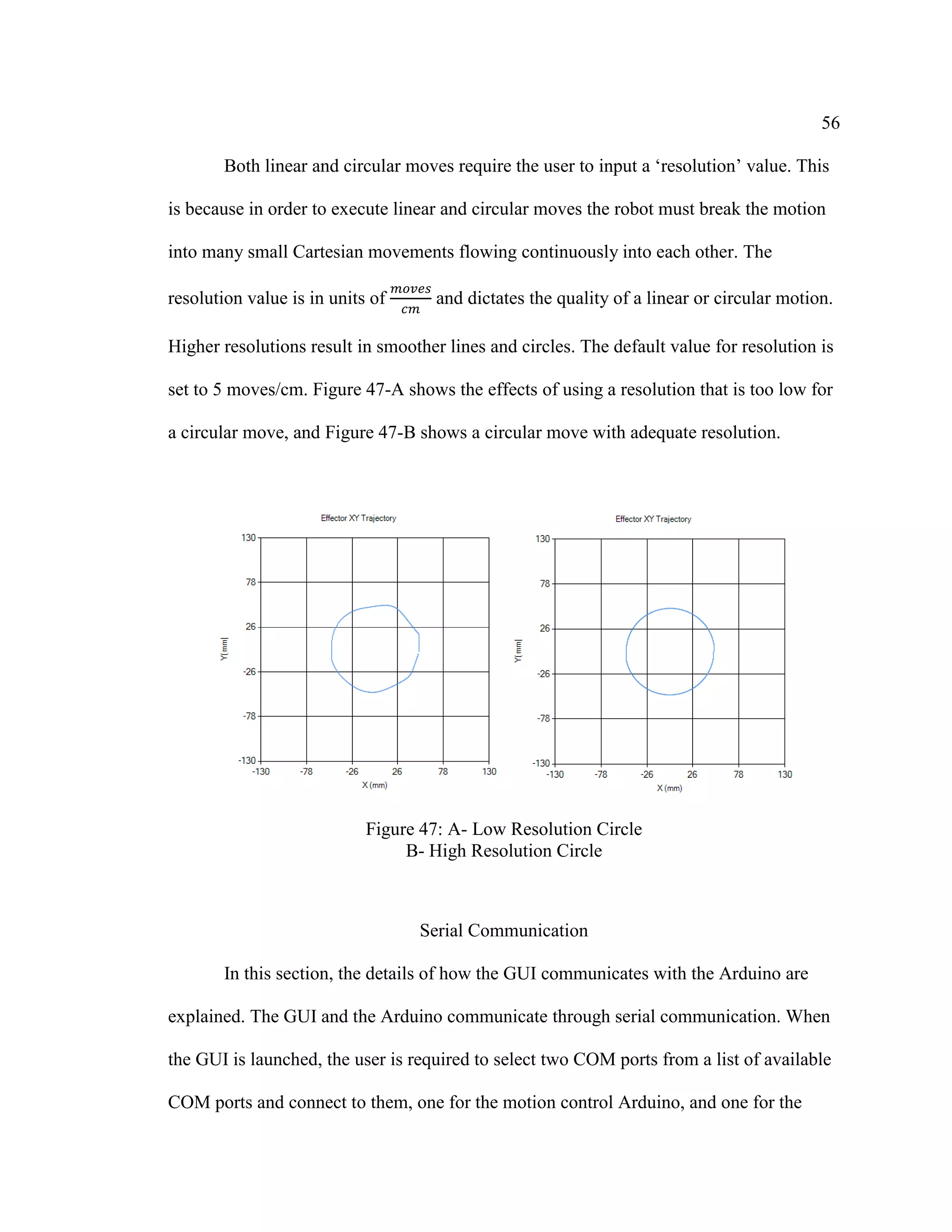

Figure 33: A- Joint Limit of End Effector (Top View) B- Joint Limit of Carriage (Side

View)................................................................................................................................. 40

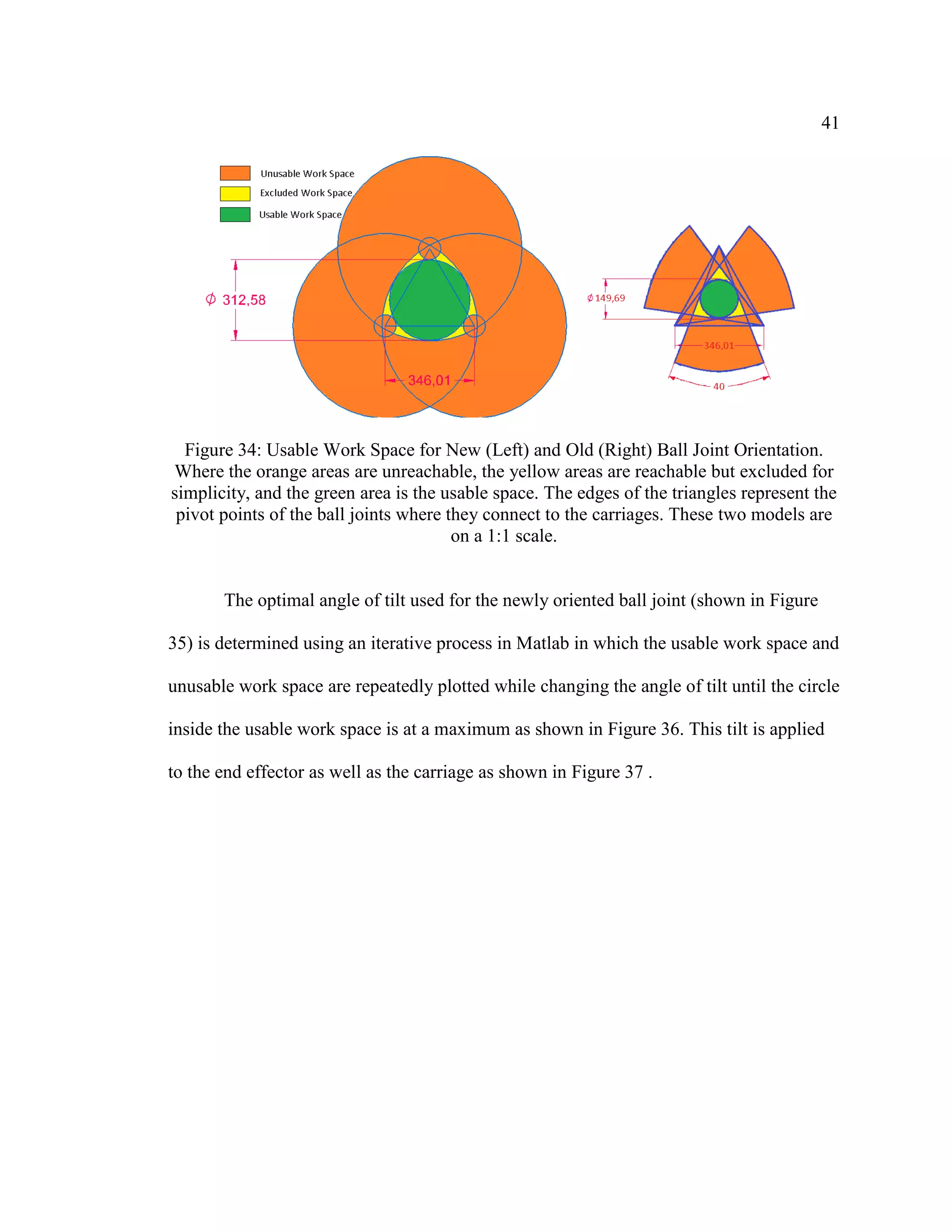

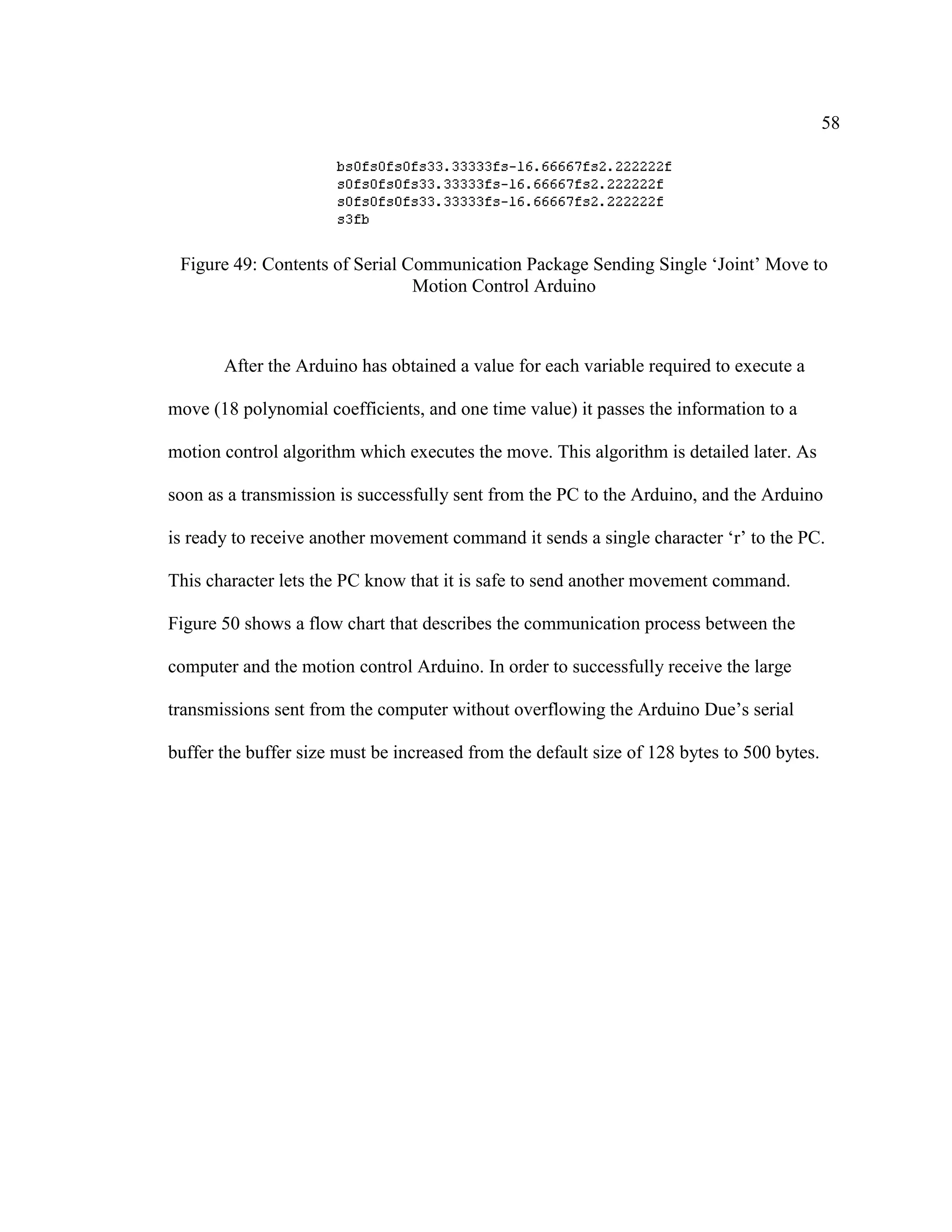

Figure 34: Usable Work Space for New (Left) and Old (Right) Ball Joint Orientation... 41

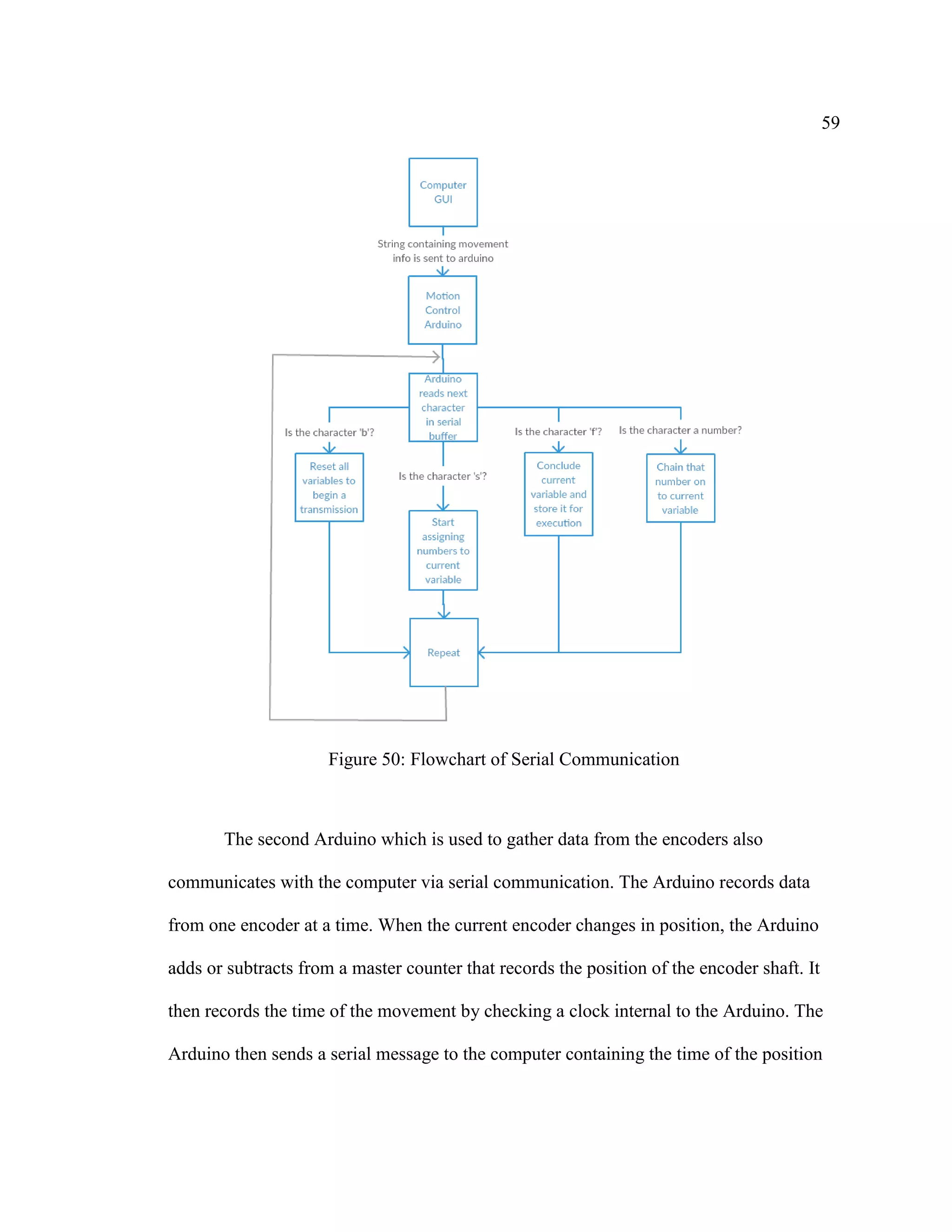

Figure 35: Optimal Angle of Tilt for New Ball Joint Orientation (60°)........................... 42

Figure 36: Matlab Plot Used to Iteratively Determine the Optimal Ball Joint Tilt to

Maximize Usable Work Area. .......................................................................................... 42

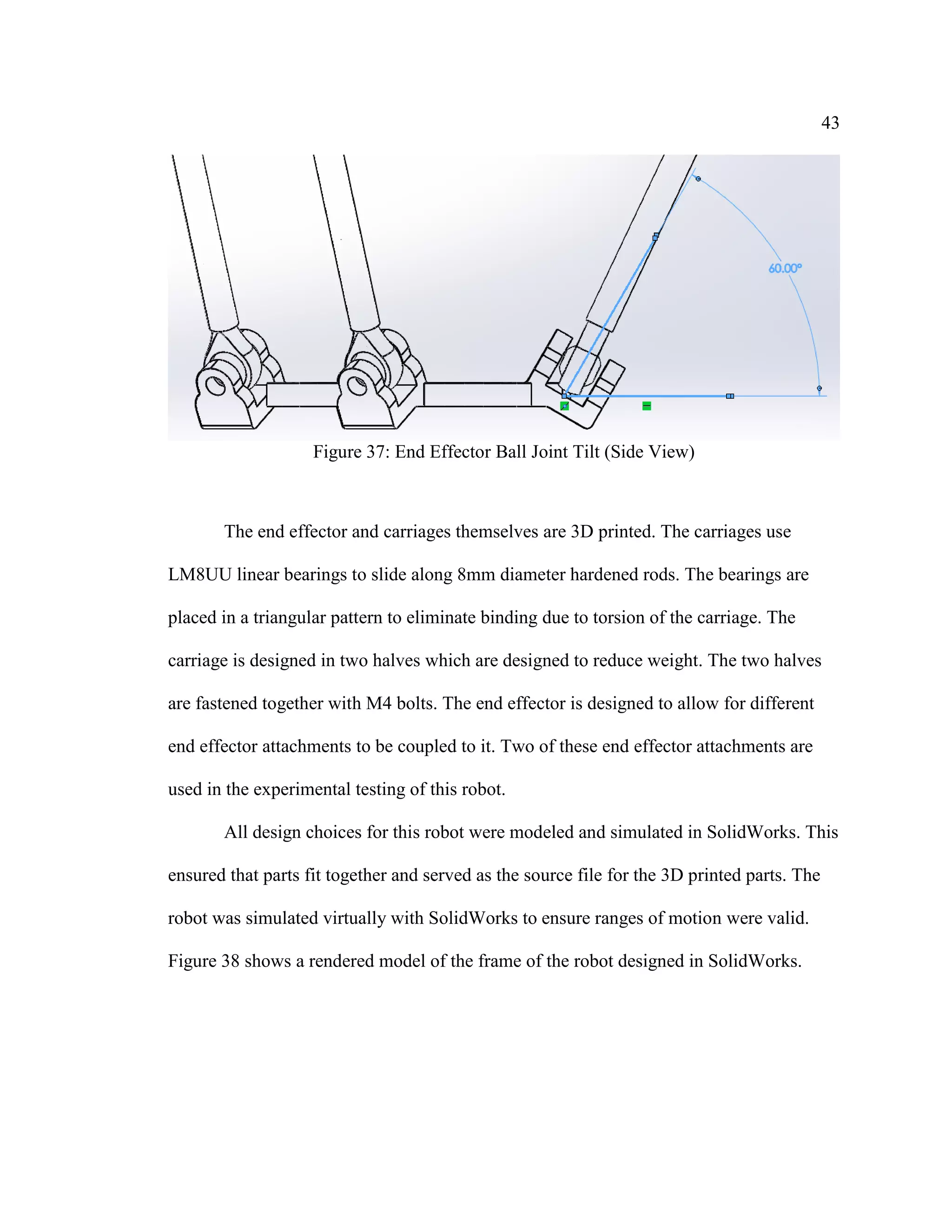

Figure 37: End Effector Ball Joint Tilt (Side View)......................................................... 43

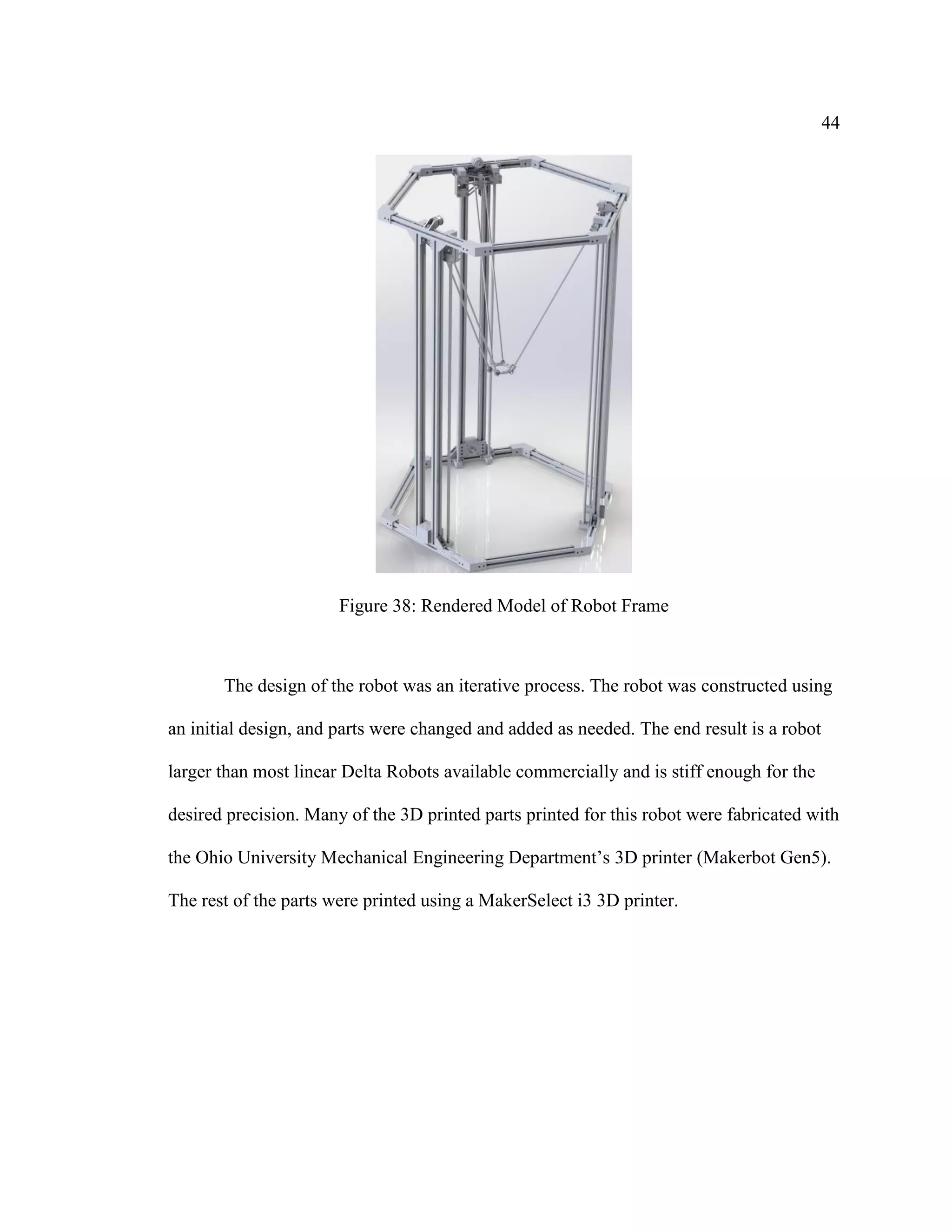

Figure 38: Rendered Model of Robot Frame.................................................................... 44

Figure 39: Pololu A4988 Stepper Motor Driver [32] ....................................................... 46

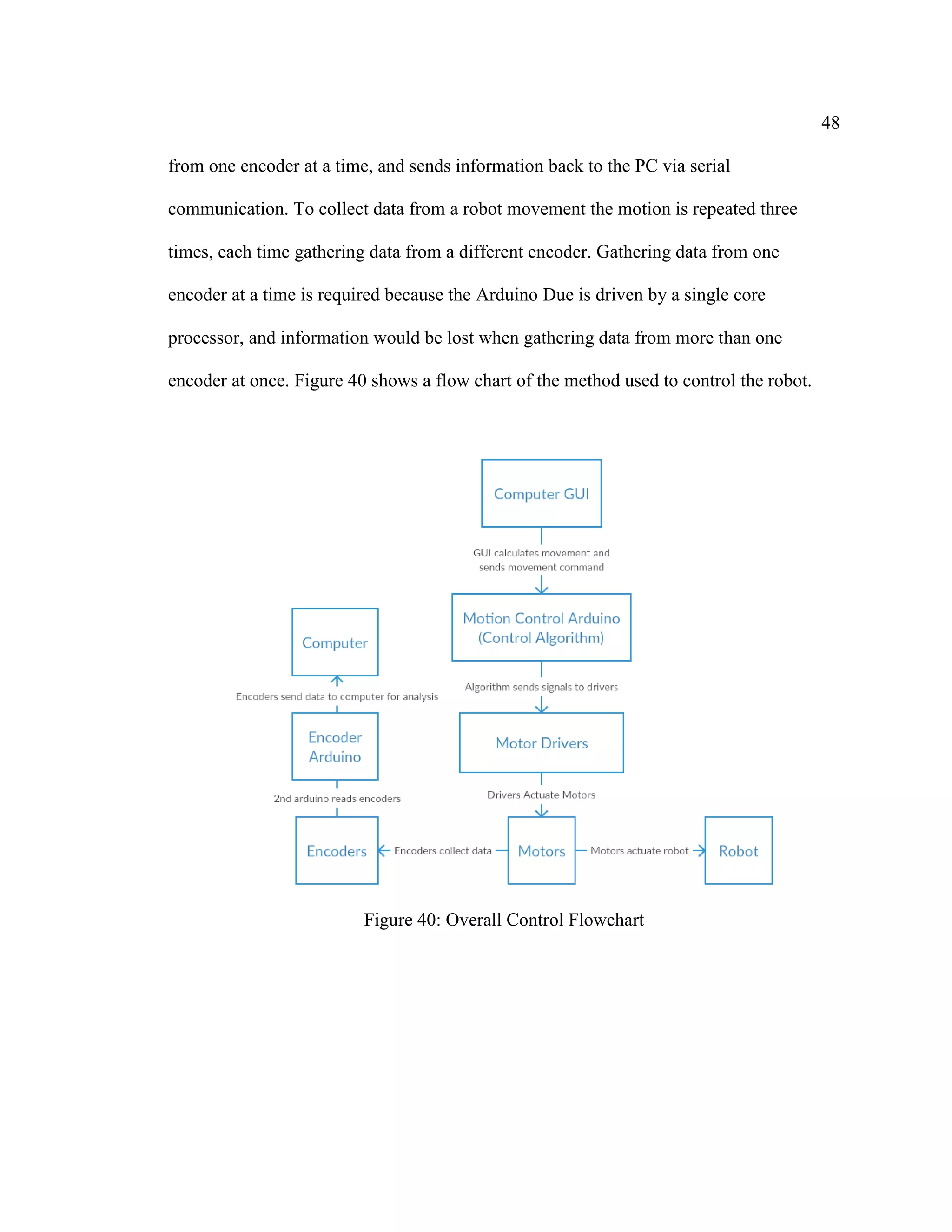

Figure 40: Overall Control Flowchart............................................................................... 48

Figure 41: 3D View of Linear Delta Robot Coefficients [5]............................................ 50

Figure 42: A- Top View of Robot Frame [5] B- Top View of Robot End Effector [5] ... 50

Figure 43: Essential Variables used in linear Delta Robot IPK/FPK [5].......................... 52

Figure 44: Circular Check [36]......................................................................................... 52

Figure 45: Robot GUI Startup Page.................................................................................. 54

Figure 46: Linear/Circular GUI Interface......................................................................... 55](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-8-2048.jpg)

![11

CHAPTER 1- INTRODUCTION AND LITERATURE REVIEW

Robots are important in many industries. They perform tasks that are too

repetitive or dangerous for humans to do, and virtually never make mistakes unless there

is a problem with their programming or hardware. They excel in pick and place

operations, welding, and CNC operations. With minimum wage increasing, they are even

used to serve us our food [1]. There are many different types of robots specialized for

different tasks.

Recently, robots have found a place in households in the form of 3D printing.

These 3D printers allow an individual with minimal skills to fabricate nearly any object

using a 3D printing process called FDM or fused deposition modeling. This involves

depositing layers of melted plastic onto a building surface layer by layer. By tracing out

the two dimensional cross sections of a three dimensional object and layering them on top

of each other, nearly any 3D object can be created. Recent developments in this field

such as the low cost microprocessor has caused a rapid expansion of the popularity and

affordability of this technology. 3D printing has become a very powerful tool both in

households and in industry and performs certain niche tasks more effectively than any

other fabrication technique. For example, 99% of custom hearing aids are created using

3D printing [2]. Other examples include fabricating bone implants, custom shoe insoles,

and tissue/organs [2].](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-11-2048.jpg)

![12

There are many different types of robots used for 3D printing. However the focus

of this thesis will not involve 3D printing, but the robot and control methods required for

3D printing or any other robot operation. These same control methods are used in CNC

mills, lathes, laser cutters, and other robots. The type of robot studied in this thesis will be

the linear input Delta Robot.

Literature Review

The Delta Robot was invented by Reymond Clavel in 1985 [4], [35]. Shown in

Figure 1, the original Delta Robot has three rotational input axes. The three arms attach to

three lower arms that consist of two parallel rods each forming a parallelogram. This

parallelogram restricted the motion of the end effector to three translational degrees of

freedom. The Delta Robot was invented primarily as a pick and place machine to move

chocolates from a conveyor belt into their packaging [4].

Figure 1: Clavel’s Delta Robot [8]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-12-2048.jpg)

![13

Recently with the advent of 3D printing, the Delta Robot has been revisited. Its

design excels at this task because of its three translational degrees of freedom, and its

speed [5]. Hobbyists and engineers have developed many different designs for the Delta

Robot for 3D printing, most importantly using linear inputs driven by timing belts instead

of rotational inputs. Figure 2 demonstrates how the end effector of the linear input Delta

Robot moves with three translational degrees of freedom as a result of three linear inputs

driving carriages with two spherical or universal joints connecting two parallel rods to the

end effector. The linear input Delta Robot has become a common choice when

purchasing a 3D printer.

Figure 2: Linear Input Delta Robot [6]

Parallel vs Serial Robots

The Delta Robot belongs to a group called parallel robots [3]. Parallel robots use

multiple links attached to the end effector in order to move. In most cases, the motors

used to drive parallel robots are mounted to the stationary frame of the robot, and do not

move [3]. Parallel robots excel at pick and place operations where speed is important [3],](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-13-2048.jpg)

![14

[5], [7]. Just as the first Delta Robot was used to move chocolates from a conveyor belt to

their packaging [4], today’s parallel robots are used for similar tasks (pick and place

operations, and 3D printing).

Robots that are not parallel are known as serial robots. Serial robots have only one

link attached to the end effector, and often the motors are attached to moving parts of the

robot [3]. The traditional robotic arm is an example of a serial robot as shown in Figure 3.

Other serial robots include the traditional 3D printer which consists of a moving gantry

with two degrees of freedom and a build plate with one degree of freedom as shown in

Figure 4.

Figure 3: Fanuc Robotic Arm [9]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-14-2048.jpg)

![15

Figure 4: Traditional Cartesian 3D Printer

Serial robots have both strengths and weaknesses. They have a large and simple

workspace [3], they also have high dexterity often in the form of six degrees of freedom

[3]. This makes serial robots effective in manufacturing environments where a task needs

carried out in a relatively large work cell (cage where the robot is enclosed for safety).

However serial robots also have numerous disadvantages. Each motor must overcome the

weight and inertia of the motors downstream of it, this results in slow speeds and a low

payload/weight ratio [3]. Along with this the error associated with each link is

compounding, resulting in large error in the location of the end effector [3].

Parallel robots also have many advantages and disadvantages. Their biggest

disadvantage is a small and complex work space [3] , [5]. Because of this, they can only

be used when the task can be completed in a very small area. However the advantages

make parallel robots the optimal choice in many situations. Because their motors are

mounted to the frame of the robot, the weight and inertia of the moving parts is low. This

results in higher top speeds and accelerations [3], [4], [5]. Along with their speed](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-15-2048.jpg)

![16

capabilities, parallel robots have a high payload/weight ratio, this is a result of multiple

links sharing the load of the end effector [3], [5]. Lastly, parallel robots are accurate [3].

This is because unlike serial robots, the error associated with the end effector does not

compound, but averages. Along with this, several links support the end effector resulting

in less strain. A more complete comparison of the advantages and disadvantages of serial

and parallel robots is provided in Figure 5.

Figure 5: Serial and Parallel Robot Comparison [3]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-16-2048.jpg)

![17

Current Methods of Control

In order for a robot to complete a task, there must be a method of control used to

plan the motion of each actuator. This involves using the inverse pose kinematics to find

the initial and final angle of each motor shaft when given the (x, y, z) coordinates of the

end effector’s starting and ending point [10]. Each motor shaft must move from the initial

angle to the final angle in order for the end effector to reach the desired location [10].

The purpose of the control method is to dictate how the motor shafts will move

from their initial to their final angle in a smooth and timely manner. This is also referred

to the trajectory that each motor shaft follows. In motion control, trajectories are often in

the form of ‘trapezoidal velocity profiles’ [7], [11], [17]. This control method results in a

period of constant acceleration, followed by a period of constant speed, followed by a

period of constant deceleration as shown in Figure 6.

Figure 6: Trapezoidal Velocity Profile [12]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-17-2048.jpg)

![18

Another common trajectory generation method is through the use of 3rd

order

polynomials [10][13]. If four initial conditions are known (initial/final position/velocity),

the coefficients of a third degree polynomial can be derived which will act as the

trajectory for the motor shaft to follow from the initial to the final angle as shown in

Figure 7.

Figure 7: 3rd

Order Polynomial Trajectory Profile [10]

Both trapezoidal velocity and 3rd

order polynomial trajectory control are used

because of their simplicity and seemingly smooth motion. However both share one

disadvantage: the occurrence of infinite jerk spikes [10]. Jerk is defined as the rate of

change of acceleration. An infinite jerk spike is a result of a discontinuity of acceleration.](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-18-2048.jpg)

![19

This is problematic because similar to velocity discontinuities being a physical

impossibility, acceleration discontinuities are a physical impossibility which are avoided

if possible in many areas such as motion control and cam design [10][14].

Control methods involving infinite jerk spikes attempt to force a motor to

accomplish something that is physically impossible. In most cases this is acceptable. The

resulting motion appears to be smooth, and because of their simplicity it has been

adopted as the norm for 3D printers and many robots to follow trajectories that involve

infinite jerk spikes such as trapezoidal velocity profiles [21].

Ensuring that no infinite jerk spikes occur can be essential in many applications.

Elevators are one instance where infinite jerk spikes are important to prevent [15].

Quality elevators have the capability to accelerate smoothly enough that passengers do

not feel themselves moving [15]. Without this smooth motion, motion sickness could

occur.

There are many negative effects of motion control involving infinite jerk spikes.

Motors undergo unnecessary wear by being controlled to do something they cannot do

[10]. This also creates unwanted vibrations in the frame of the robot. Currently, the speed

of FDM 3D printing (fused deposition modeling) is limited by the extruder and the heat

transfer rates [16]. This is the most common type of 3D printing involving layering

melted plastic. However as technology improves, robot speed may become the limiting

factor. At high speeds, the disadvantages of infinite jerk spikes may become more

pronounced and a more advanced method of control may be needed to prevent poor print](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-19-2048.jpg)

![20

quality caused by excessive vibrations, along with poor stepper motor performance which

are especially sensitive to resonance, and require smooth speed ramp up [17], [18].

One solution to the problem of infinite jerk spikes is the 5th

order polynomial

trajectory [19], [37], [38], [39]. Trajectory control via 5th

order polynomials prevents

infinite jerk spikes by ensuring that the acceleration undergoes no discontinuities. A 5th

order polynomial can be calculated using six initial conditions (initial and final position,

velocity, and acceleration).

Current 3D Printer and Home CNC/Robot Control

The advent of the cheap microprocessor has spurred a sharp increase in the

amount of robots and mechatronics projects available to engineers and hobbyists. These

microprocessors such as the Arduino, and the Raspberry Pi (a fully functional computer)

can be obtained for under $20 and are very small. Low cost 3D printers, CNCs, and other

robots have adopted these microcontrollers as a norm for low cost control [20].

Nearly all hobbyist microcontrollers used to control robots contain firmware

containing some variation of a g-code interpreter called ‘Grbl’ [21]. Grbl is a highly

optimized program whose primary purpose is to convert g-code into movement signals

that a robot’s motors can execute [21]. Grbl can fit onto an Arduino Uno, and can be used

to control a 3D printer, CNC, or other robot when configured correctly. Grbl is an

efficient tool for control, but suffers from infinite jerk spikes as a result of trapezoidal

velocity profile trajectory generation.](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-20-2048.jpg)

![21

Industrial motor controllers are high cost and use powerful hardware to control

robots. Some use methods to prevent infinite jerk spikes such as s-curves to gradually

change acceleration [22]. These controllers are too expensive to justify using in

household robots and CNCs. This generates a need for an affordable method of

controlling motors with the low cost microcontrollers that are currently in use.

Current Delta Robots

There are several different Delta Robot models currently in circulation. Figure 8

shows information about many popular models. The robots shown in Figure 8 are

depicted in Figure 9 and Figure 10. It can be seen that most Delta Robots have a

mechanical accuracy of approximately .1mm. This sets a standard that will be the goal of

the robot designed in this thesis. Achieving a resolution on the order of magnitude of

.1mm will be considered a success due to the prototype nature of the designed robot.

Figure 8: Delta Robot Information

Build Area Footprint Height (in) Accuracy Speed (mm/s)

Mini Kossel 6" Ø, 8.2" height 12"x12" 25.5" .1mm 300

Orion Delta 6" Ø, 9" height 14"x14" 24" .05mm 300

Deltaprintr 7" Ø, 10" height 11"x11" 24" .1mm 200

Deltamaker 9.5" Ø, 10.2" height 16"x16" 27" .1mm 300

Fanuc M-1iA/.5 11" Ø, 4" height 20"x17" 24.75" .02mm 3000

Thesis Robot 12"Ø, 15" height 27"x27" 36" Studied Studied](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-21-2048.jpg)

![22

Figure 9: A- Deltamaker 3D Printer[40]

B- ORION 3D Printer[23]

C- Kossel Mini 3D Printer [24]

Figure 10: A- Deltaprintr 3D Printer [25]

B- Fanuc M-1iA Delta Robot [26]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-22-2048.jpg)

![25

Objectives and Problem Statement

Based on the information presented above, it is clear that as 3D printing speeds

increase, there is a need for a method of control for robots using low cost

microprocessors that does not produce infinite jerk spikes. It is also clear that the design

of linear Delta Robots has not yet been perfected, and has room for improvement. The

goal of this thesis is to design a linear Delta Robot with improvements over previous

designs, and exploring design choices not yet visited. These design choices will be

analyzed and the constructed robot will be tested to quantify its speed, and accuracy. The

robot will be controlled to produce motion following 5th

order polynomial trajectories to

prevent infinite jerk spikes.

Objective 1- Design and Construction of Linear Input Delta Robot

The most effective design choices of popular models will be incorporated into the

design of this new model of linear Delta Robot along with new design choices not yet

explored. The robot will be designed with low cost in mind, as one purpose of the thesis

is to use low cost hardware to achieve high quality performance.

Objective 2- Achieve Control via 5th

Order Polynomial Trajectories

The method of 5th

order polynomial trajectories given by Craig [19] will be used

to plan the motion of the robot to prevent infinite jerk spikes. The control method will

allow the robot to execute the types of motion described in Figure 12. These types of](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-25-2048.jpg)

![26

motion are required to execute g-code generated for the purpose of 3D printing or CNC

operation [21].

Motion Type User Input Description

Joint Initial, final joint angles

Each joint follows 5th

order

trajectory from point A to point B.

Nonlinear end effector motion.

Cartesian Initial, final (x, y, z)

Each joint follows 5th

order

trajectory from point A to point B.

Nonlinear end effector motion.

Linear Initial, final (x, y, z)

End effector follows straight line

from point A to point B.

Circular

Initial, final, and pivot point (x, y, z)

End effector follows specified arc

from point A to point B about the

pivot point.

Figure 12: Motions Executable by Robot.

Objective 3- Analyze Robot Experimentally and Theoretically

The theoretical accuracy of the robot is computed by compounding the error

associated with each component of the robot using error propagation formulations. This

error will be tested experimentally to quantify the actual accuracy of the robot. The

maximum speed of the robot will be quantified based on the control algorithms. Lastly,

the actual motion of the robot will be compared to the theoretical motion via optical

encoders coupled to the motor shafts. This data will be used to verify that the actual

motion of the robot matches the theoretical motion.](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-26-2048.jpg)

![29

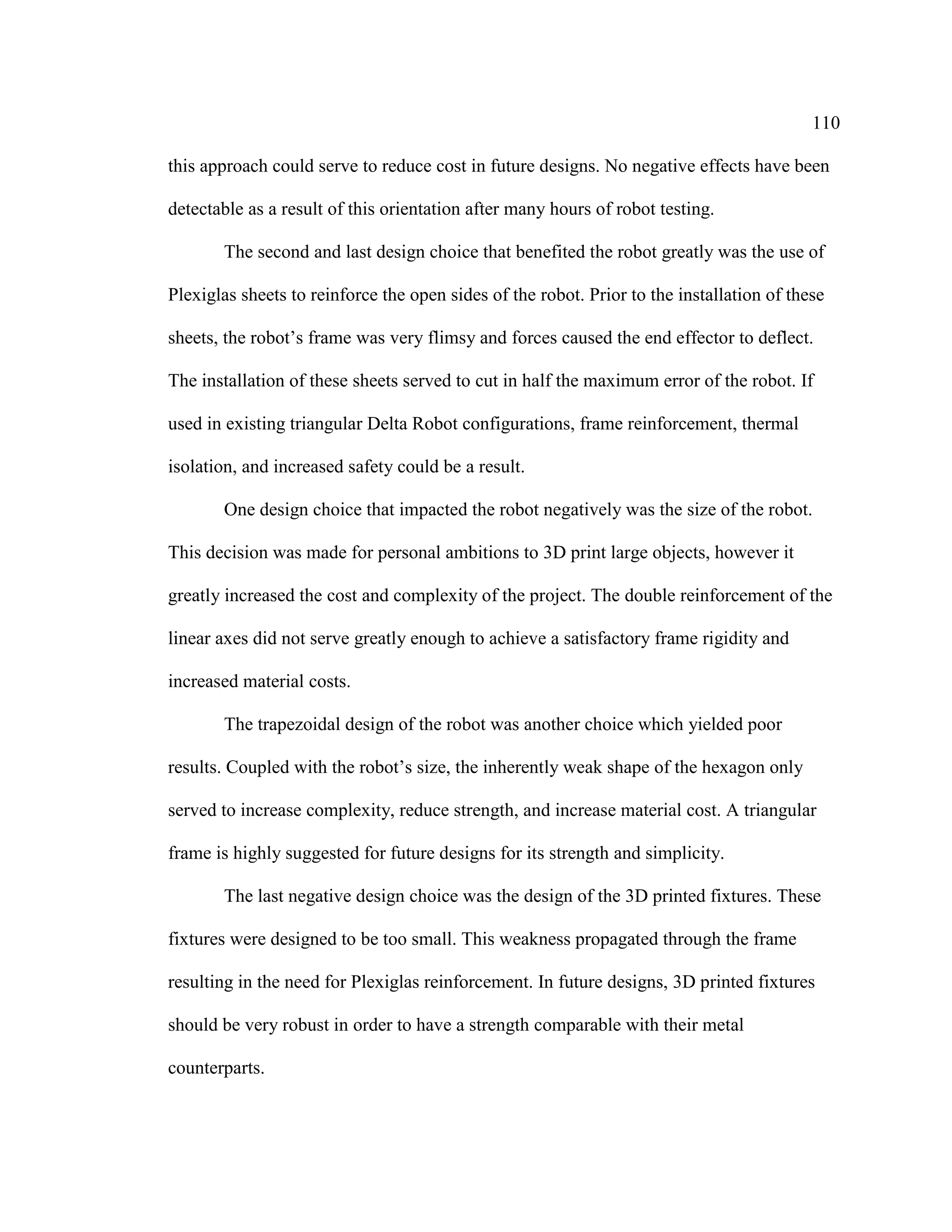

Unique Design Choices

Several design choices were made in the construction of this robot which are

uncommon or not seen at all in commercial linear Delta Robots. These design choices

were chosen with the goal of improving different aspects of the design. Some design

choices may unexpectedly result in poor results. This thesis will serve as a trial to show

the positive and negative effects of the design choices used.

The first design choice that deviates from commercial Delta Robots is a

hexagonal frame shown in Figure 17. This design choice is similar to that used in the

deltamaker robot shown in Figure 16. Most linear Delta Robots use a triangular frame to

increase stiffness and simplicity. A hexagonal frame allows for a large build plate to be

attached without overhang on the sides of the robot. The hexagonal frame works in

conjunction with the next unique design choice: double reinforced linear axes.

Figure 16: Deltamaker 3D Printer (Hexagonal Frame) [40]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-29-2048.jpg)

![31

Figure 18: A- Deltaprintr Linear Inputs Riding Directly on Vertical Supports [25]

B- Rod End Supports used to Secure Hardened Rods

The third unique design choice used in this robot is three Plexiglas walls (shown

in Figure 19) coupled to the three unsupported hexagonal sides of the robot. These walls

serve four purposes: to act as a partial safety barrier between the user and the robot in the

case of dangerous operations such as laser cutting and milling, to serve as a partial

enclosure for 3D printing where air flow from the environment can cause adverse effects

on the quality of a 3D printed part, to act as an electrically insulated surface on which to

mount the electronics (shown in Figure 19), and most importantly to add stiffness to the

frame. The three Plexiglas walls can be easily removed for full access to the central area](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-31-2048.jpg)

![37

Figure 28: 3D Printed Robot Carriage with Ball Joints

Commercial 3D printers use three types of joints to connect the end effector to the

carriages: 3D printed universal joints (Figure 29-A), magnetic ball joints (Figure 29-B),

and rod end ball joints (Figure 30). Rod end ball joints were chosen to use in this design

because of their low cost, and tight fit (no detectable error).

Figure 29: A- 3D Printed Universal Joints [28]

B- Magnetic Ball Joints [29]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-37-2048.jpg)

![39

Figure 31: A- Restrictive Orientation of Rod End Ball Joints [30]

B- New Orientation of Rod End Ball Joints

Figure 32: A- Joint Limitation of End Effector (Side View)

B- Joint Limitation of Carriage (Top View)](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-39-2048.jpg)

![45

Control of the Robot

Like most linear Delta Robots, NEMA 17 stepper motors are used as the primary

actuators. These motors are useful because of their open loop nature. Another quality that

makes stepper motors suitable for linear Delta Robots is their ability to produce large

torques at low speeds [31]. This is opposed to servo motors which can attain high speeds

but have low torques [31]. These servo motors require a gearing system to convert their

speed into torque, and require an optical encoder to provide positional feedback to form a

closed loop control system. This requires complicated control methods to accurately

control motion, along with powerful hardware to keep up with the calculations while also

reading each encoder. Because the Arduino and other low cost microcontrollers are an

important part of current household robots, powerful servo motors are uncommon due to

the Arduino’s inability to control them successfully due to lack of computational power.

Stepper motors however do not suffer from the disadvantages of servo motors.

They are simple to control. Because of their high torque at low speeds they can be used as

direct drive motors [31]. Direct drive motors do not require a gearing system in order to

actuate a system [31]. Stepper motors operate by modulating current through coils inside

the motor. The current flowing through these coils creates a magnetic field which turn a

permanent magnet inside the motor.

Each time the electric field is changed the motor takes one “step” forward. Most

NEMA 17 stepper motors have a resolution of 200 steps per revolution. Proper regulation

of the current through the motor coils can result in resolutions higher than 200 steps per

resolution, this process is called ‘microstepping’. Hobbyist stepper motor drivers such as](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-45-2048.jpg)

![46

the ‘Pololu a4988’ [32] shown in Figure 39 are an important tool for controlling stepper

motors. Pololu a4988 stepper motor drivers are used to control this robot’s motors.

Figure 39: Pololu A4988 Stepper Motor Driver [32]

Stepper motor drivers contain circuitry that regulates the current through stepper

motor coils automatically. Microstep resolution on the a4988 driver can be set as high as

3200 steps per revolution [32] (each step broken into 16 microsteps). All that is required

to drive a motor with a stepper motor driver like the a4988 is that it is supplied with a

digital signal for both step and direction. Setting the step pin to ‘high’ actuates the motor

forward or back one microstep depending on the state of the direction pin.

The a4988 stepper driver is a ‘chopping’ stepper motor driver. Chopping drivers

allow the user to set a current limit for the motor for safety, and allow the use of higher

voltages than the motor is rated for [32]. The current limiting protects both the driver and

the motor, and the use of higher voltages allows for higher step response speed, which

results in higher top speeds for motors [32]. Stepper motor drivers allow a robot to be

controlled with a low cost microcontroller such as an Arduino.

In this thesis, an Arduino Due is used for control of the robot in conjunction with

a PC. The Arduino Due has more computational power than other models because it is](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-46-2048.jpg)

![47

equipped with a 32 bit processor as opposed to an 8 bit processor [33]. This allows for

faster computations that allow a 5th

degree polynomial trajectory motion algorithm to be

possible. Along with a 32 bit processor, the clock speed of the Arduino Due is 84MHz,

up from 16MHz with other Arduinos [33]. This increase in speed and processing power

makes the Arduino Due the only Arduino model powerful enough to drive a robot at

useful speeds using 5th

order polynomial trajectories.

One other difference between the Due and other models is its use of 3.3V logic.

As a result of the Due operating with 3.3V logic, 5v signals such as the signals supplied

by the optical encoders must be reduced to safe levels using a voltage divider circuit. A

voltage divider circuit uses Kirchhoff’s voltage law in conjunction with two resistors to

reduce an input voltage to a lower level depending on the ratio between the two resistors

[34].

The control method used in this thesis will consist of several components. First, a

GUI (graphical user interface) WinForms application is created on a PC using C# and

Microsoft Visual Studio. The GUI allows the user controls the robot. The desired motion

is specified, and graphical data is generated describing the motion. The computer is

responsible for the kinematics of the robot and the trajectory generation. The computer

processes moves for the robot to execute and then sends information to the Arduino Due

through a serial communication link. The Arduino Due contains a motion control

algorithm that turns the computer’s data into robot motion.

A second Arduino Due is used to collect data from the three optical encoders

coupled to the motor shafts. The Arduino Due responsible for the encoders records data](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-47-2048.jpg)

![49

Linear Delta Robot Kinematics

One of the most important tools in controlling a robot is the Inverse and Forward

Pose Kinematic solutions. The Inverse Pose Kinematics is used to determine the angle of

each motor shaft for an end effector location in (x, y, z) coordinates. The Inverse Pose

Kinematics is especially important in the control of the robot because it is calculated for

every move made by the robot. The Inverse Pose Kinematics is required for control of

any robot. The Forward Pose Kinematics is used to determine the end effector location in

(x, y, z) coordinates if the angle of each motor shaft is known (J1, J2, J3).

There are many approaches possible to solve the forward and reverse pose

kinematics of a robot including numerical methods, symbolic methods, and graphical

methods [7]. R. Williams II. presents a solution to both the Forward and Inverse Pose

Kinematics for the linear Delta Robot [5]. Figure 41 and Figure 42 and equations (1)-(18)

detail the Forward and Inverse Pose Kinematics used in this thesis. Figure 43 shows a list

of the essential variables needed to perform kinematic analysis on this robot. The validity

of this approach is verified through the ‘circular check’, inserting the inverse pose

kinematics solutions into the forward pose kinematics and vice versa as shown in Figure

44. Because identical results are obtained, the solution is mathematically sound [5].](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-49-2048.jpg)

![50

Figure 41: 3D View of Linear Delta Robot Coefficients [5]

Figure 42: A- Top View of Robot Frame [5]

B- Top View of Robot End Effector [5]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-50-2048.jpg)

![52

𝑒 =

𝐿2

2

− 𝐿1

2

4𝑎

(18)

Name Meaning

𝑆 𝐵 P joints (𝐵𝑖) equilateral triangle side (mm)

𝑠 𝑝 Platform equilateral triangle side (mm)

𝐿𝑖 Leg length (mm)

𝑙 Lower legs parallelogram length (mm)

Figure 43: Essential Variables used in linear Delta Robot IPK/FPK [5]

Figure 44: Circular Check [36]

5th

Order Polynomial Trajectory Generation

This section details the methods used to calculate a 5th

order polynomial

trajectory. Trajectory control via 5th

order polynomials prevents infinite jerk spikes by

ensuring that the acceleration undergoes no discontinuities. As seen in equations (19)-(31)

a 5th

order polynomial can be calculated using six initial conditions, shown in equations

(23)-(25). Once a polynomial trajectory has been found, the velocity, acceleration, and

jerk can be calculated using equations (20), (21), and (22).

𝜃(𝑡) = 𝑎5 𝑡5

+ 𝑎4 𝑡4

+ 𝑎3 𝑡3

+ 𝑎2 𝑡2

+ 𝑎1 𝑡 + 𝑎0 (19)

𝜃̇( 𝑡) = 5𝑎5 𝑡4

+ 4𝑎4 𝑡3

+ 3𝑎3 𝑡2

+ 2𝑎2 𝑡 + 𝑎1 (20)](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-52-2048.jpg)

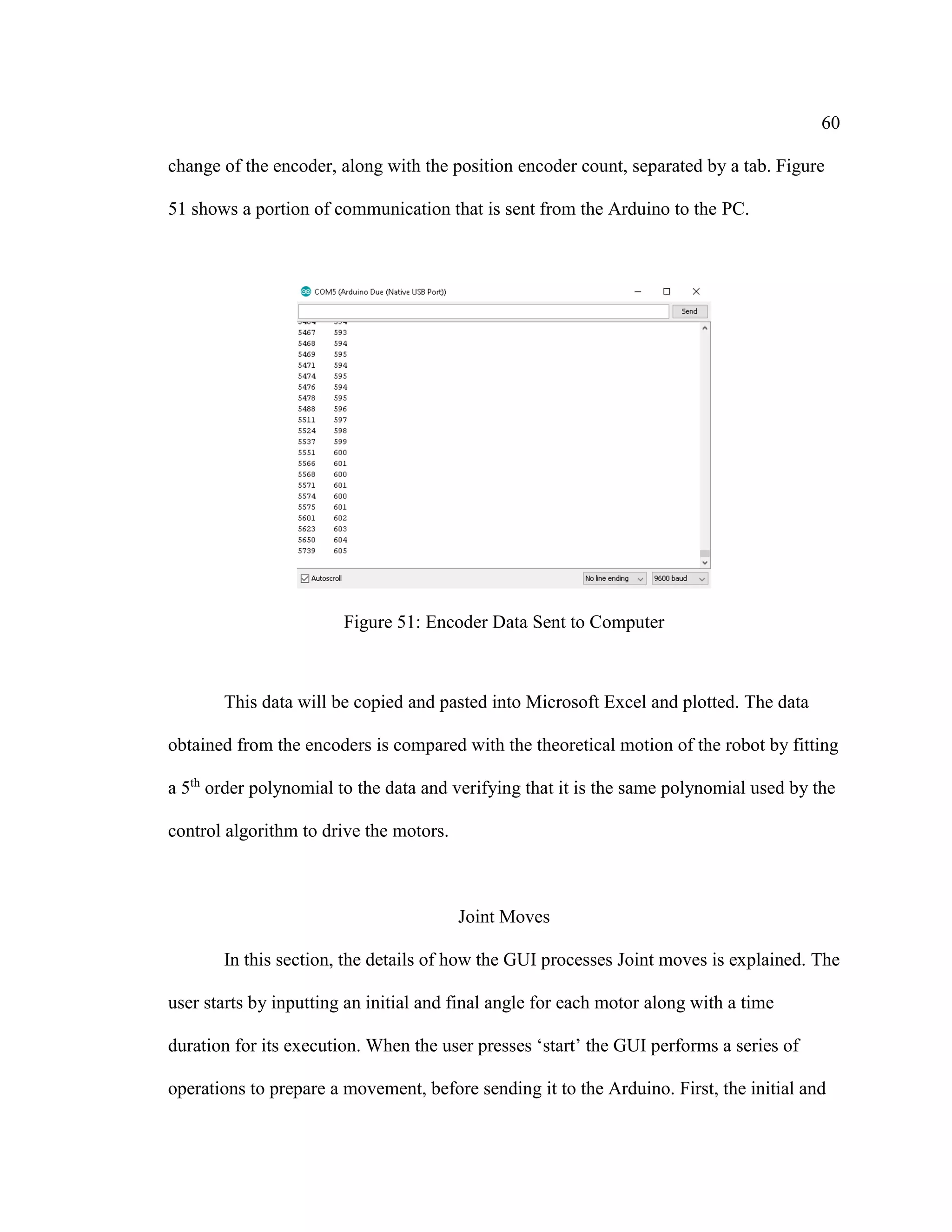

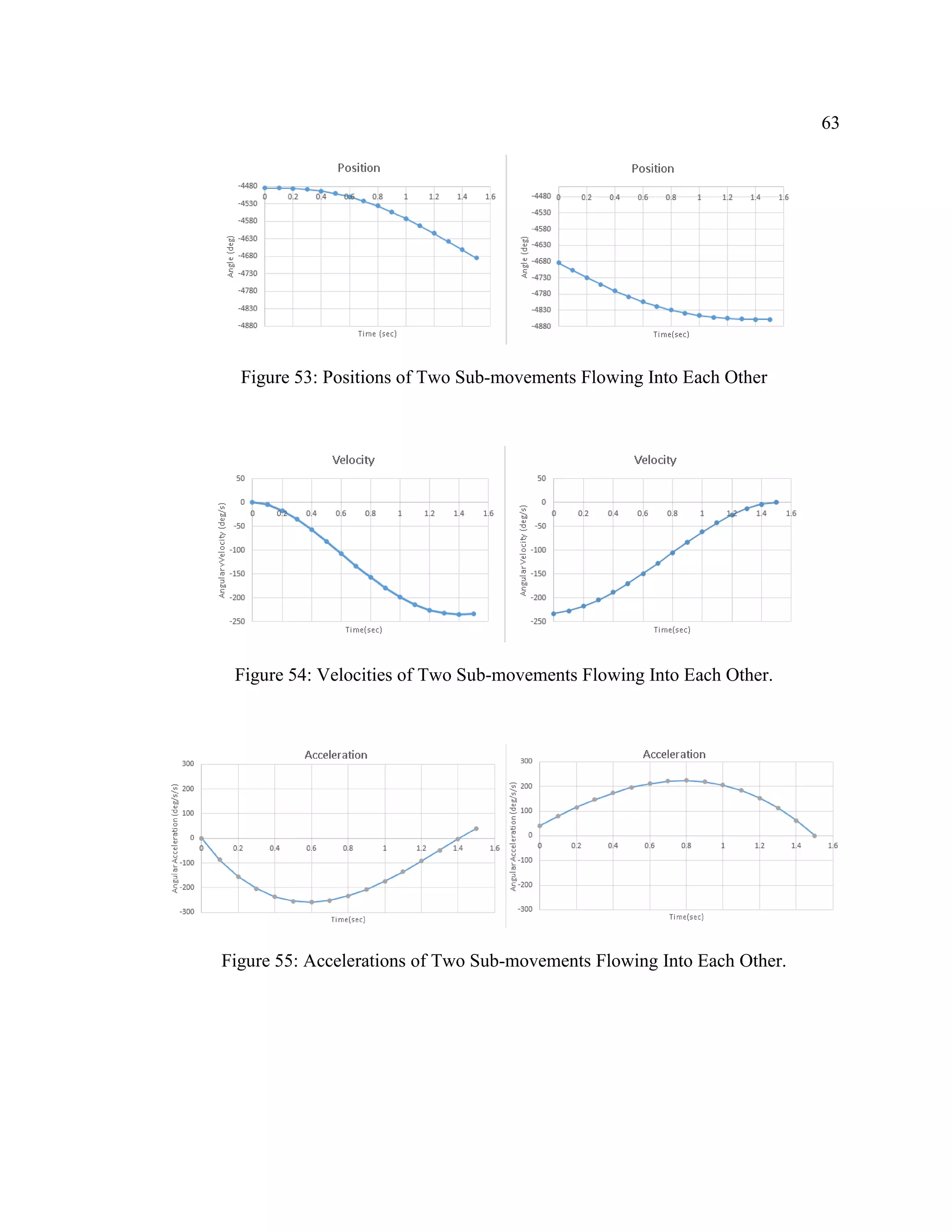

![62

A joint move causes the robot’s joints to follow 5th

order polynomial trajectories

from their initial angle to their final angle. The resulting motion of the end effector does

not necessarily follow a straight line.

Cartesian Moves

In this section, the details of how the GUI processes Cartesian moves is

explained. Cartesian moves are handled much in the same way as joint moves. One

difference however is that before the trajectories are generated, the inverse pose

kinematics is done to convert the user inputs into lengths. Just like a joint move, a

Cartesian move causes the motors to follow 5th

order polynomial trajectories from their

initial angles to their final angles. The resulting motion of the end effector does not

necessarily follow a straight line. Generating a 5th

order trajectory for a joint or Cartesian

move is very simple, this is because many of the initial conditions are zero, only the

initial and final angle remain nonzero.

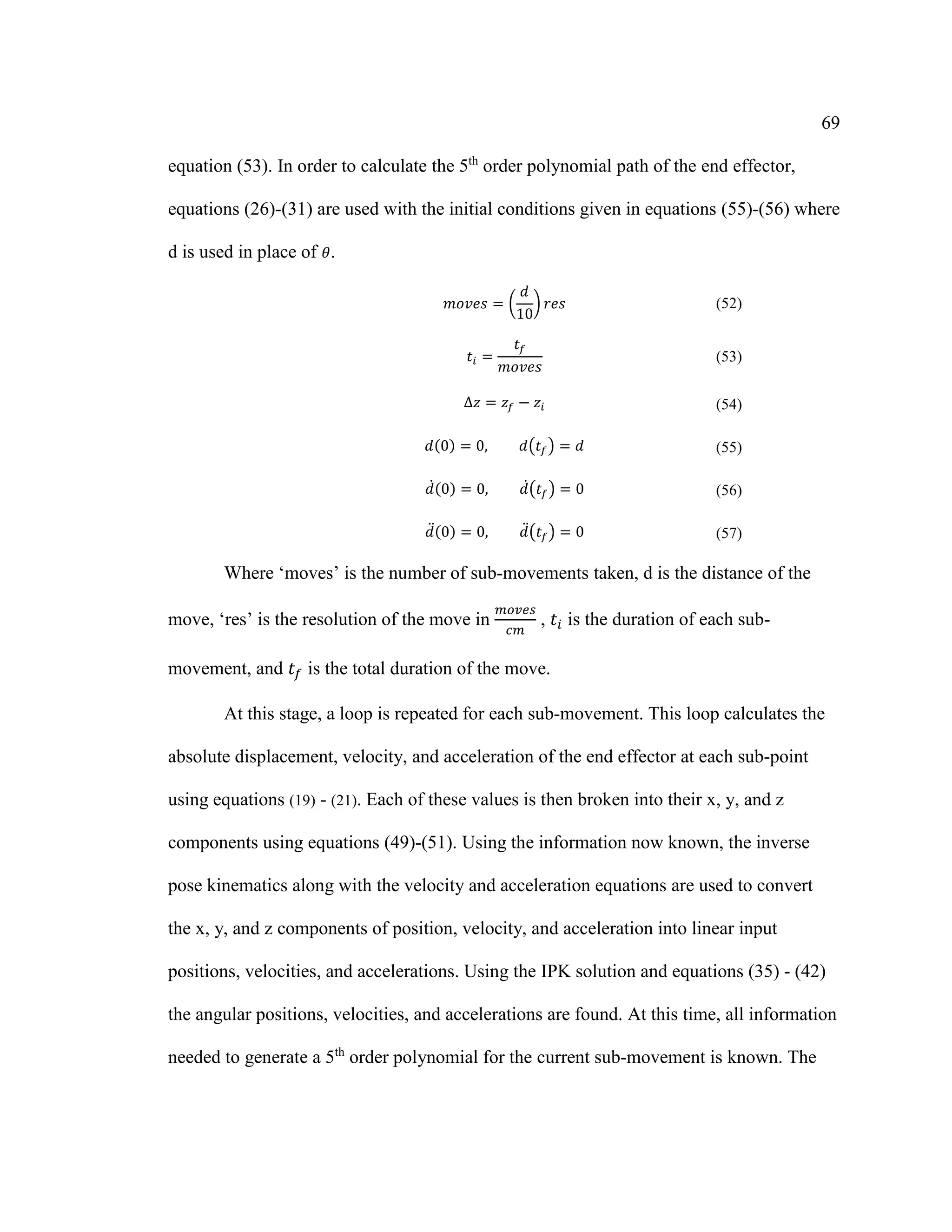

Velocity and Acceleration Equations

In order to execute a linear or circular movement, that movement must be broken

into many smaller sub-movements lying on the desired path [41]. These sub-movements

must flow together smoothly without stopping or jerking. In order to accomplish this, the

points where two sub-movements connect must share the same angular position, velocity,

and acceleration. Figure 53-Figure 56 demonstrate this and shows a movement which is

broken into two 5th order polynomial trajectories.](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-62-2048.jpg)

![64

Figure 56: Jerk of Two Sub-movements Flowing Into Each Other.

In order to know the angular position, velocity, and acceleration at the junctions

between sub-movements, an expression must be known relating them to end effector

position, velocity, and acceleration which is known. Derived by R. Williams II, the

relations between end effector velocity and linear input velocity are shown in equations

(35)-(37) [5]. Using these relations the angular shaft velocities can be calculated using

equation (38).

(𝑥 + 𝑎)𝑥̇ + (𝑦 + 𝑏)𝑦̇ + (𝑧 + 𝐿1)𝑧̇ = −(𝑧 + 𝐿1)𝐿̇1 (35)

(𝑥 − 𝑎)𝑥̇ + (𝑦 + 𝑏)𝑦̇ + (𝑧 + 𝐿2)𝑧̇ = −(𝑧 + 𝐿2)𝐿̇2 (36)

𝑥𝑥̇ + (𝑦 + 𝑐)𝑦̇ + (𝑧 + 𝐿3)𝑧̇ = −(𝑧 + 𝐿3)𝐿̇3 (37)

𝜃̇𝑖 =

𝐿̇ 𝑖

𝜋𝑟

(38)

Where L is the linear input position, r is the timing pulley radius, and a, b, and c

are constants given in equations (5)-(7).

To obtain the angular accelerations at the junctions between sub-movements there

must be an equation relating end effector acceleration to angular shaft accelerations.

Taking the time rate of change of equations (35)-(37) results in equations (39)-(41).](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-64-2048.jpg)

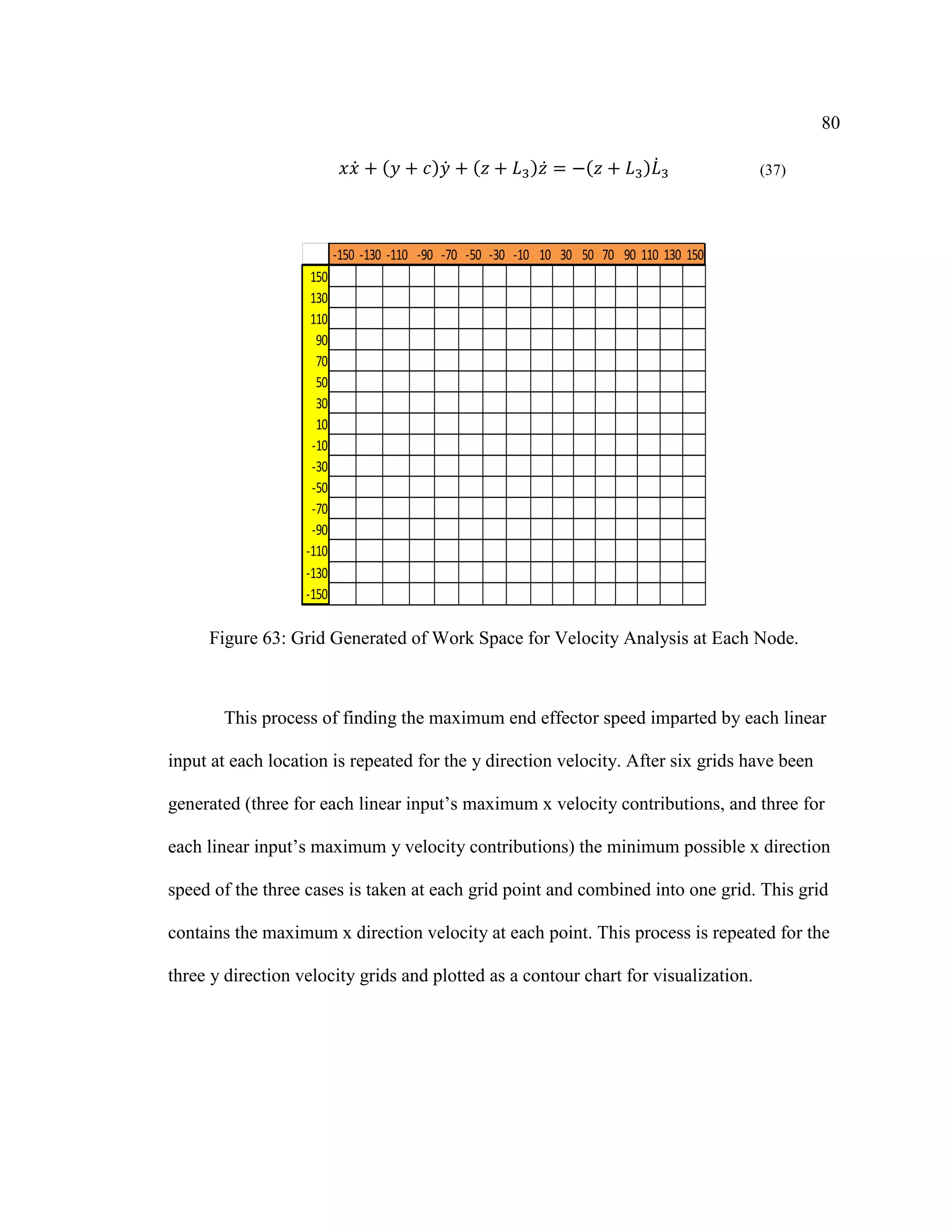

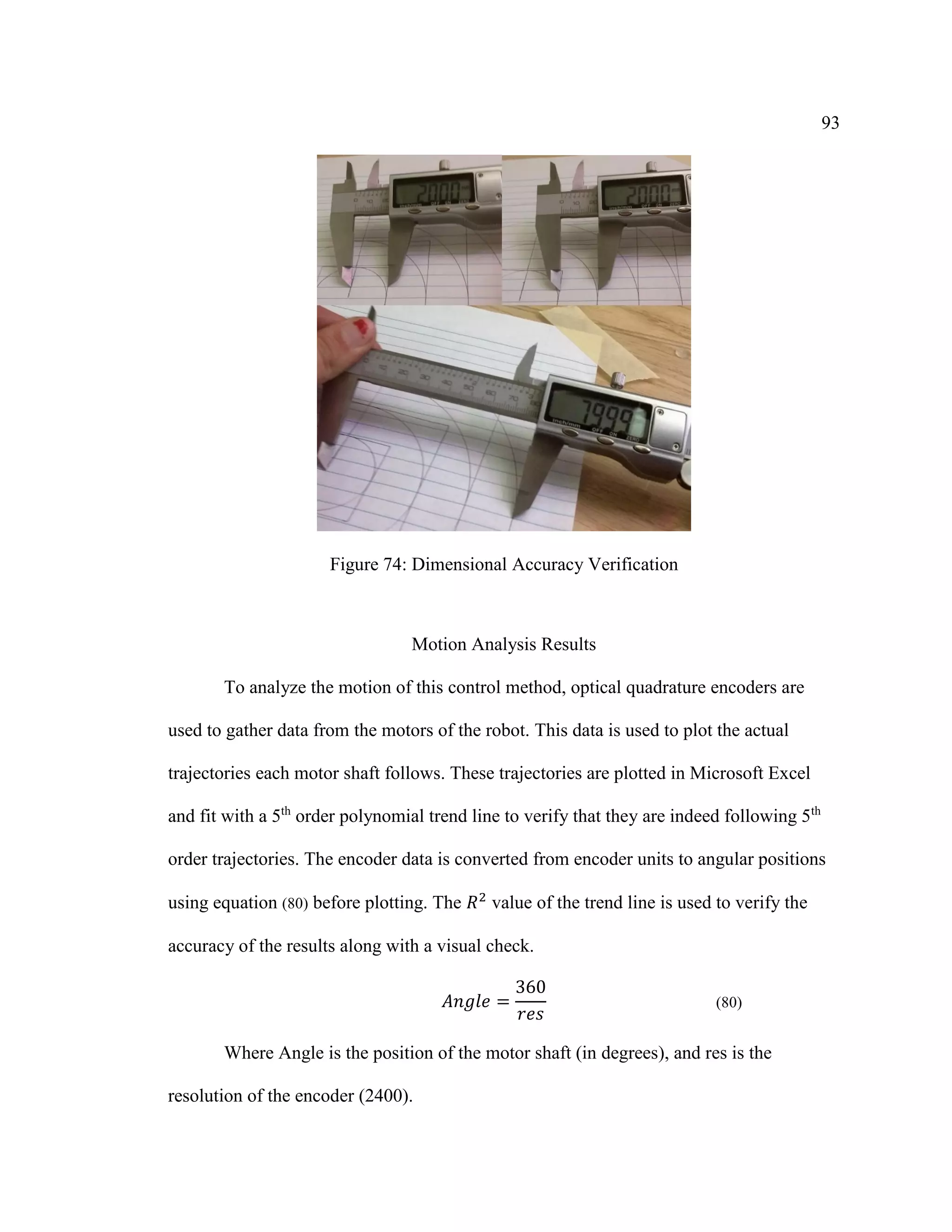

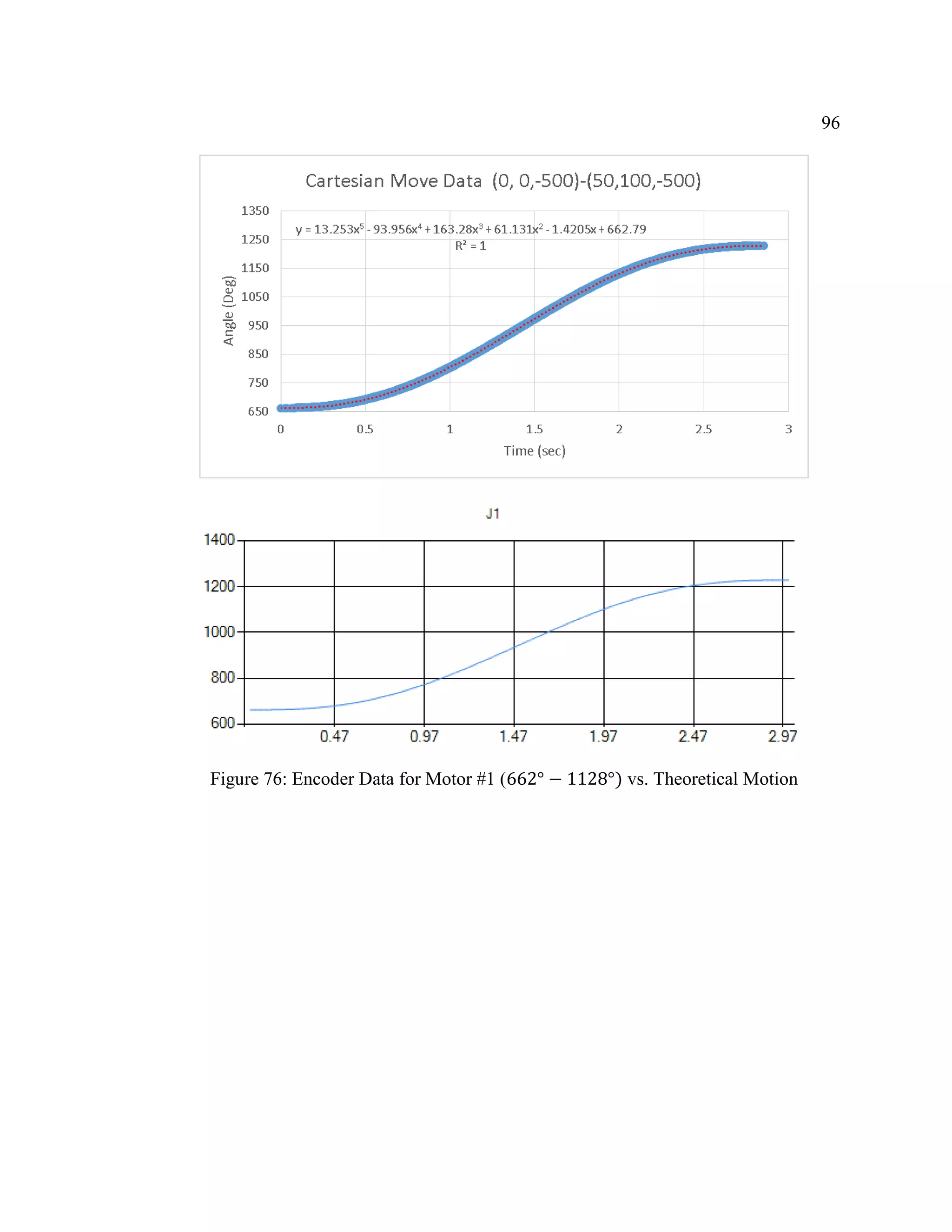

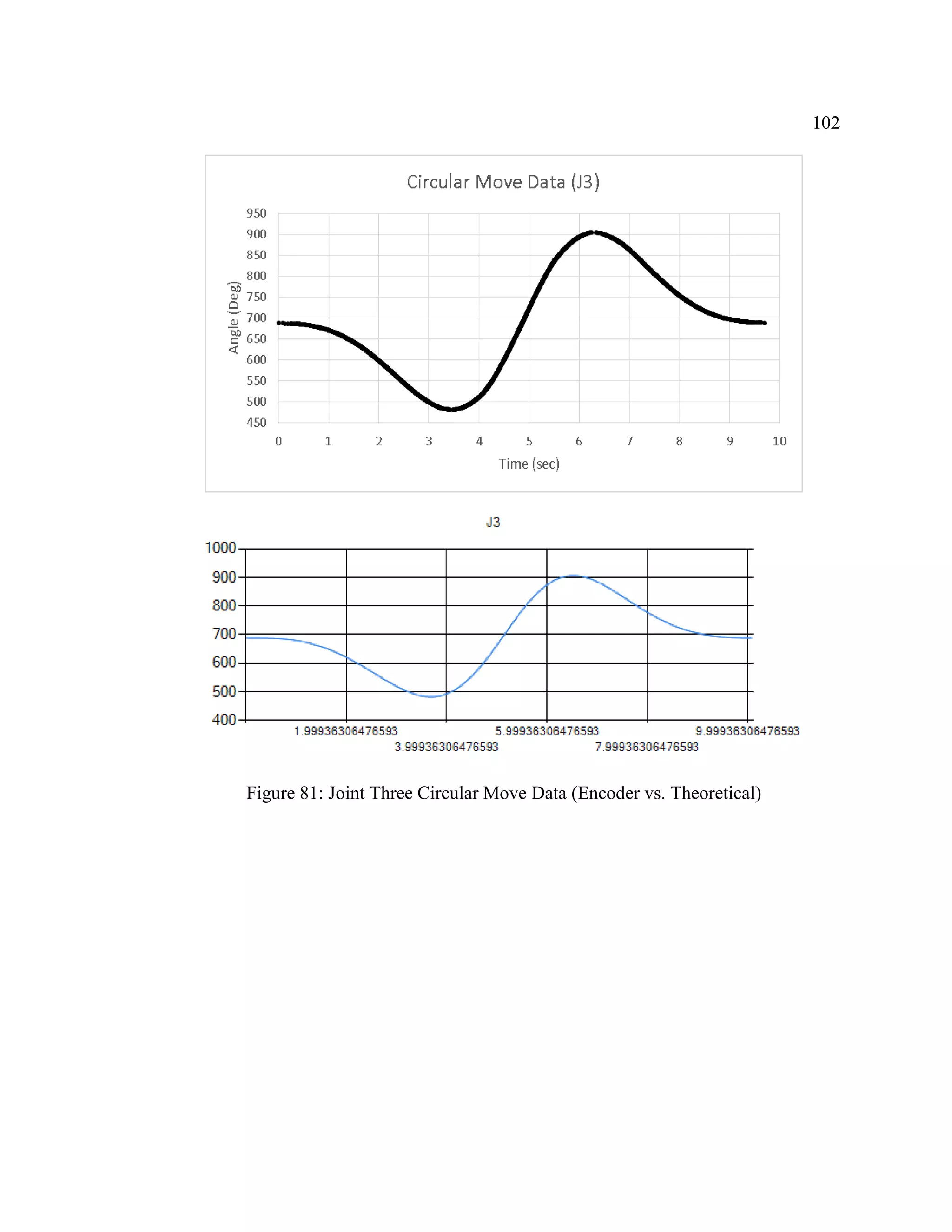

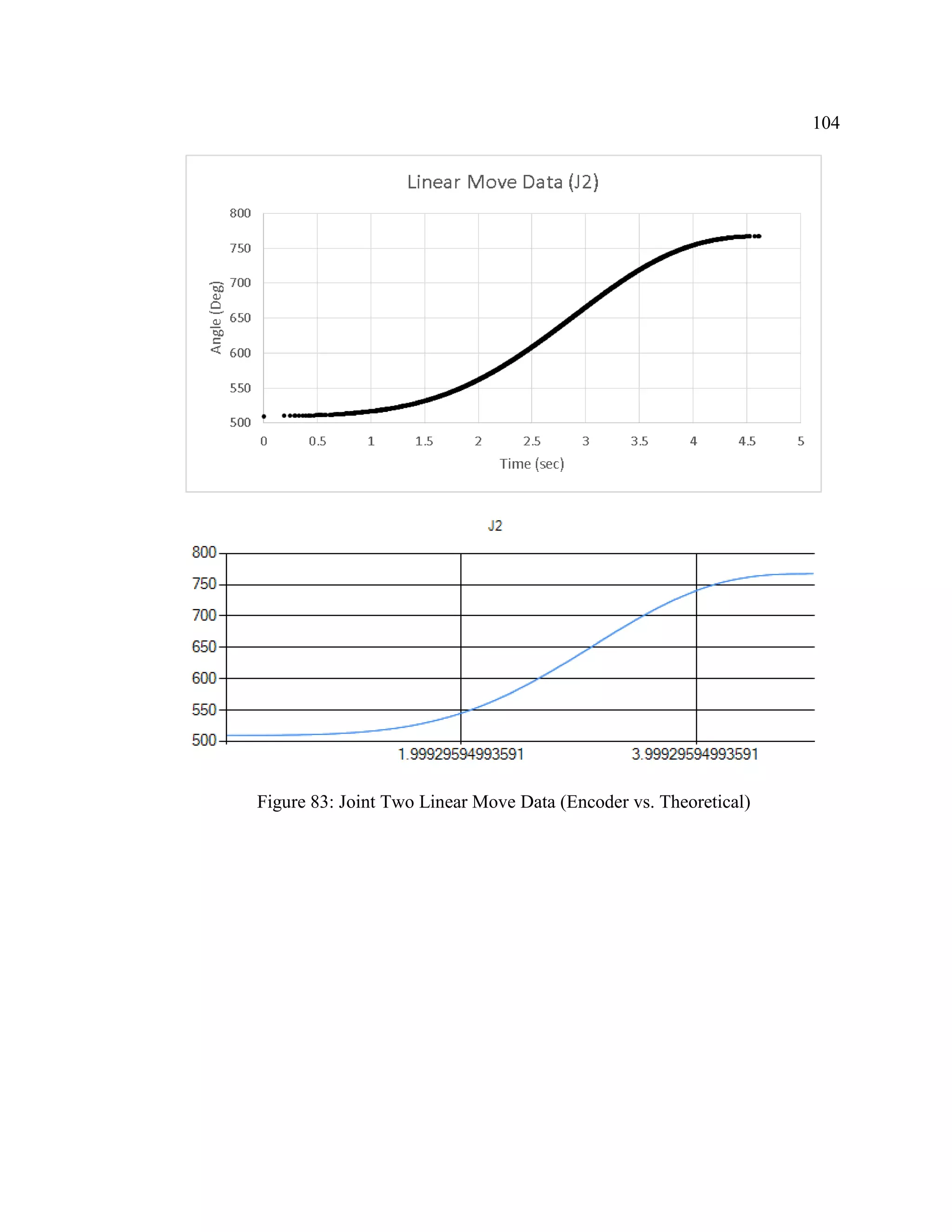

![81

Motion Analysis

Analysis of the robot’s motion is performed using plots of the theoretical motion

generated by the GUI, and by data collected by optical encoders coupled to each motor

shaft. A designated Arduino will be used to collect data from one motor shaft at a time,

which is send to the computer via serial communication. The resulting data can be plotted

in Microsoft Excel, and compared with the theoretical motion.

5th

degree polynomial trend lines will be fit to the data obtained from the

encoders. If the motors are shown to follow 5th

order polynomial trajectories, the control

process is verified, and infinite jerk spikes are said to be prevented (because the third

derivative of a 5th

degree polynomial trajectory results in a finite jerk profile). This

process will be used to analyze Cartesian and joint moves.

In order to analyze linear and circular moves, encoder data will be imported into

Microsoft excel, converted from units of encoder count to units of degrees, and compared

with the theoretical motion of the robot generated by the GUI. If the plots are the same,

the control method is successful.

Accuracy Analysis

The accuracy of the robot will be determined both symbolically and

experimentally. In order to obtain the symbolic solution for the accuracy of the robot in

the x, y, and z direction the error propagation formula (equations (75) and (76)) will be

applied to the forward pose kinematics solution [43]. Matlab is used to calculate the](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-81-2048.jpg)

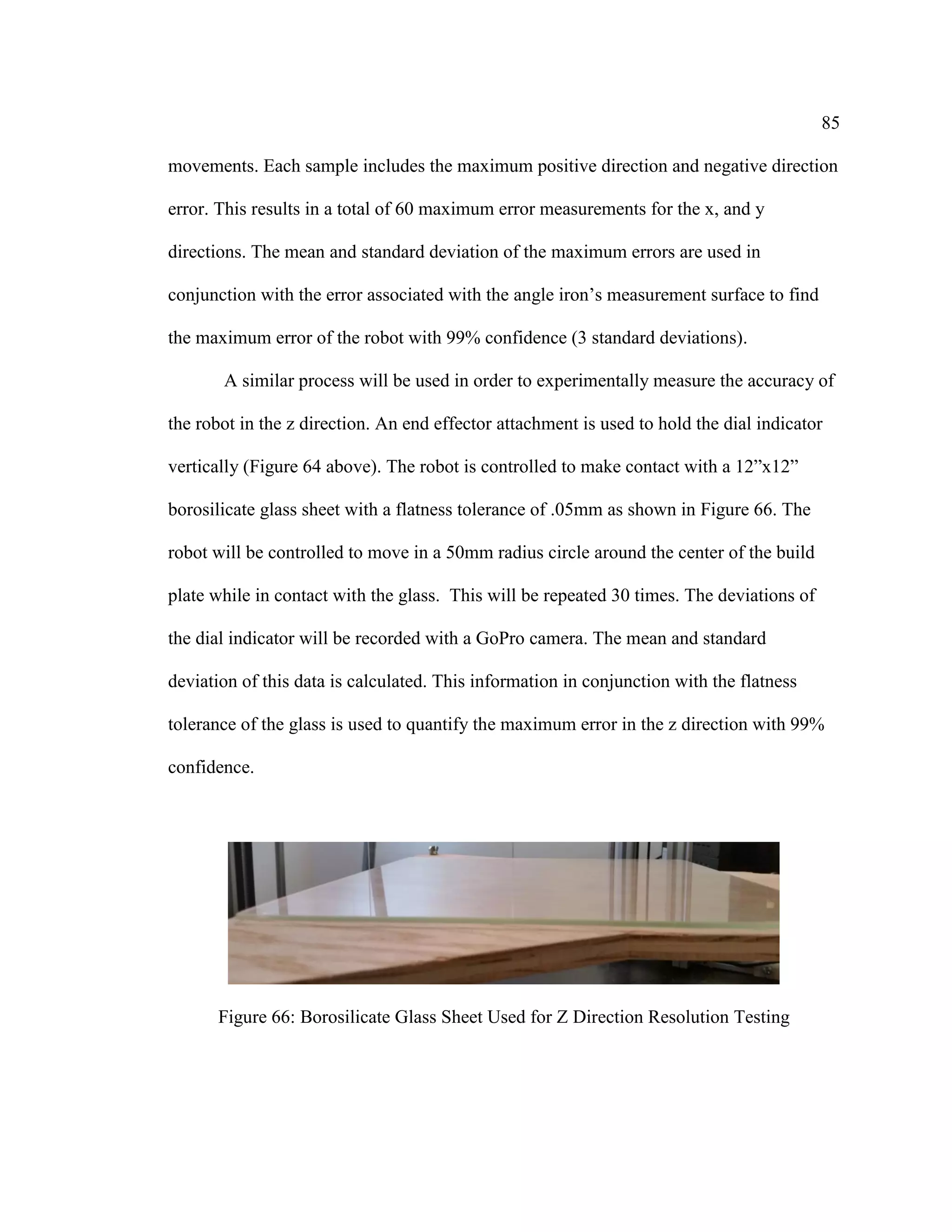

![83

indicator. These values are entered into a website which uses a calibration algorithm

involving the least squares method to give corrections to key dimensions to result in

correct dimensional accuracy and account for any errors in the measurement of frame

dimensions [27]. Because this calibration method is used, the error associated with all

physical dimensions is assumed to be zero.

The accuracy of the robot will be obtained experimentally using a dial indicator

end effector attachment for both the horizontal and vertical directions as shown in Figure

64. The x and y direction resolutions will be obtained using a piece of steel angle iron

clamped to the build plate as shown in Figure 65. A flat surface has been machined into

the top surface of the angle iron with a tolerance of ±.05mm. The robot is controlled to

make contact with one end of the angle iron and move linearly along the surface to the

other end. A GoPro camera will be used to record the deviations in the x and y direction

shown on the dial indicator.](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-83-2048.jpg)

![107

The second thing that could be improved about the GUI is the addition of a G-

code interpreter, and cornering algorithms. Currently, the control method used can

execute all g code commands needed in most applications (linear, and circular moves).

However, these linear and circular moves do not flow into each other, they must come to

a complete stop before executing the next movement. Grbl uses cornering algorithms to

join together movements without stopping in between [44]. A cornering algorithm may

be able to be executed using the same equations presented in this thesis.

A G-code interpreter is the only missing link preventing this control method from

3D printing and performing other tasks such as laser cutting and milling. A G-code

interpreter would read commands from a g-code, and convert them into movements using

the control method developed in this study. It would serve to chain together the

movements to execute a large ‘job’.

Lastly, an overall code optimization could be done on the software. An

experienced programmer may be able to significantly simplify the code, and reduce the

number of lines of code down from the current value of 1379. The GUI has several

aspects that are not as useful as anticipated when added, and a layout that could be more

user-friendly or aesthetically pleasing.

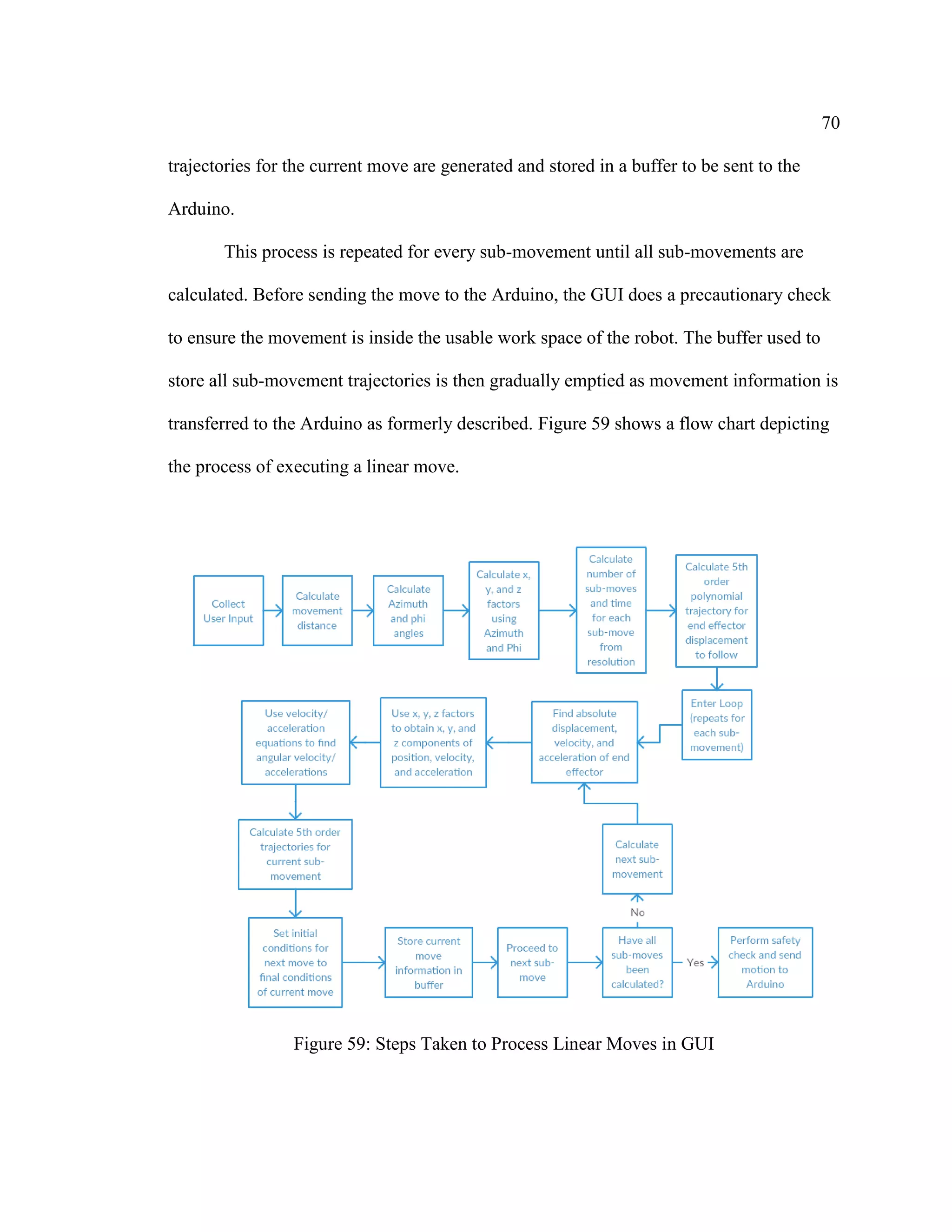

Motion Control Algorithm Discussion

The motion control algorithm is very simple, but was incredibly hard to develop.

Many different methods were tried and failed before success was had. Despite its

simplicity, it does have drawbacks. Using a set frequency to actuate the motors passively](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-107-2048.jpg)

![115

REFERENCES

[1] P.Elinas, J. Hoey, D. Lahey, J.D. Montgomery, 2002, “Waiting with Jose, a vision-

based mobile robot” Robotics and Automation Proceedings. IEEE International

Conference, Vol. 4, 2002, pp. 3698-3705

[2] J. Banks, 2013, “Adding Value in Additive Manufacturing”, IEEE Pulse, pp. 22-26

[3] Z. Pandilov, and V. Dukovski, 2014, “Comparison of the Characteristics between

Serial and Parallel Robots” , Acta Tehnica Corviniensis- Bulletin of Engineering,

Tome VII (2014), pp. 144-160

[4] R. Clavel, 1988, “A Fast Robot with Parallel Geometry,” Proc. Int. Symposium on

Industrial Robots, pp 91-100

[5] R.L. Williams II, 2015, “The Delta Parallel Robot: Kinematics Solutions”, Ohio

University, http://www.ohio.edu/people/williar4/html/pdf/DeltaKin.pdf

[6] R. Kelaiaia, O. Company, A. Zaatri, 2011,”Multiobjective Optimization of a Linear

Delta Parallel Robot” Mechanism and Machine Theory Vol. 50, pp. 159-178

[7] X. Yang, Z. Feng, C Liu, and X. Ren, 2014, “A Geometric Method for Kinematics of

Delta Robot and its Path Tracking Control”, 14th International Conference on

Control, Automation and Systems (ICCAS 2014), pp. 509-514.

[8] S. Stan, M. Minic, C. Szep, R. Balan “Performance Analysis of 3 DOF Delta Parallel

Robot” 2011, Yokohama, Japan

[9] “Arc Welding Robot” [Online].Available: www.fanucrobotics.com [Accessed: 2-29-

2016]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-115-2048.jpg)

![116

[10] R.L. Williams II, 2011, “Improved Robotics Joint Space Trajectory Generation with

Via Point”, Proceedings of the ASME 2011 International Design Engineering

Technical Conferences & Computers and Information in Engineering Conference,

pp. 1-8

[11] C. Lewin, 2007, “Mastering Motion Profiles” [Online].Available:

http://machinedesign.com/motion-control/mastering-motion-profiles [Accessed:

2-29-2016]

[12] K.H. Kim, Y.H. Choi, H. Jung, 2015, “Infeed Control Algorithm of Sorting System

Using Modified Trapezoidal Velocity Profiles”, ETRI Journal Vol.37 No.2.

Pp.328-337

[13] S.B. Niku, 2010, “Introduction to Robotics Analysis, Systems, Applications”,

Prentice Hall, Upper Saddle River, NJ

[14] R.L. Norton, 2002, “Cam Design and Manufacturing Handbook, Vol.1” Industrial

Press, New York

[15] B. Knežević, B. Blanuša, D. Marčetić, 2011 “Model of Elevator Drive with Jerk

Control”, ICAT 2011 International Symposium, pp.1-5

[16] “Current Limiting Factors for 3D Printer Performance” [Online]. Available:

http://forums.reprap.org/read.php?70,246345 [Accessed: 3-1-2016]

[17] J.I. Quinones, 2012 “Applying Acceleration and Deceleration Profiles to Bipolar

Stepper Motors”, Texas Instruments Inc.

[18] “Linear Speed Control of Stepper Motor” 2006 Atmel Corporation

[19] J.J. Craig, 2005 “Introduction to Robotics 3rd Edition”](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-116-2048.jpg)

![117

[20] B. Evans, 2012, “Practical 3D Printers” Springer Science, NY

[21] S.S. Skogsrud, 2009,“Motion Control for Machines that Make Things”[Online].

Available: http://bengler.no/grbl [Accessed: 3-1-2016]

[22] Parker Motion Control, “Custom Profiling, S-Curve Profiling”[Online]. Available:

http://www.parkermotion.com/manuals/6k/6K_PG_RevB_Chp5_CustomProfiling

.pdf [Accessed: 3-1-2016]

[23] “ORION Delta 3D Printer” [Online]. Available: www.adafruit.com [Accessed: 3-2-

2016]

[24] “Kossel Mini” [Online]. Available: www.think3Dprint3D.com [Accessed: 3-2-2016]

[25] “Deltaprintr” [Online]. Available: deltaprintr.com [Accessed: 3-2-2016]

[26] “Fanuc M-1iA” [Online]. Available: www.fanucamerica.com [Accessed: 3-2-2016]

[27] “Delta Printer Least-Squres Calibration Calculator” [Online]. Available:

http://escher3D.com/pages/wizards/wizarddelta.php [Accessed: 3-3-2016]

[28] “3D Printed Delta Robot Universal Joint” [Online]. Available: www.reprap.org

[Accessed: 3-1-2016]

[29] “Magnetic Ball Joint” [Online]. Available: www.3Dprintingindustry.com [Accessed:

3-1-2016]

[30] “Restrictive Spherical Joint Orientation” [Online]. Available:

http://reprap.org/mediawiki/images/thumb/f/f0/HeliumFrogDeltatoolplatform01.j

pg/600px-HeliumFrogDeltatoolplatform01.jpg [Accessed: 3-1-2016]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-117-2048.jpg)

![118

[31] A. Codourey, 1998, “Dynamic Modeling of Parallel Robots for Computed-Torque

Control Implementation”, The International Journal of Robotics Research, pp.

1325-1336

[32] “Pololu Robotics & Electronics” [Online]. Available: www.pololu.com [Accessed:

3-1-2016]

[33] “Arduino Due Specifications” [Online]. Available:

https://www.arduino.cc/en/Main/ArduinoBoardDue [Accessed: 3-1-2016]

[34] J. Valvano, and R. Yerraball, “Embedded Systems- Shape The World” Chap. 3

[35] R. Clavel, 1990, “Device for the movement and positioning of an element in space”

US Patent 4976582 A

[36] D. Sridhar, 2015, “Mathematical Modeling of Cable Sag, Kinematics, Statics, and

Optimization of a Cable Robot” M.S. Thesis, Ohio University

[37] A.J.Koivo, “Fundamentals For Control of Robotic Manipulators” John Wiley and

Sons, New York, NY, USA, 1989

[38] L.Sciavicco and B. Siciliano, “Robotics: Modeling, Planning, and Control”

McGraw-Hill, New York, NY, USA, 2008

[39] R. N. Jazar, “ Theory of Applied Robotics: Kinematics, Dynamics, and Control”

Springer, New York, NY, USA, 2nd edition, 2010

[40] “DeltaMaker: An Elegant 3D Printer” [Online]. Available:

www.deltamaker.com [Accessed: 2-29-2016]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-118-2048.jpg)

![119

[41] C. Guangfeng, Z. Linlin, H. Qingqing, L. Lei, and S. Jiawen, 2012, “Trajectory

Planning of Delta Robot for Fixed Point Pick and Placement”, Fourth

International Symposium on Information Science and Engineering, pp. 236-239

[42] “Makerbot Corexy Robot” [Online]. Available: www.3Ders.org [Accessed: 2-29-

2016]

[43] V. Lindberg, 2000, “Uncertainties and Error Propagation. Part I of a manual on

Uncertainties, Graphing, and the Vernier Caliper”

[44] S. Jeon, 2011, “Improving Grbl: Cornering Algorithm” [Online]. Available:

onehossshay.wordpress.com [Accessed: 3-6-2016]](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-119-2048.jpg)

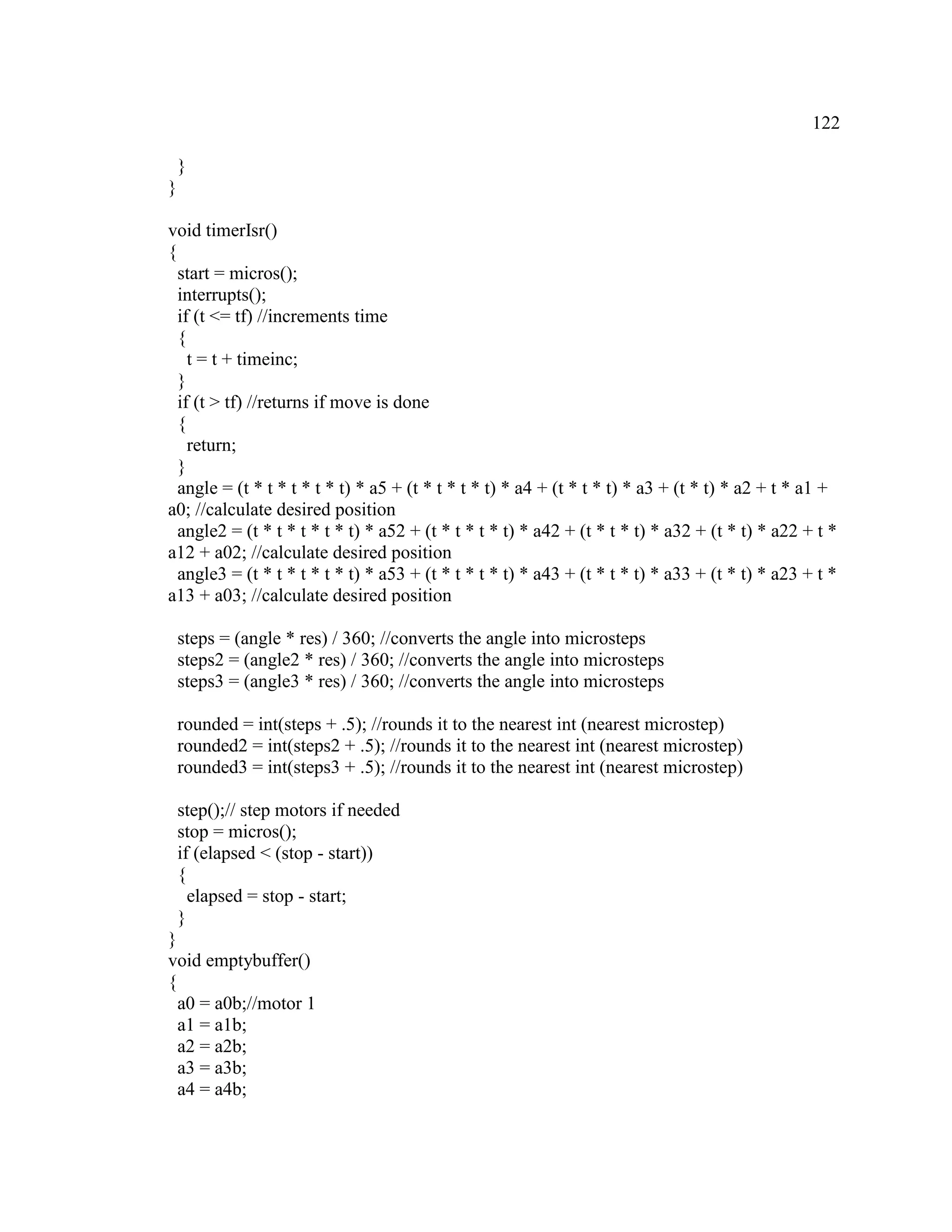

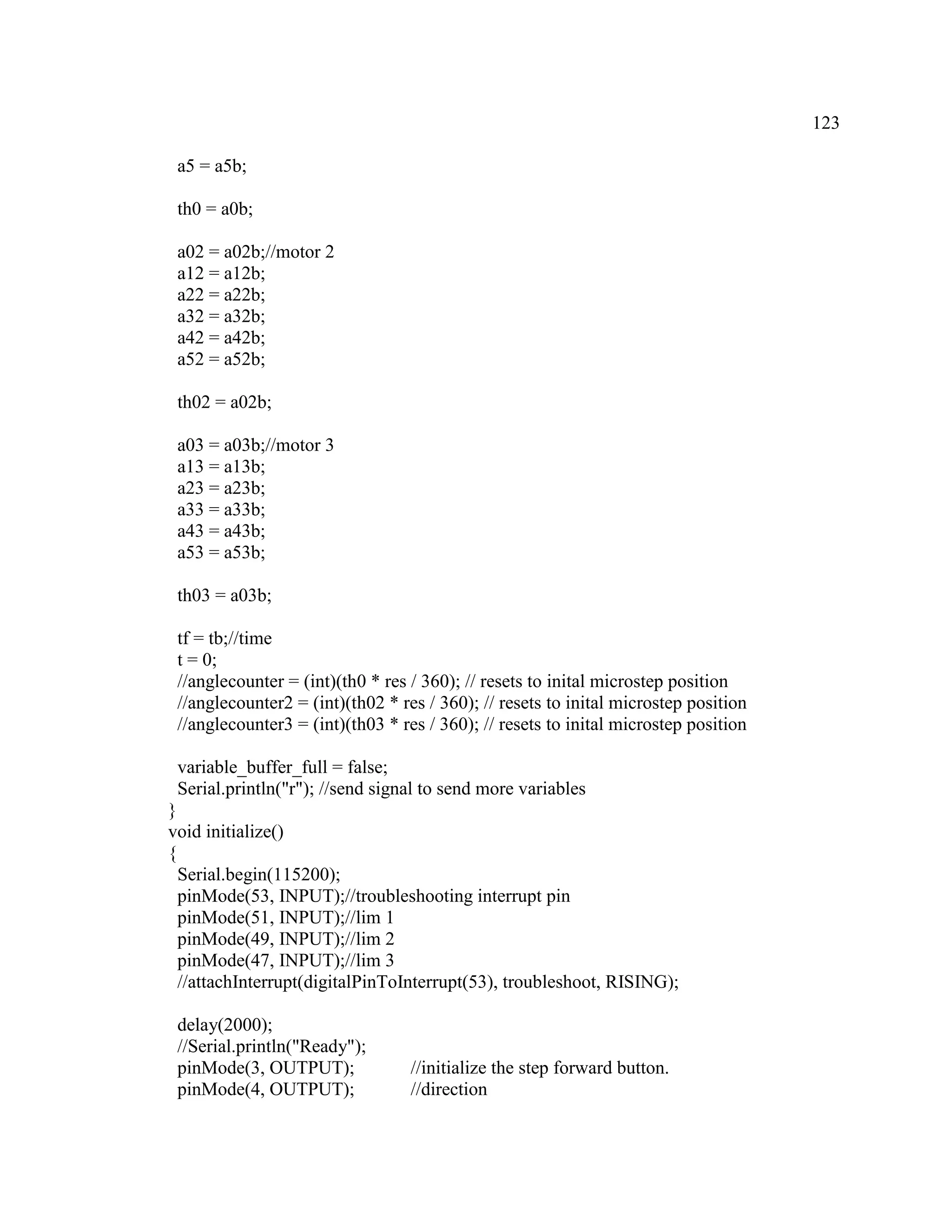

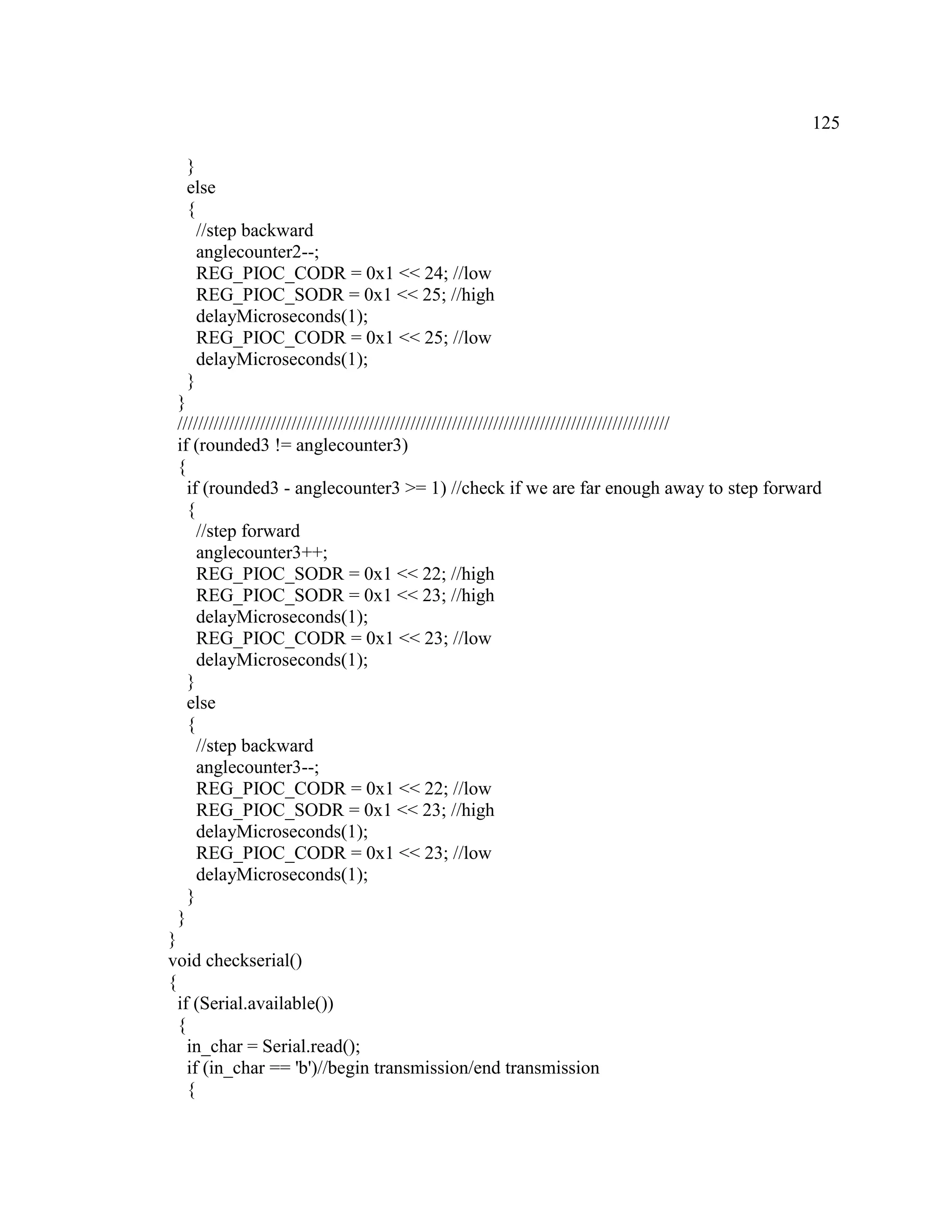

![120

APPENDIX A: MOTION CONTROL ARDUINO CODE

The Arduino code shown below is the entire contents of the motion control

algorithm. It is used to convert messages received from the computer into robot motion.

/*

MAKE SURE YOU SET THE SERIAL BUFFER TO ~500 BYTES. EVEN SIMPLE

MOVES REQUIRE

A SERIAL MESSAGE OF ~126 BYTES TO THE CONTROLLER. THE MORE

COMPLEX ONES ARE

EVEN LARGER. IF YOU HAVE PROBLEMS WITH YOUR MOTORS SEIZING

UP OR ACTING STRANGE

AFTER BEING TOLD TO PERFORM A LINEAR OR CIRCULAR MOVE THIS

MAY BE A RESULT OF NOT

DOING THIS. THE SERIAL BUFFER WILL OVERFLOW.

*/

#include <DueTimer.h>

//serial communication variables

char in_char;

String rec_string = "";

bool record = false;

int a_val_counter = 0, zero_retreat_counter;

float a_buffer[25];

bool variable_buffer_full = false;

String send, info, tab = "t", timestring;

long start, stop, elapsed;

float th0 = 0, thf = 0, th02 = 0, thf2 = 0, th03 = 0, thf3 = 0; //thetas

float tf = 3; //movement duration

bool estop = false, endstop1 = false, endstop2 = false, endstop3 = false, zeroed = false;

float res = 3200; //resolution of the stepper in steps/rev

float proctime = 93; //time needed to process interrupt (74)

//anglecounter=current shaft angle, t=current time, angle= value found from poly each

iteration

float angle = 0, angle2 = 0, angle3 = 0;

volatile float t = 0;

float a0, a1, a2, a3, a4, a5, a02, a12, a22, a32, a42, a52, a03, a13, a23, a33, a43, a53;

//polynomial coefficients

float a0b, a1b, a2b, a3b, a4b, a5b, a02b, a12b, a22b, a32b, a42b, a52b, a03b, a13b, a23b,

a33b, a43b, a53b; //buffering polynomial coefficients

float th0b = 0, thfb = 0, th02b = 0, thf2b = 0, th03b = 0, thf3b = 0; //buffer theta values

float tb = 0; //time buffer value

float calctime = proctime + 10;](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-120-2048.jpg)

![126

record=false;

rec_string="";

a_val_counter=0;

}

else if (in_char == 'z') //start receiving a variable

{

endstop1=false;

endstop2=false;

endstop3=false;

zeroed=false;

zero();

}

else if (in_char == 's') //start receiving a variable

{

record = true;

rec_string = "";

}

else if (in_char == '!') //emergency stop. reset everything

{

record=false;

a_val_counter=0;

rec_string="";

tf=0;

estop=true;

}

else if (in_char == 'f' && record == true) // terminate current variable reception

{

record = false;

a_buffer[a_val_counter] = rec_string.toFloat();

a_val_counter++;

rec_string = "";

}

else if (record == true)

{

rec_string += in_char;

}

if (a_val_counter == 19)

{

a0b = a_buffer[0];//motor 1 variables

a1b = a_buffer[1];

a2b = a_buffer[2];

a3b = a_buffer[3];

a4b = a_buffer[4];

a5b = a_buffer[5];](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-126-2048.jpg)

![127

a02b = a_buffer[6];//motor 2 variables

a12b = a_buffer[7];

a22b = a_buffer[8];

a32b = a_buffer[9];

a42b = a_buffer[10];

a52b = a_buffer[11];

a03b = a_buffer[12];//motor 3 variables

a13b = a_buffer[13];

a23b = a_buffer[14];

a33b = a_buffer[15];

a43b = a_buffer[16];

a53b = a_buffer[17];

tb = a_buffer[18];//time

variable_buffer_full = true;

a_val_counter = 0;

}

}

}

void troubleshoot()

{

//Serial.println(a_val_counter);

Serial.println(rounded);

Serial.println(anglecounter);

Serial.println(rounded2);

Serial.println(anglecounter2);

Serial.println(rounded3);

Serial.println(anglecounter3);

endstop1=true;

endstop2=true;

endstop3=true;

}

void zero()

{

//51 49 47

anglecounter=0;

anglecounter2=0;

anglecounter3=0;

while (zeroed == false)

{](https://image.slidesharecdn.com/14642f12-28b2-41bf-9341-d403d1324d68-160903204051/75/Oberhauser-Joseph-Thesis-127-2048.jpg)