The document provides information about NTPC Auraiya Gas Power Plant (AuGPP) located in Uttar Pradesh, India. Some key details include:

- AuGPP has a total installed capacity of 652 MW and uses natural gas and naphtha as fuel.

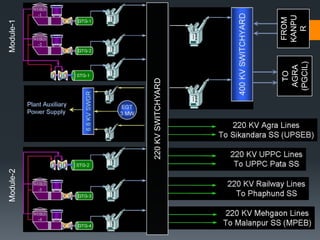

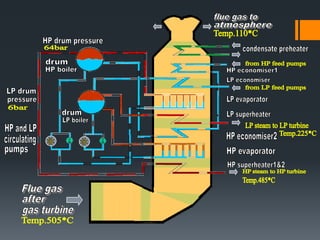

- It uses a combined cycle with two gas turbine modules and two steam turbines to generate power more efficiently.

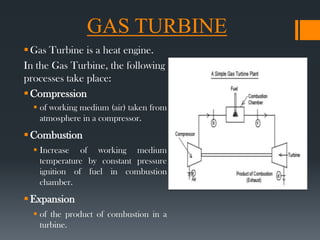

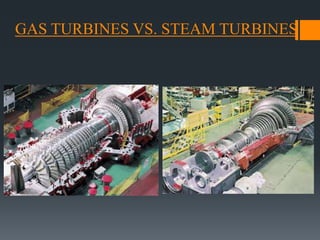

- The plant's main components are gas turbines, steam turbines, waste heat recovery boilers, and generators.

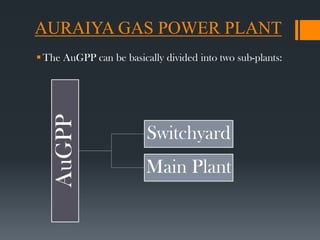

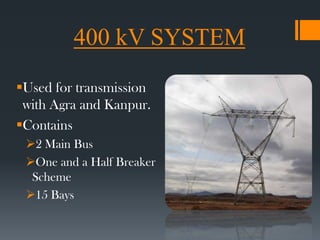

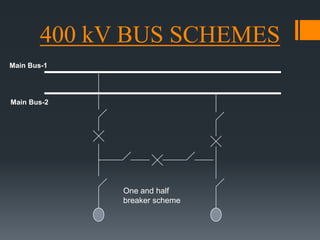

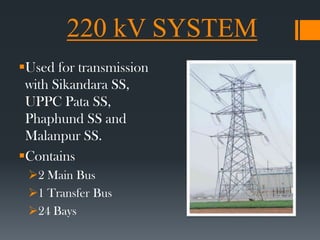

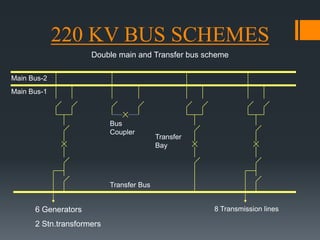

- Electricity is transmitted through a 220kV and 400kV switchyard to various states in northern India.