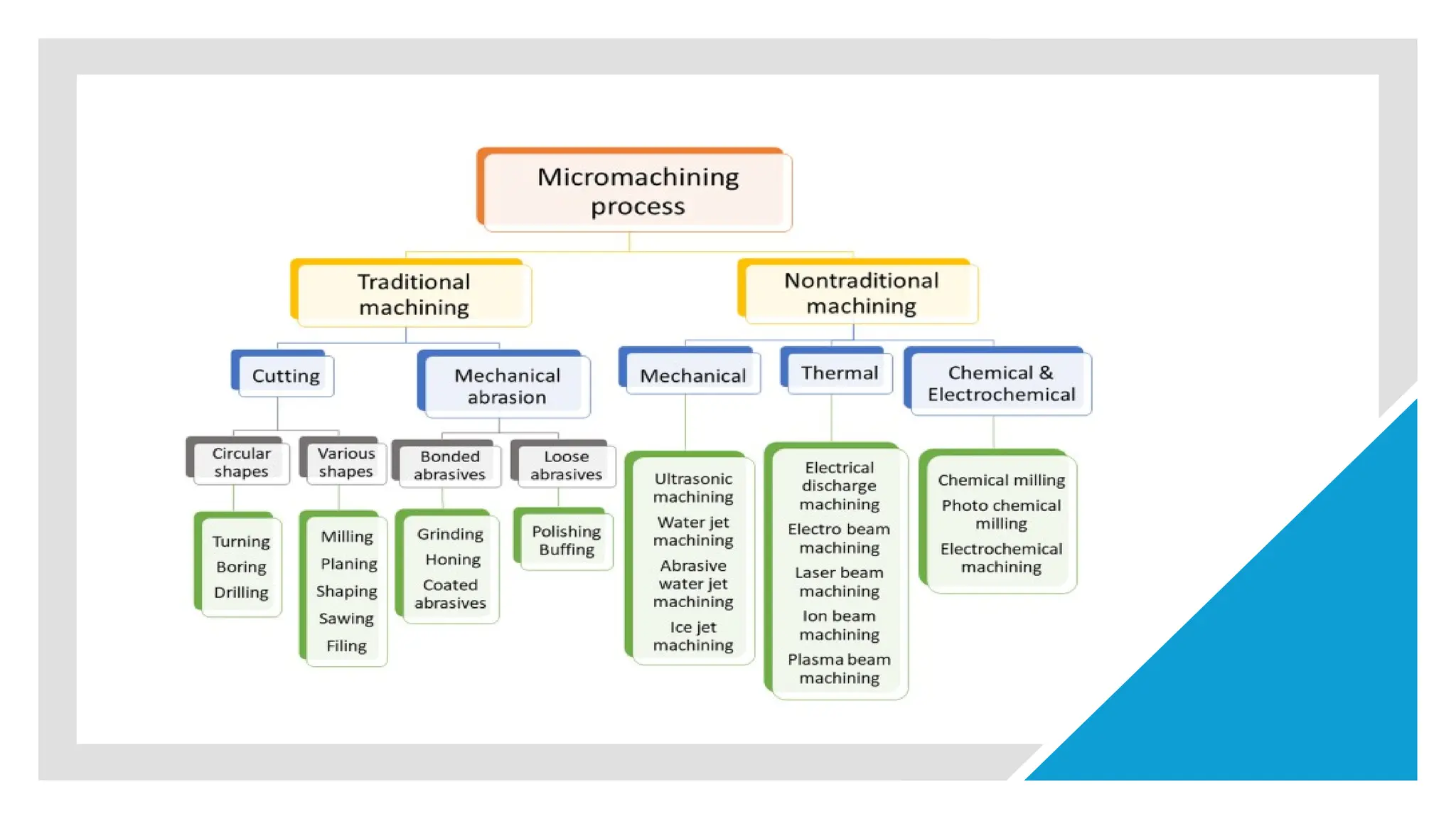

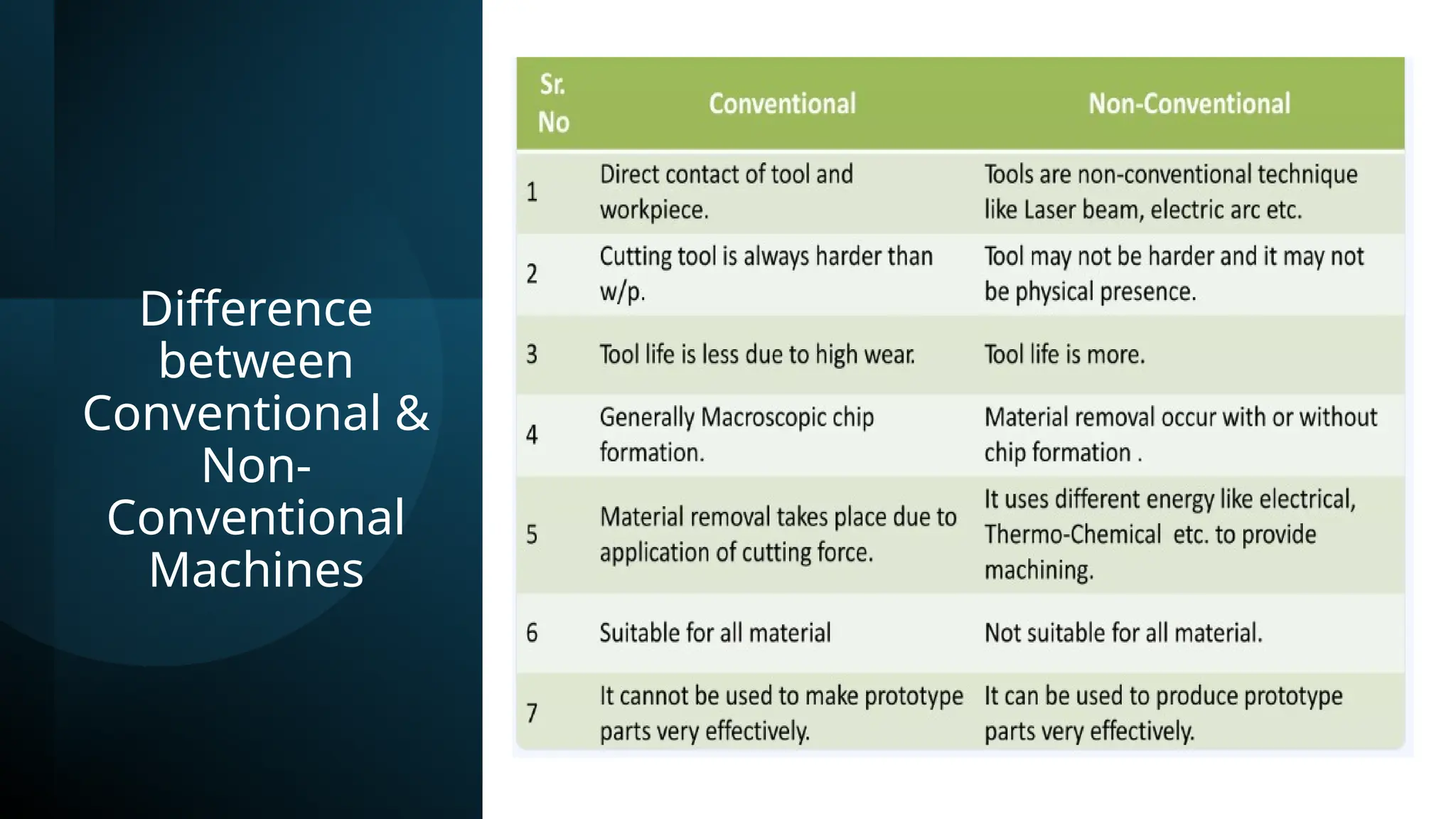

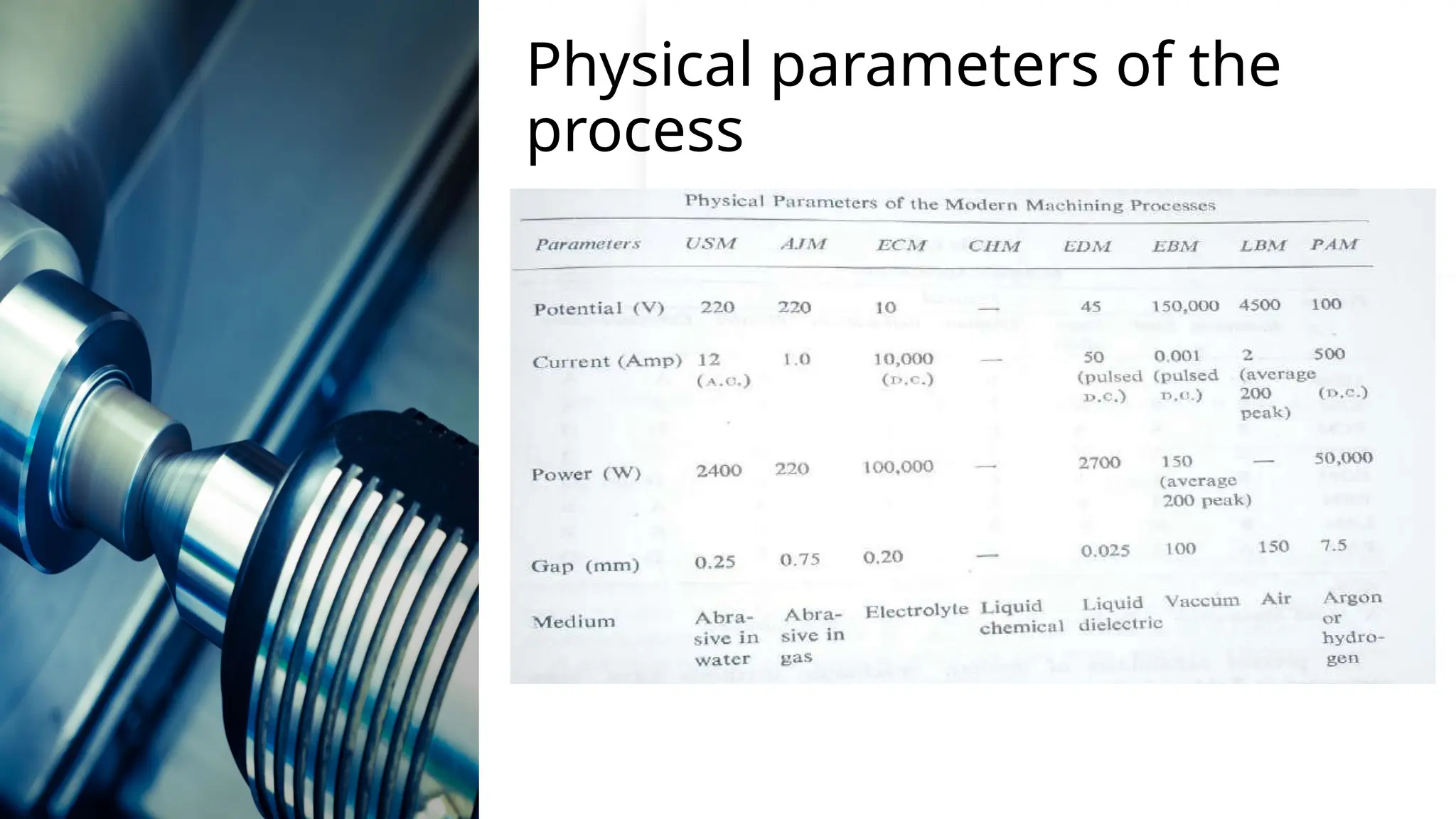

Non-traditional machining (NTM) utilizes various forms of energy to process materials, providing better accuracy and efficiency compared to conventional methods, particularly for hard materials. Despite its higher initial cost and complexity, NTM offers advantages like reduced noise, less waste, and no tool wear. Applications include the production of dies, small holes in fuel injection systems, and complex designs in aerospace and automotive industries.