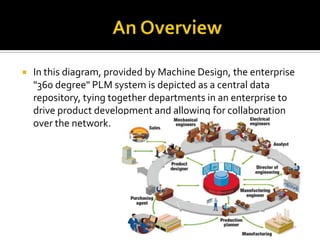

Product lifecycle management (PLM) is the process of managing a product throughout its lifecycle including conception, design, manufacture, and disposal. PLM integrates people, processes, data and systems to provide a centralized product information backbone for companies. PLM software from companies like Siemens and Omnify provide a single source of truth for all product data and ensure the correct parts are ordered and produced according to approved documentation. PLM benefits include reduced time to market, improved quality, and ability to quickly identify sales opportunities.