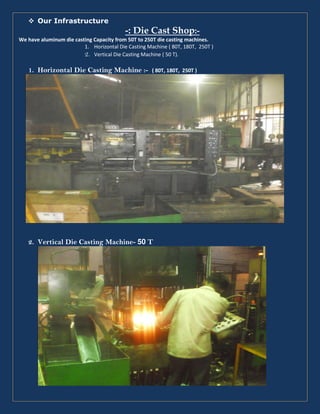

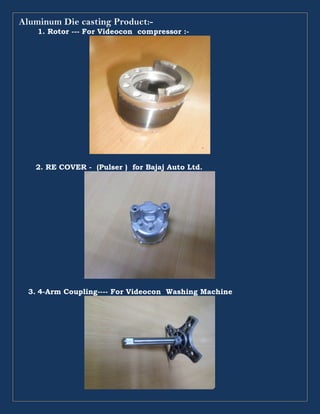

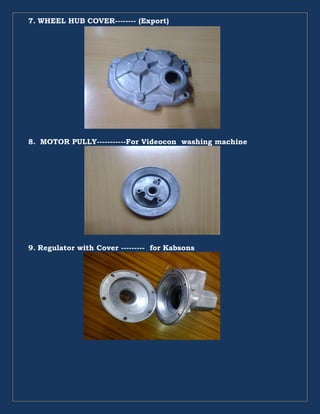

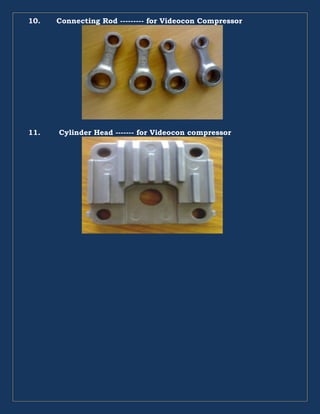

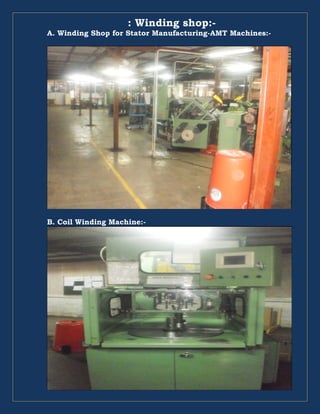

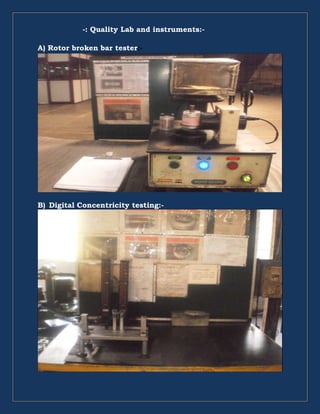

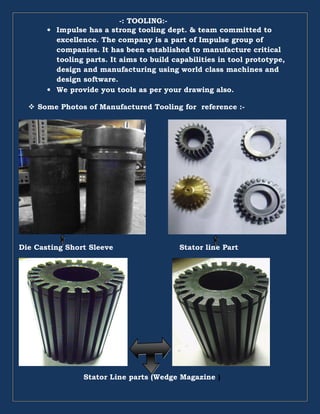

Impulse Electroccon Pvt. Ltd. is a 6-year old Indian company that manufactures hermetic motors and refrigerator compressor motors for companies like Videocon and aluminum die casting components as a sub-vendor for Bajaj Auto Ltd. The company has manufacturing plants in Aurangabad, Maharashtra and an registered office in Indore. Impulse focuses on quality manufacturing and has produced over 3 million motors and die cast components. The company aims to grow its production and achieve zero defects through its skilled workforce and ISO 9001:2008 certification.