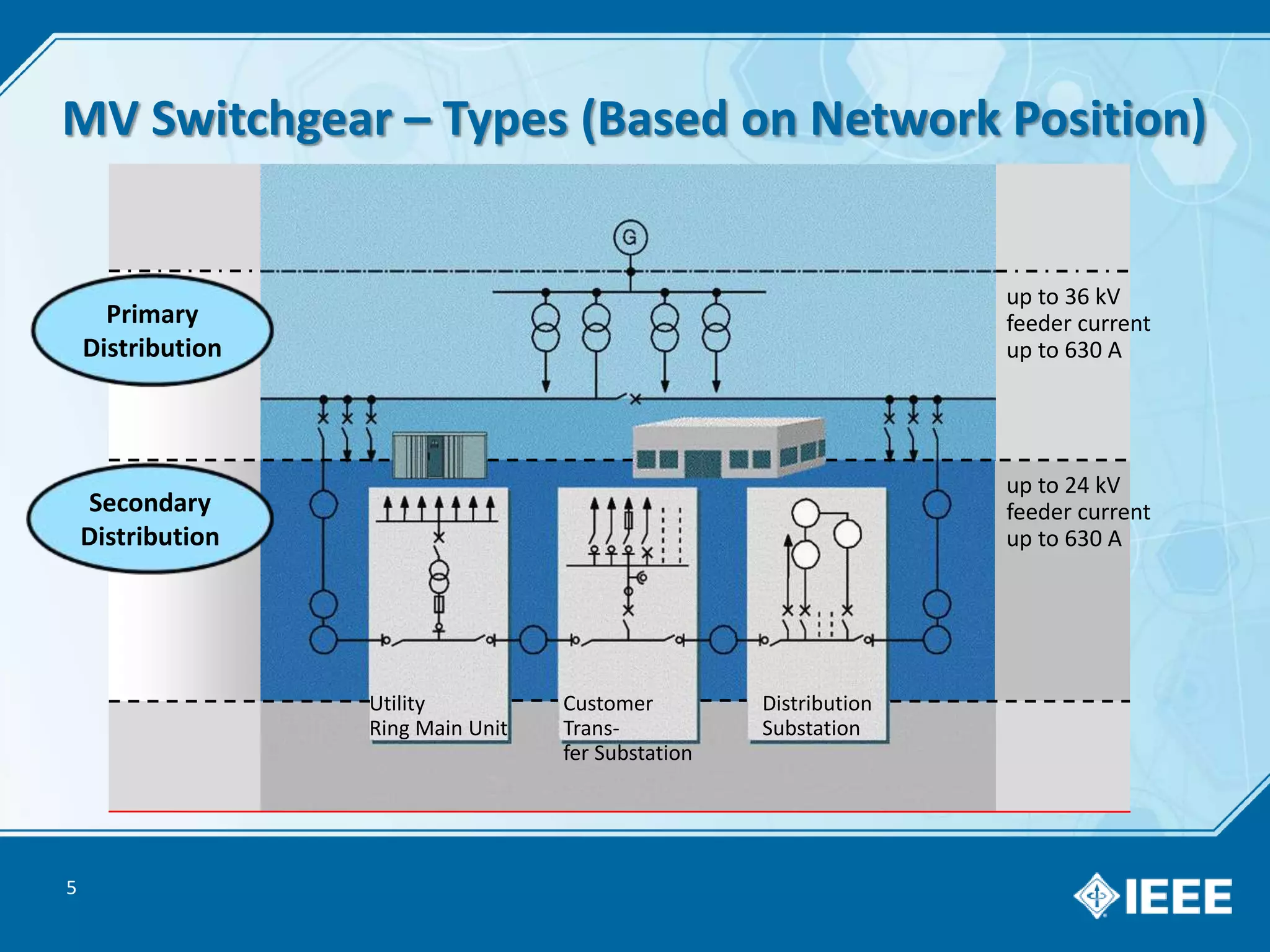

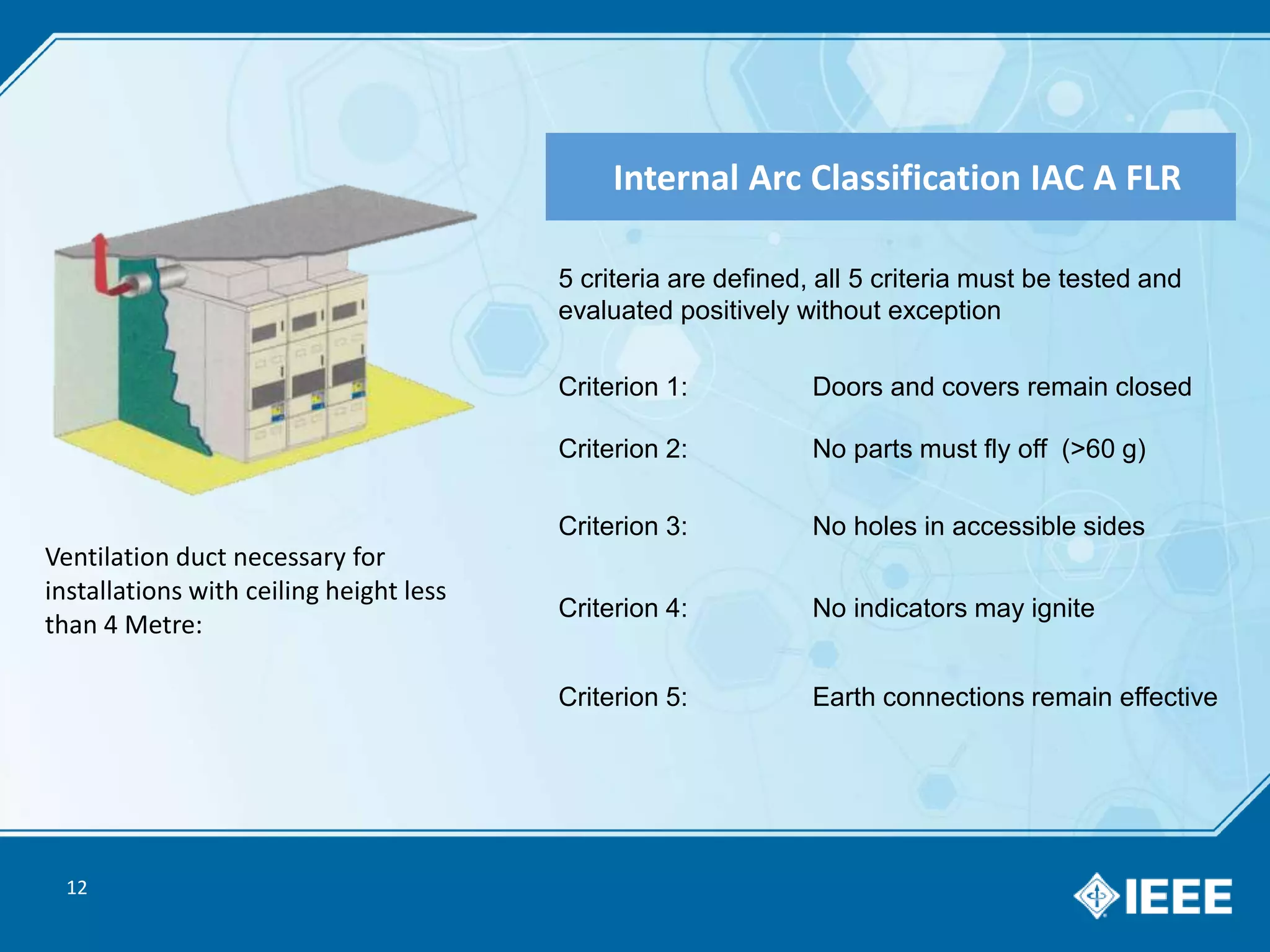

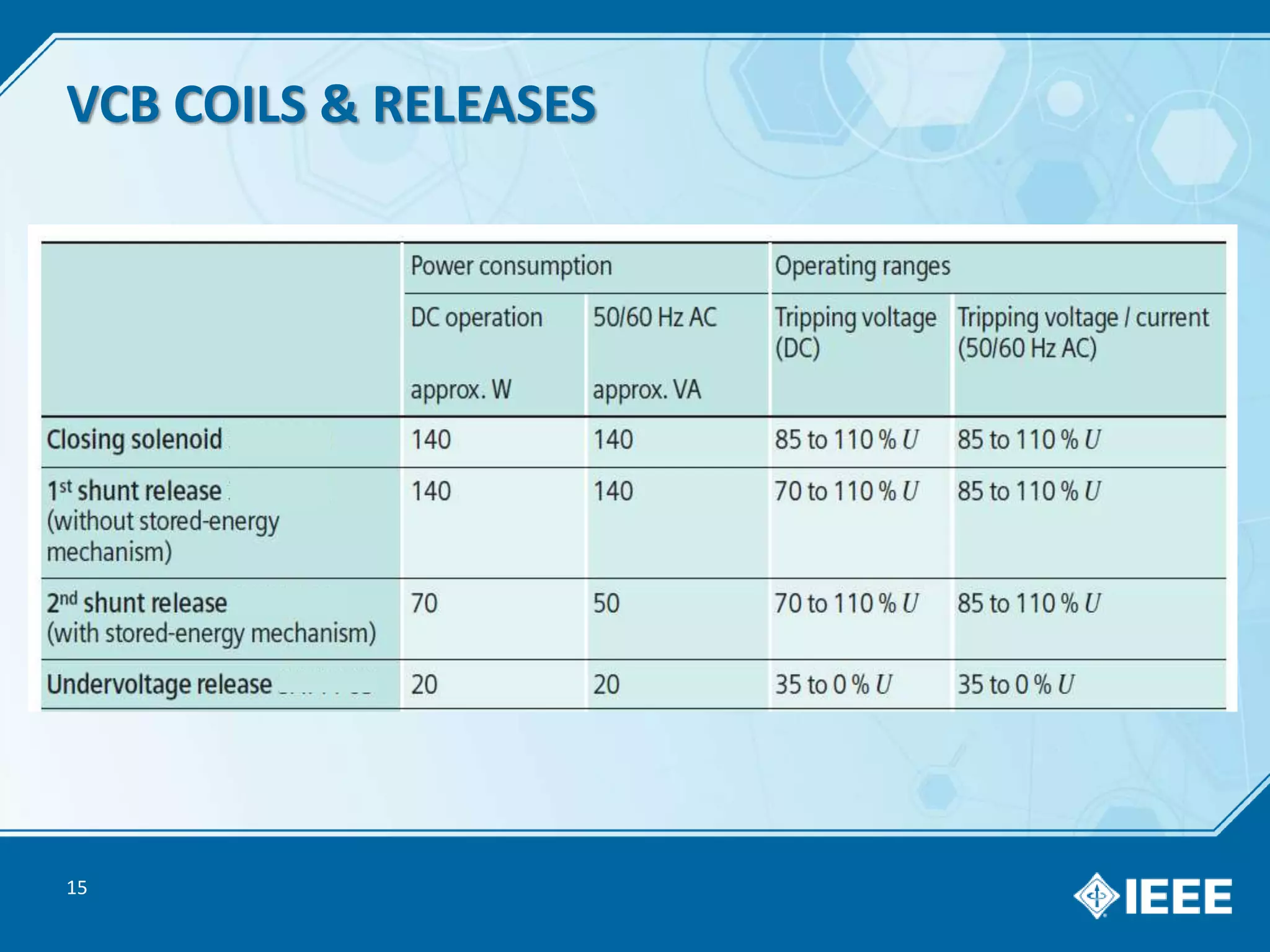

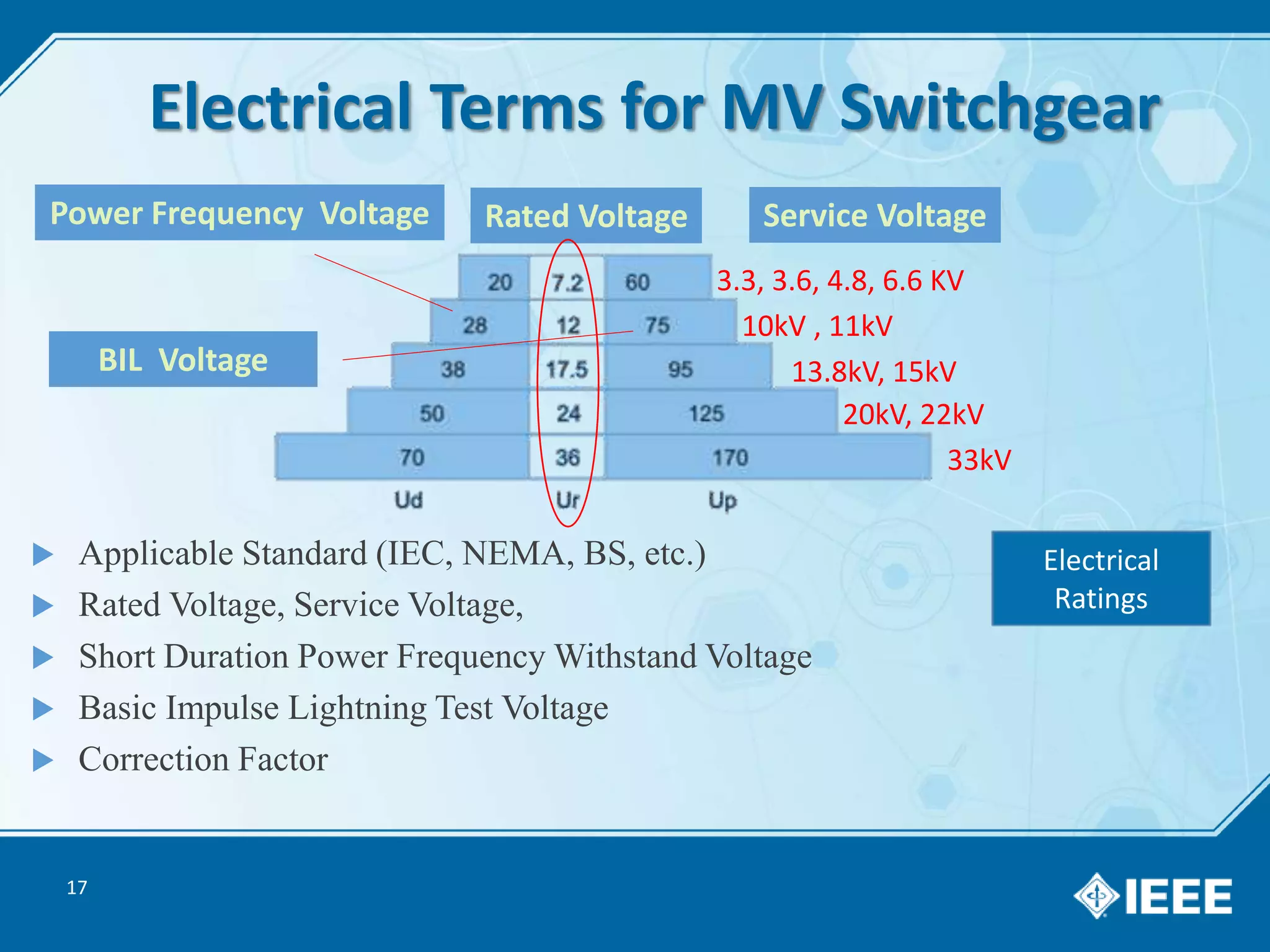

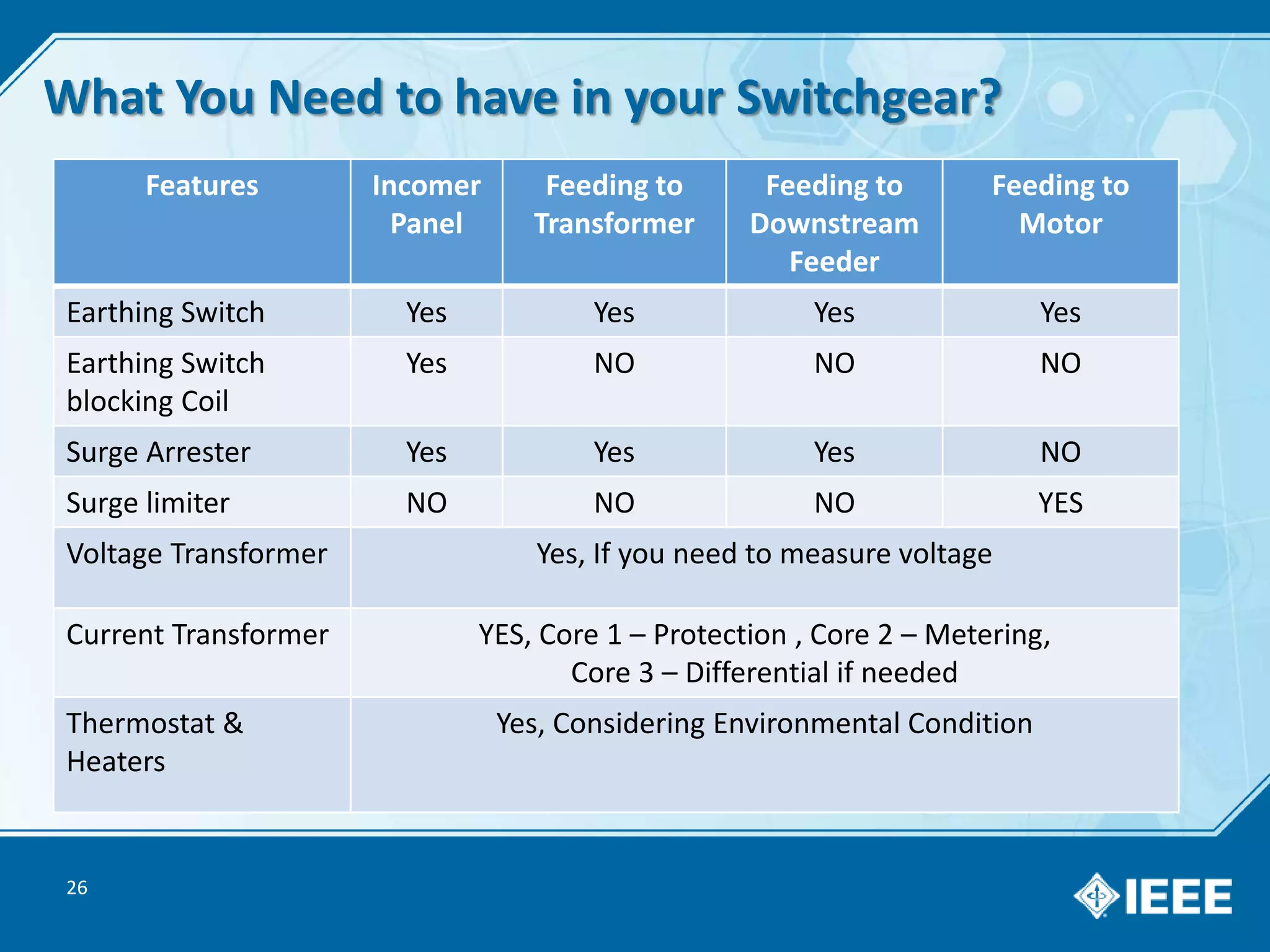

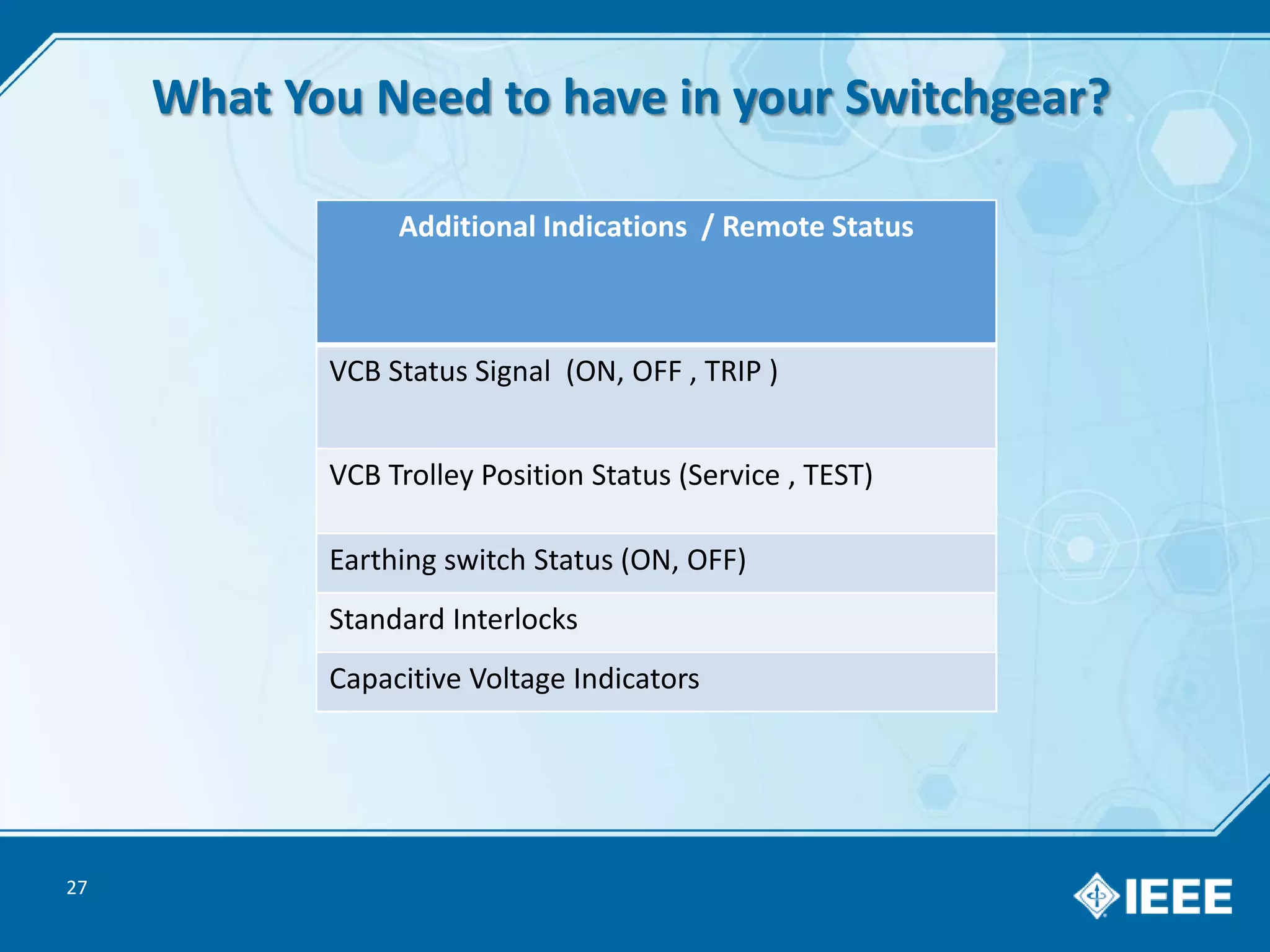

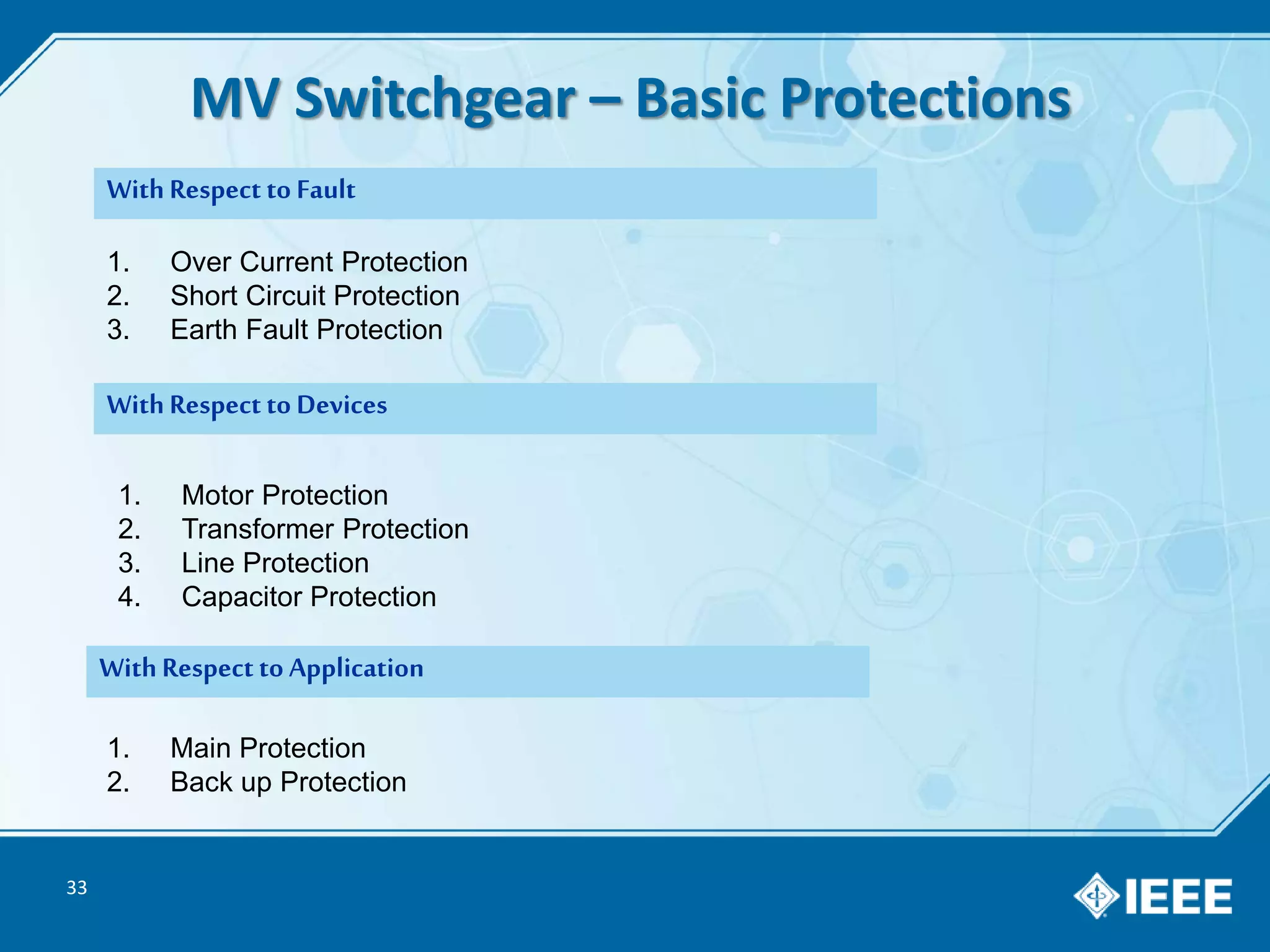

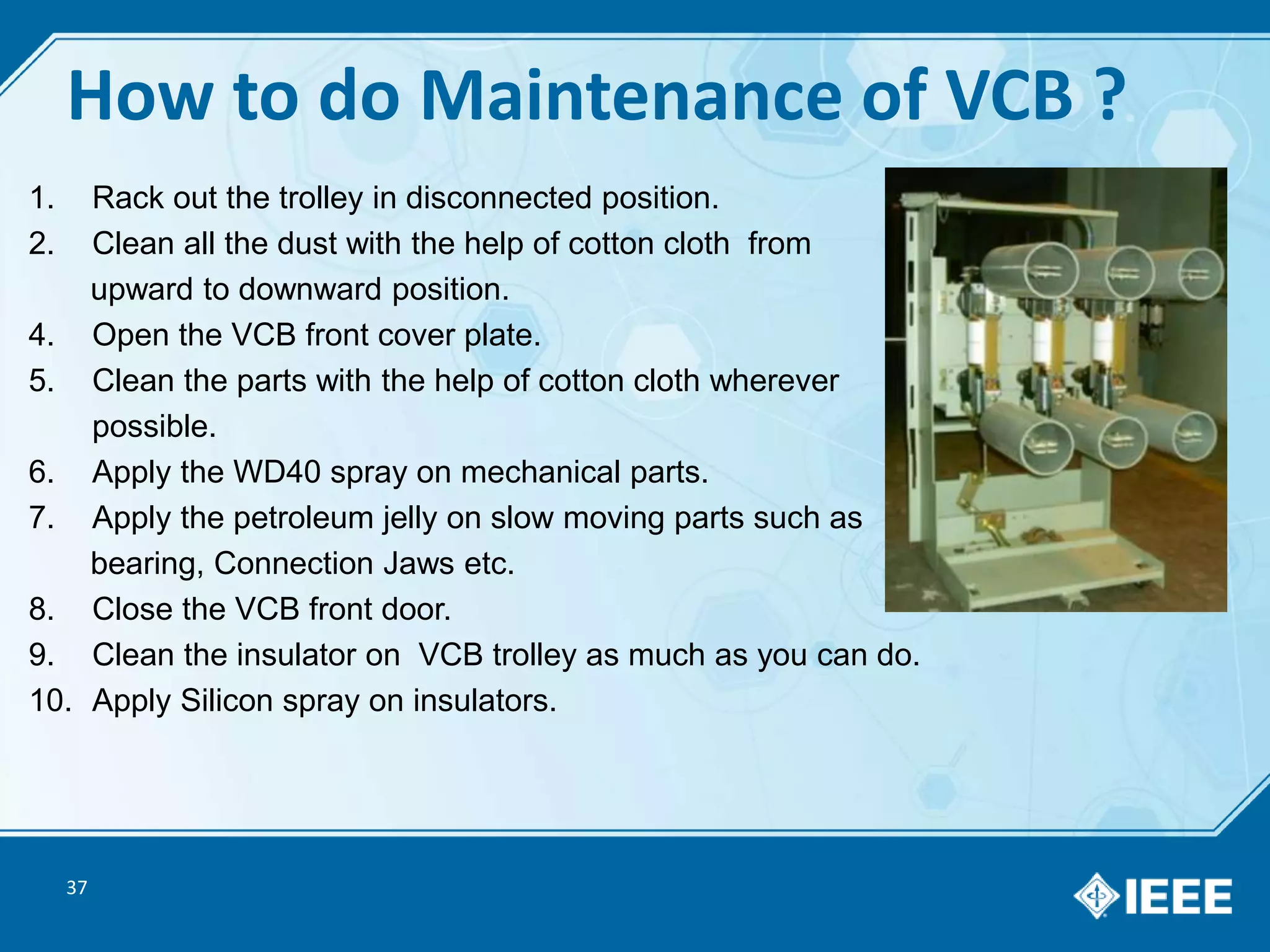

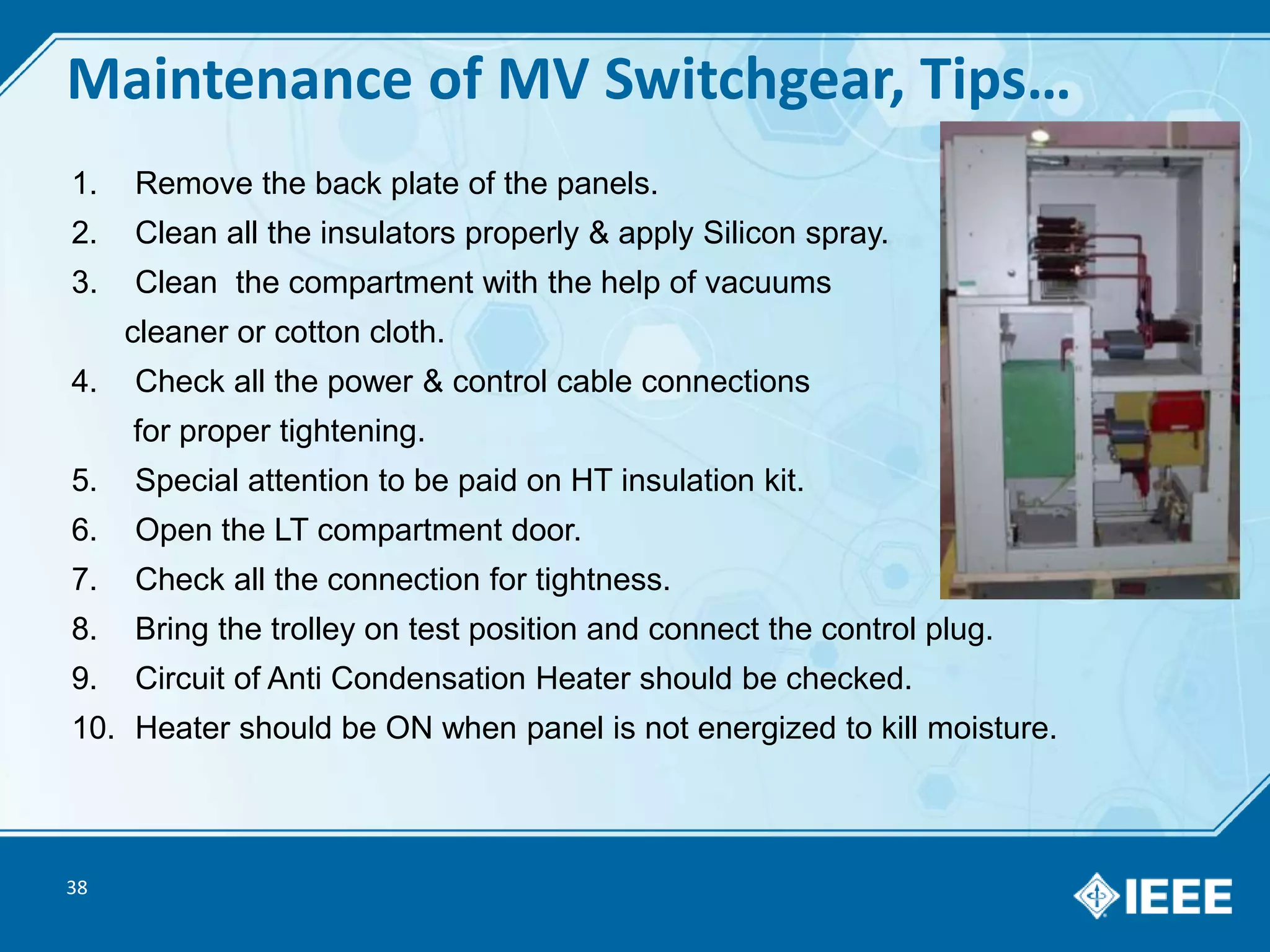

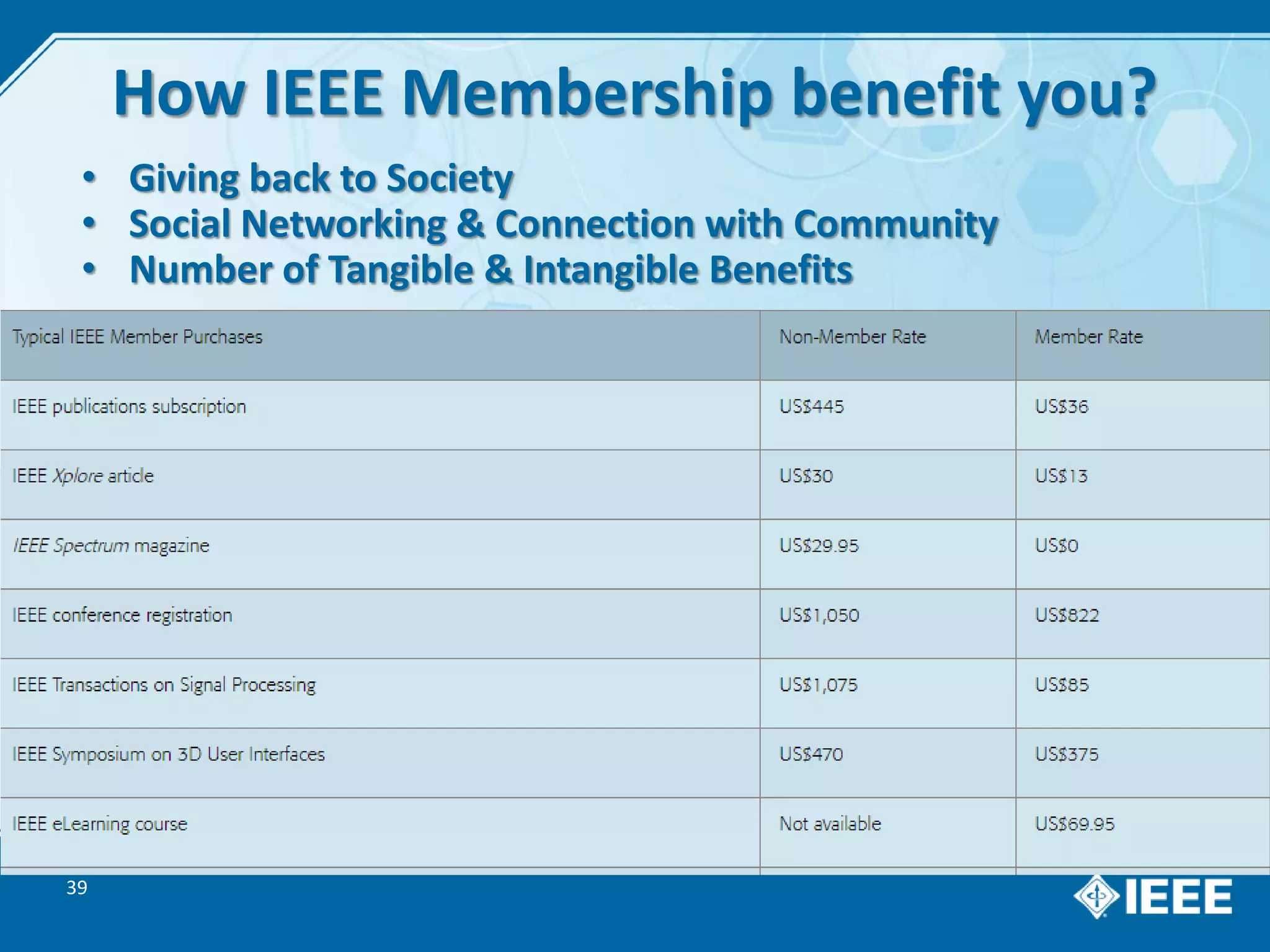

This document provides comprehensive information on medium voltage (MV) switchgear, including types, designs, electrical ratings, testing standards, and essential protective features. It emphasizes the significance of proper installation, maintenance, and protection of electrical equipment to ensure reliability and safety. Additionally, it discusses the benefits of IEEE membership and the associated costs for joining.