- Mechanical Engineering graduate with 10 years of experience in procurement and sourcing roles in industries like earth moving, automotive, and hydraulics.

- Experienced in casting, fabrication, sheet metal processes, cost reduction, negotiation, quality systems and production planning.

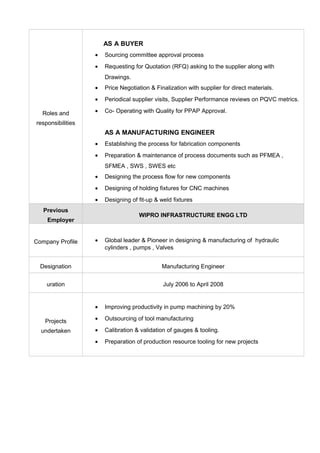

- Currently working as Manager of Sourcing and Purchasing at WABCO India, handling procurement of casting, forging, and sheet metal components.