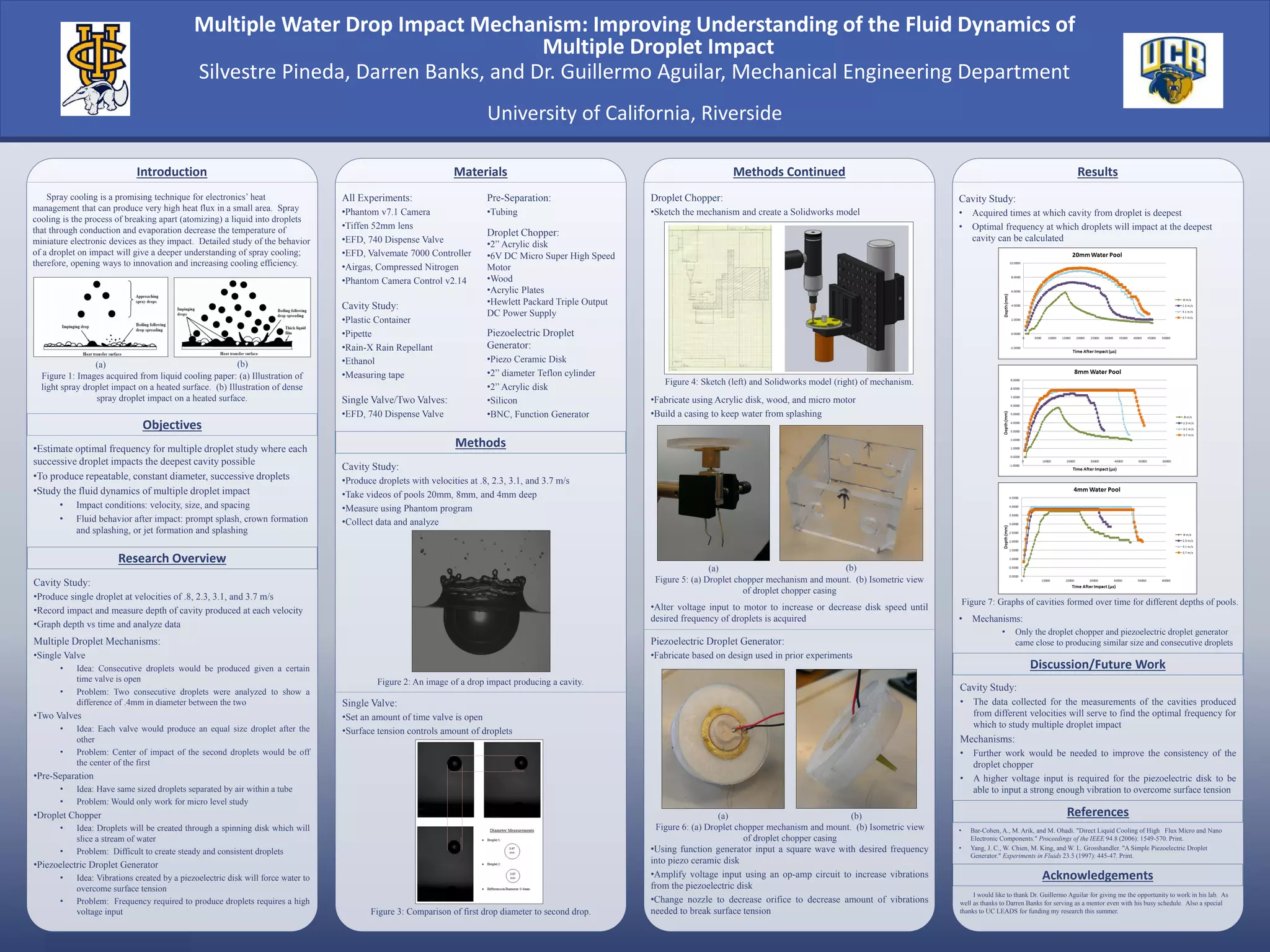

Spray cooling uses atomized liquid droplets to efficiently cool electronics through conduction and evaporation on impact. Studying individual droplet behavior on impact can provide insight into spray cooling dynamics and opportunities for innovation. The document describes experiments to better understand multiple droplet impacts by developing mechanisms to generate consecutive, similarly sized water droplets. Methods tested include single and dual valves, pre-separation in a tube, a droplet chopper, and a piezoelectric droplet generator. Future work involves estimating optimal frequencies for multiple droplet studies and producing repeatable, consistently sized successive droplets to analyze fluid behavior after impact.