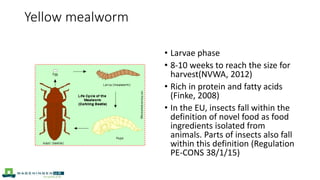

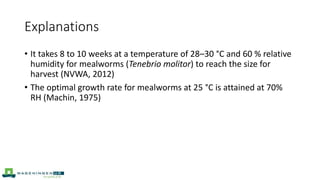

This document discusses a study assessing the potential for large scale production of insects, specifically focusing on the quality attributes that can influence large scale production of Yellow mealworms (Tenebrio molitor).

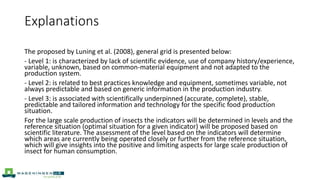

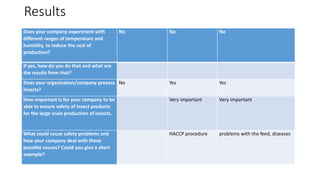

[1] The study aims to highlight key factors relevant to upscaling insect production, how they contribute to large scale production, and how these factors influence quality outcomes related to safety and nutrition. The study examines technological and managerial requirements for insect mass production and rearing conditions important for upscaling production.

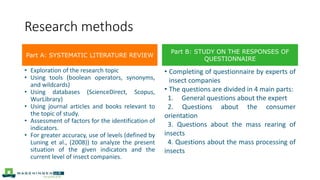

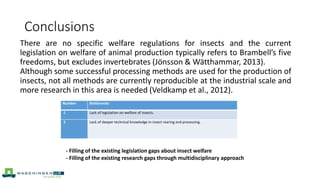

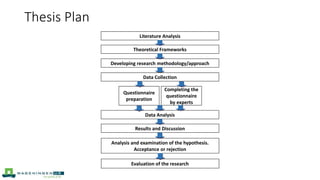

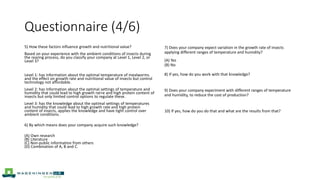

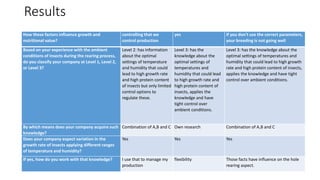

[2] A literature review and questionnaire were used to analyze diverse technological and managerial aspects that can influence quality outcomes. Results found that insect rearing companies have individually developed welfare practices but are hesitant to share