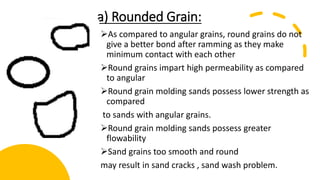

The document discusses the properties and ingredients of molding sand used in casting, focusing on permanent and temporary molds. It describes various types of sands, binders, additives, and their effects on mold properties like flowability, green strength, and refractoriness. Additionally, it differentiates between facing sand and backing sand, emphasizing their specific roles in mold creation and performance.