This document describes the design and development of a vision add-on for a modular self-reconfigurable robot system called HiGen. The add-on aims to provide sensing capabilities to improve the robot's ability to interact with its environment and perform tasks. The document outlines the hardware and software design of the add-on, which includes a pan-tilt unit, camera, and microcontroller. Experiments are conducted to test the add-on's ability to track and follow targets. The design lays the foundation for further development of software and control to fully integrate the add-on with the HiGen robot.

![X

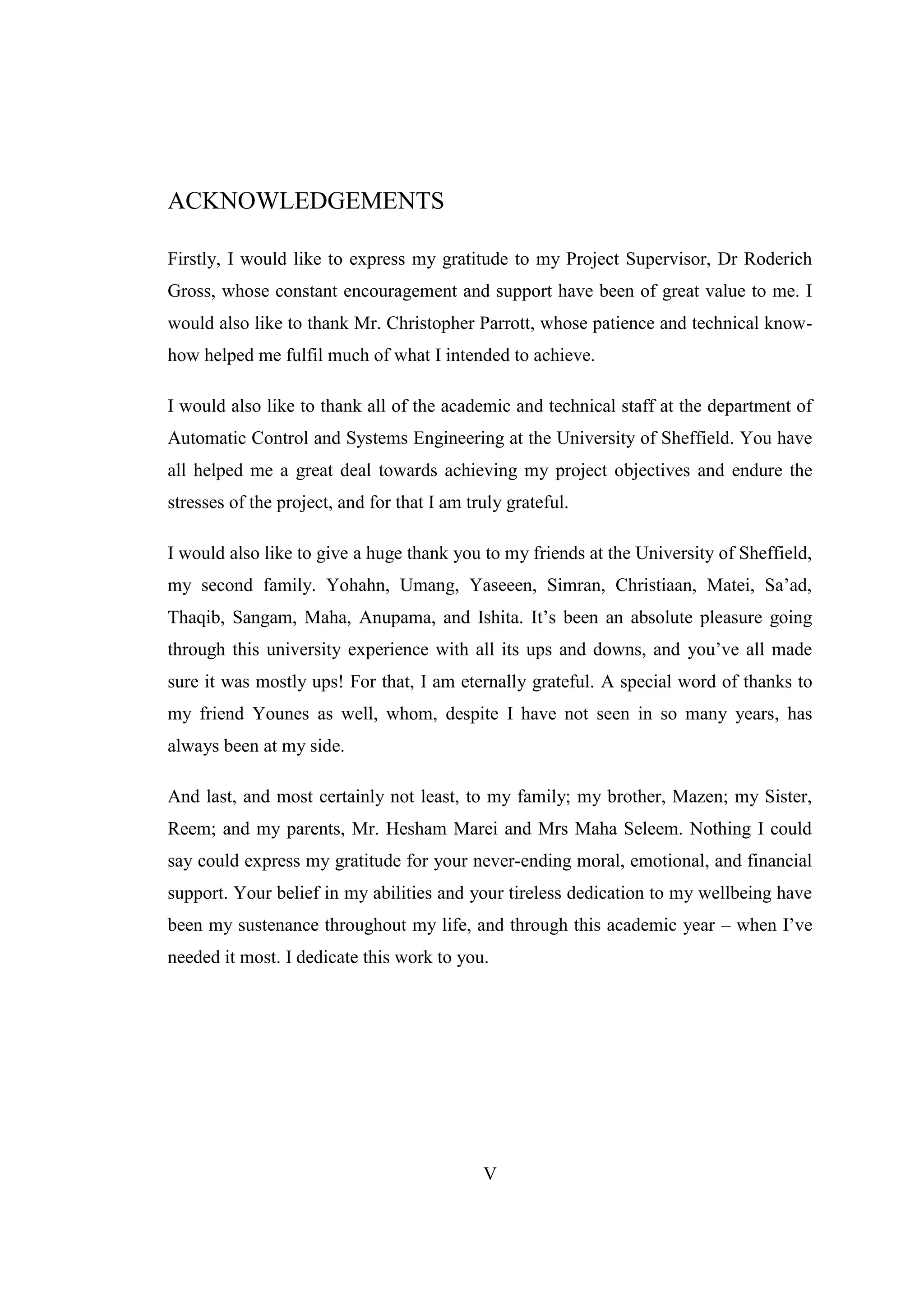

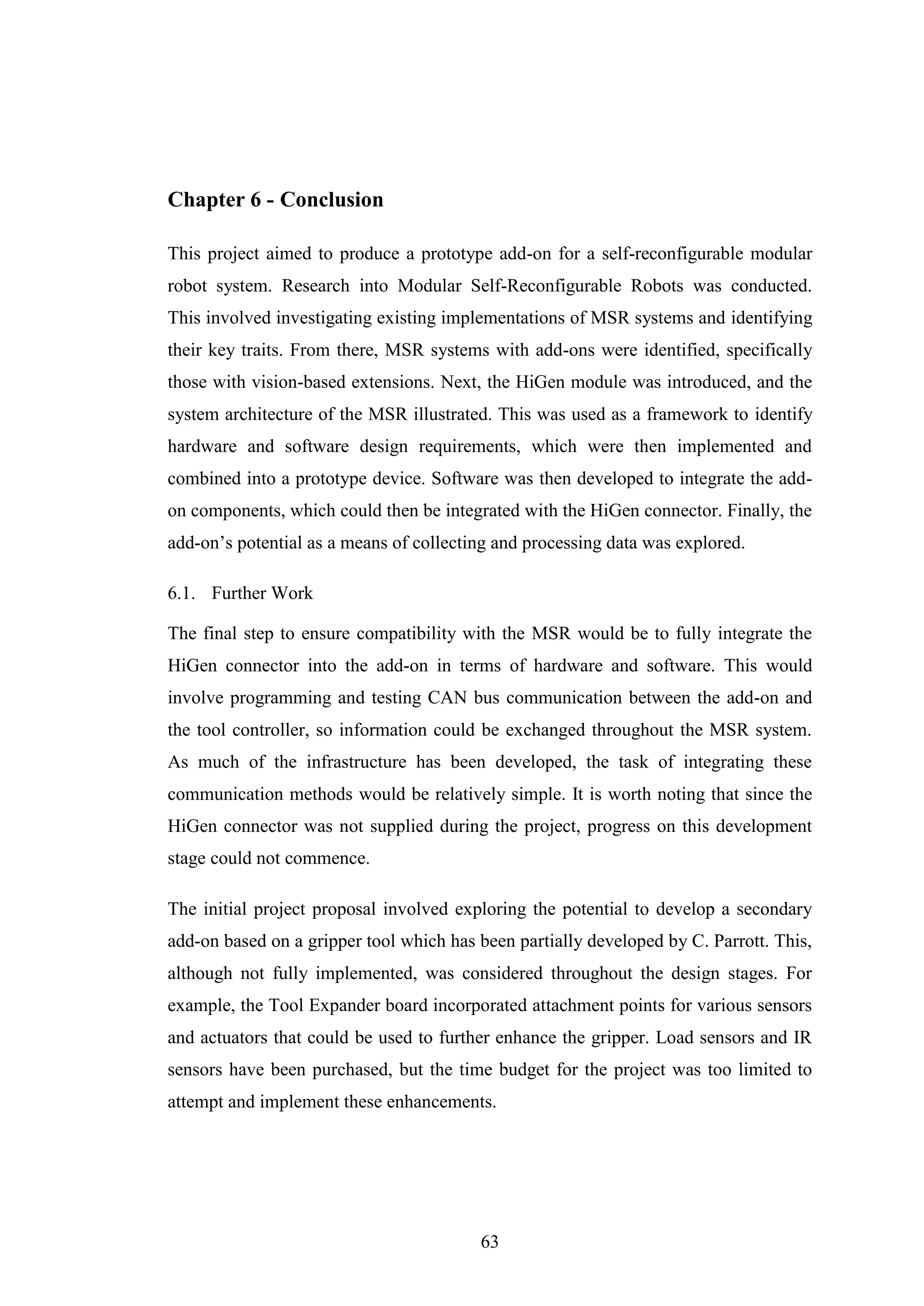

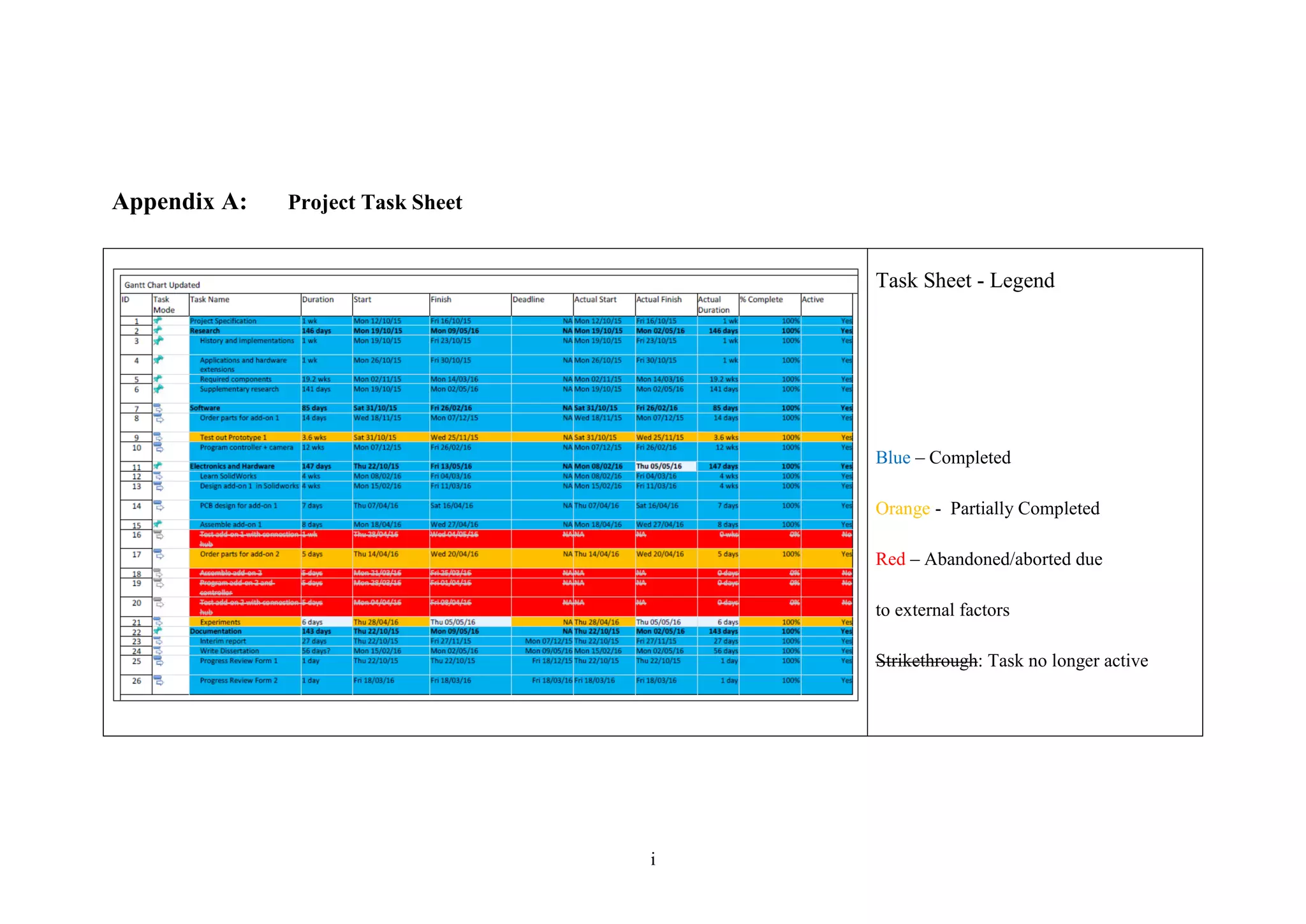

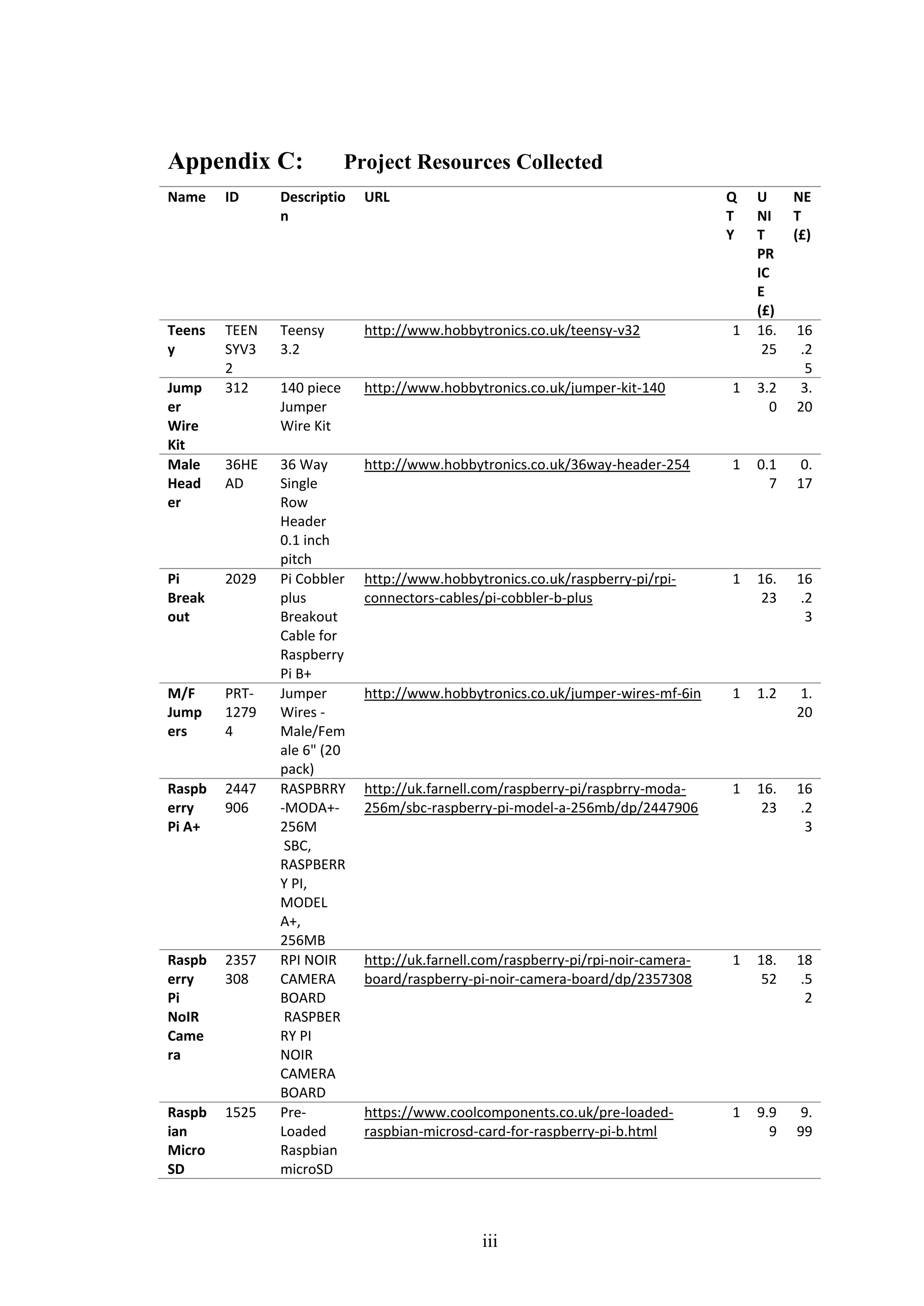

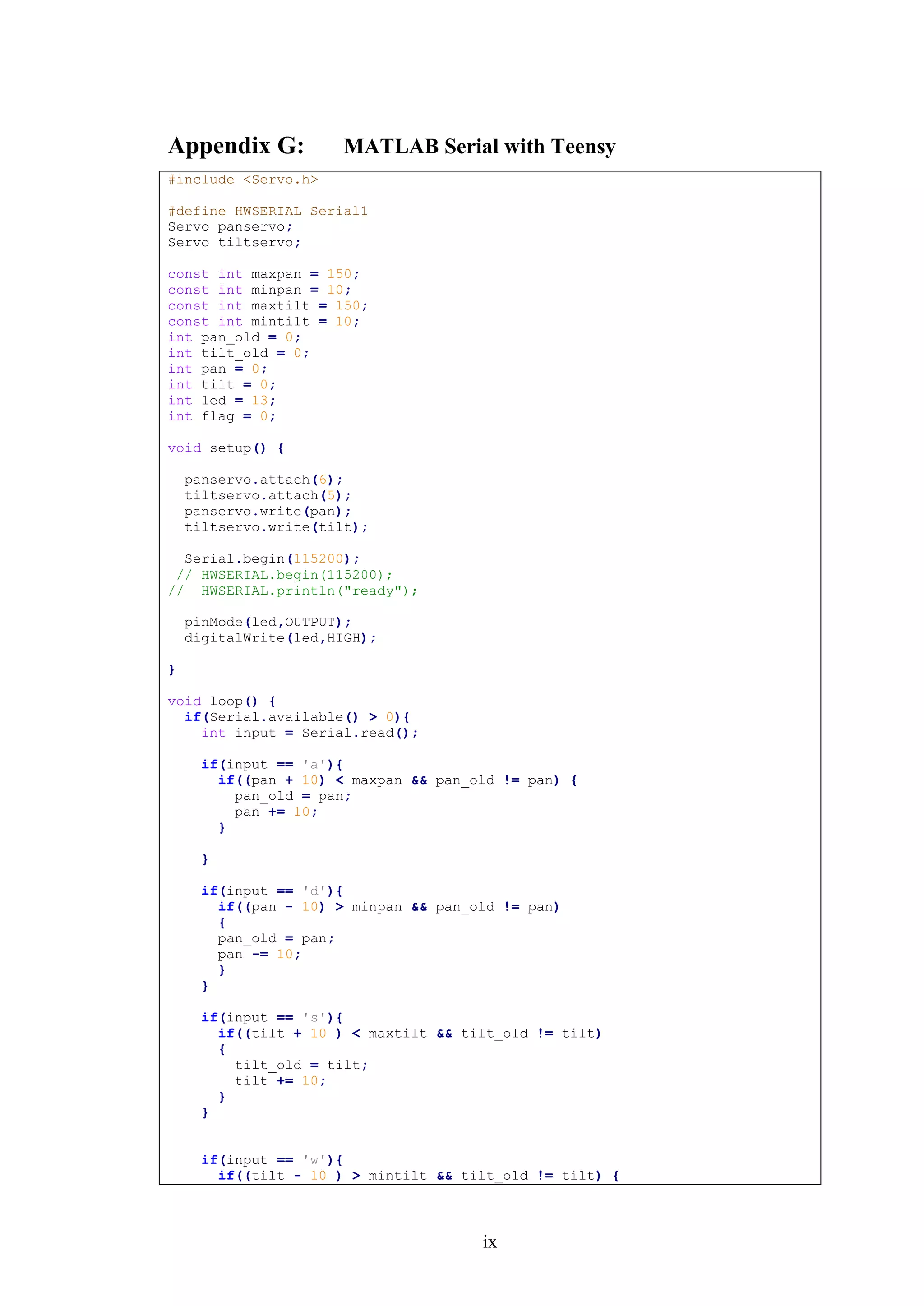

LIST OF FIGURES

Figure 1: the ATRON self-reconfigurable robot combined into a snake configuration

(left), a vehicle-like configuration (right), and an intermediate configuration (back).

Printed from [3]............................................................................................................11

Figure 2 showing the components involved in robot design and their interaction.

Adapted from [8]..........................................................................................................12

Figure 3(a) and (b): standalone HiGen connector module (left) [20] and HiGen

modules on the self-reconfigurable modular robot (right) [28]. Printed with

permission from C. Parrott, 2014.................................................................................21

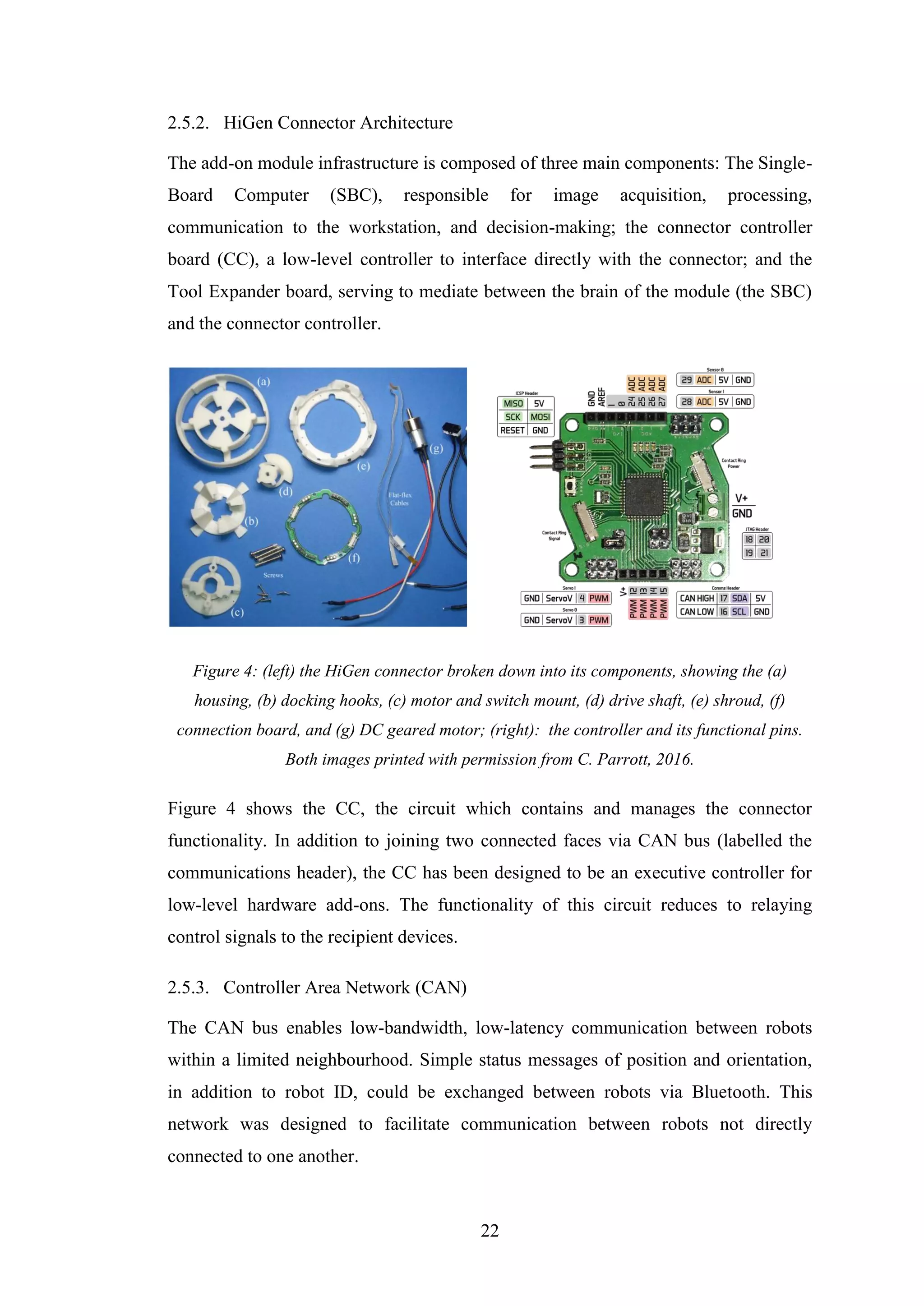

Figure 4: (left) the HiGen connector broken down into its components, showing the

(a) housing, (b) docking hooks, (c) motor and switch mount, (d) drive shaft, (e)

shroud, (f) connection board, and (g) DC geared motor; (right): the controller and its

functional pins. Both images printed with permission from C. Parrott, 2016. ............22

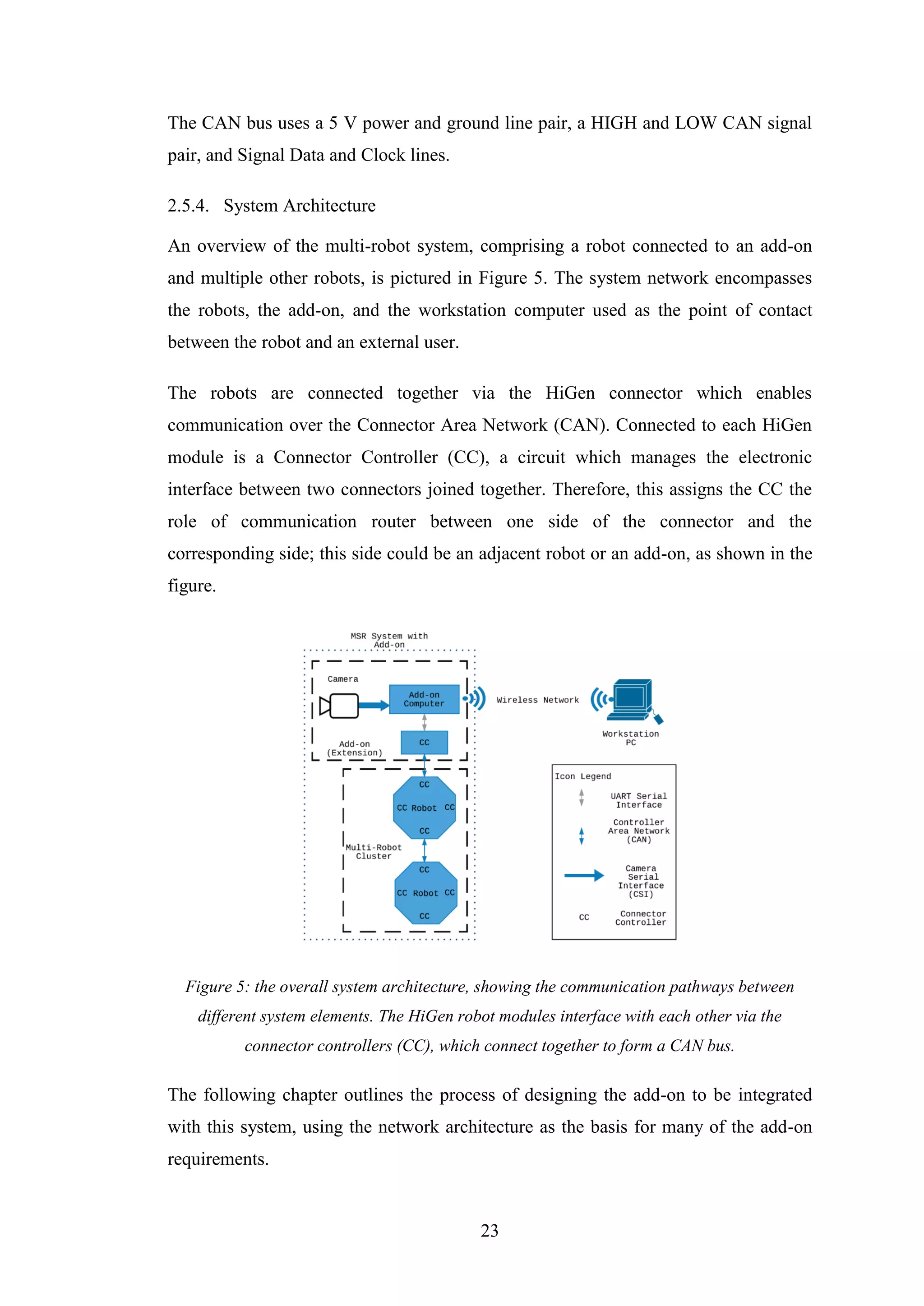

Figure 5: the overall system architecture, showing the communication pathways

between different system elements. The HiGen robot modules interface with each

other via the connector controllers (CC), which connect together to form a CAN bus.

......................................................................................................................................23

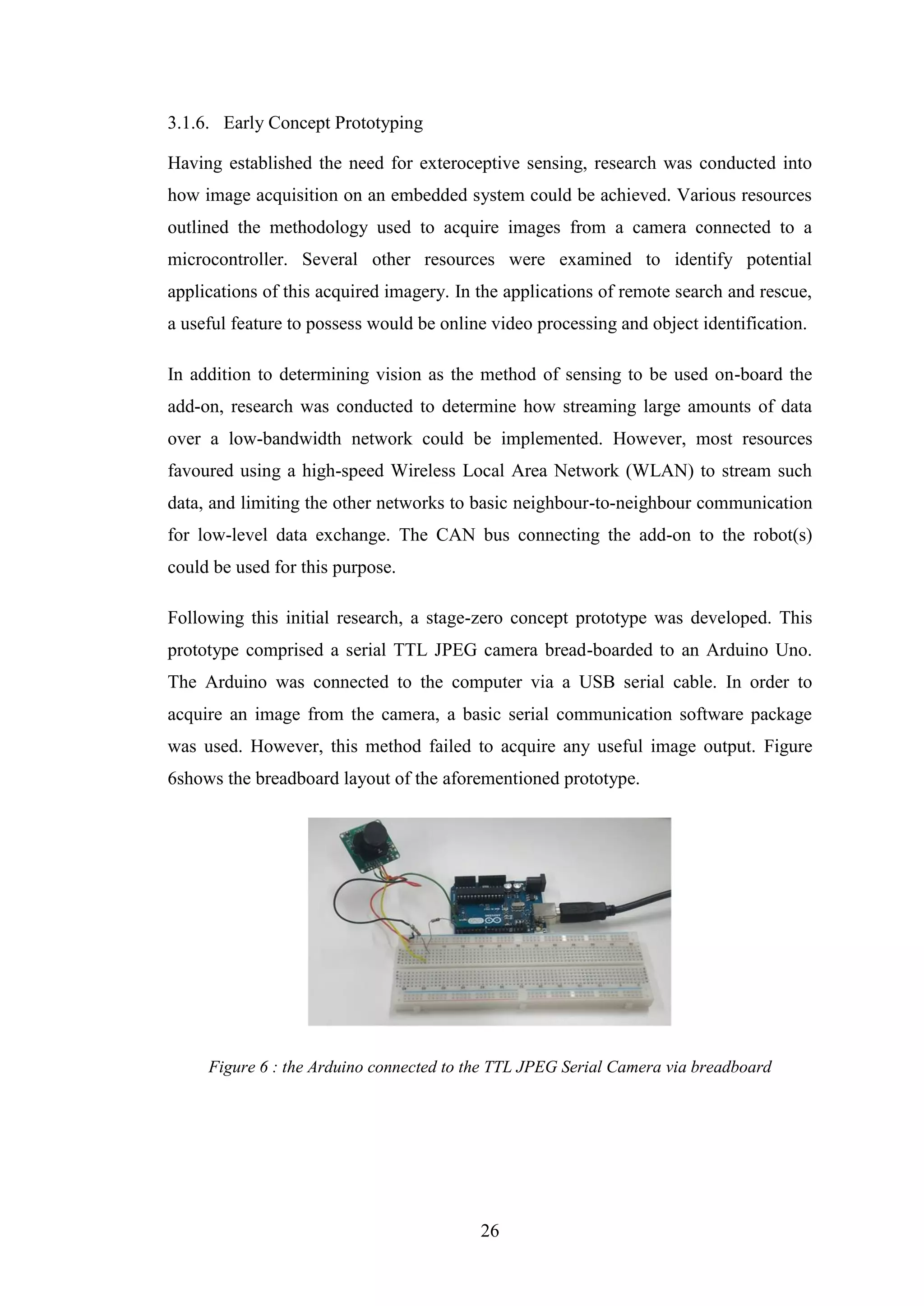

Figure 6 : the Arduino connected to the TTL JPEG Serial Camera via breadboard ...26

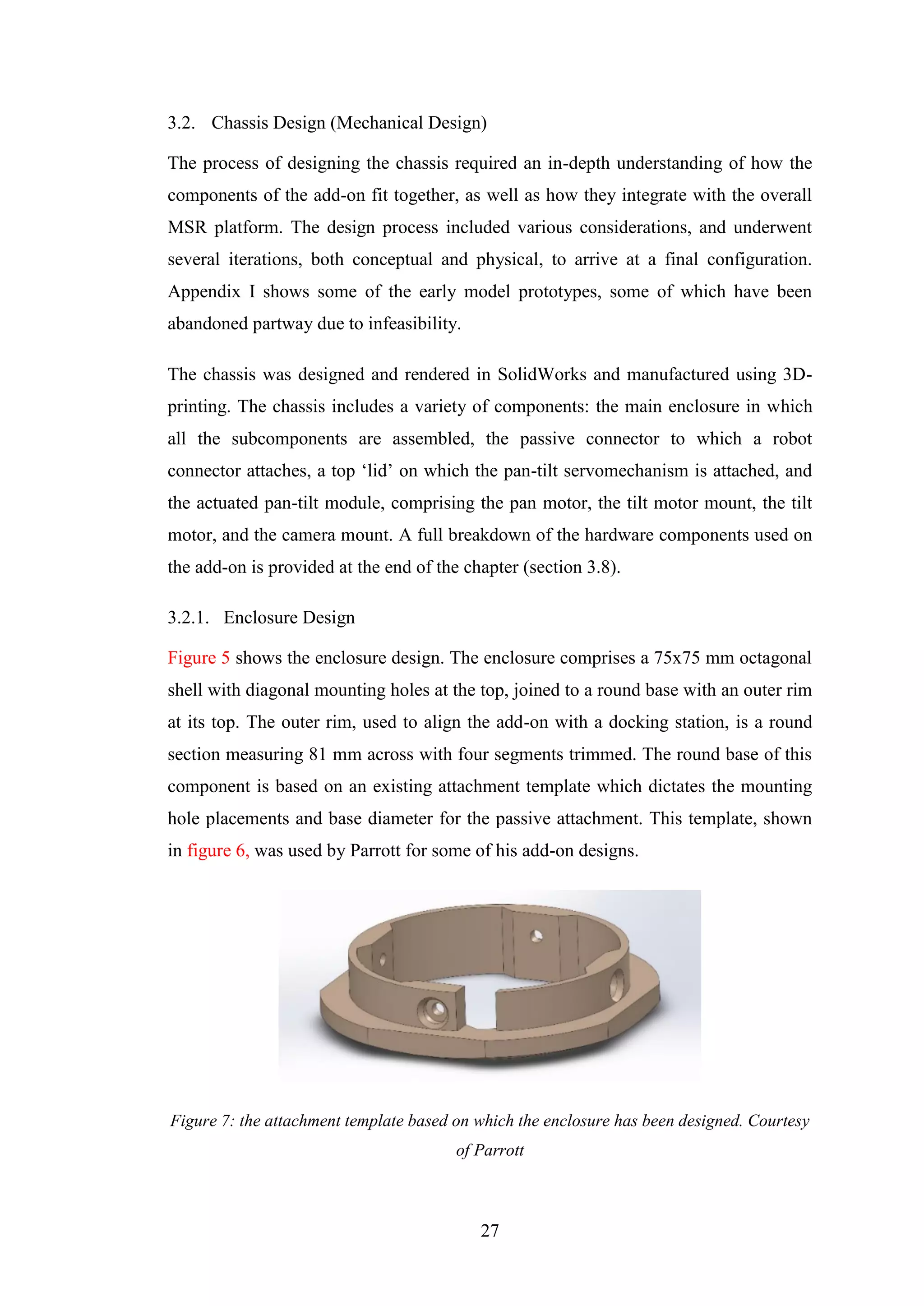

Figure 7: the attachment template based on which the enclosure has been designed.

Courtesy of Parrott.......................................................................................................27

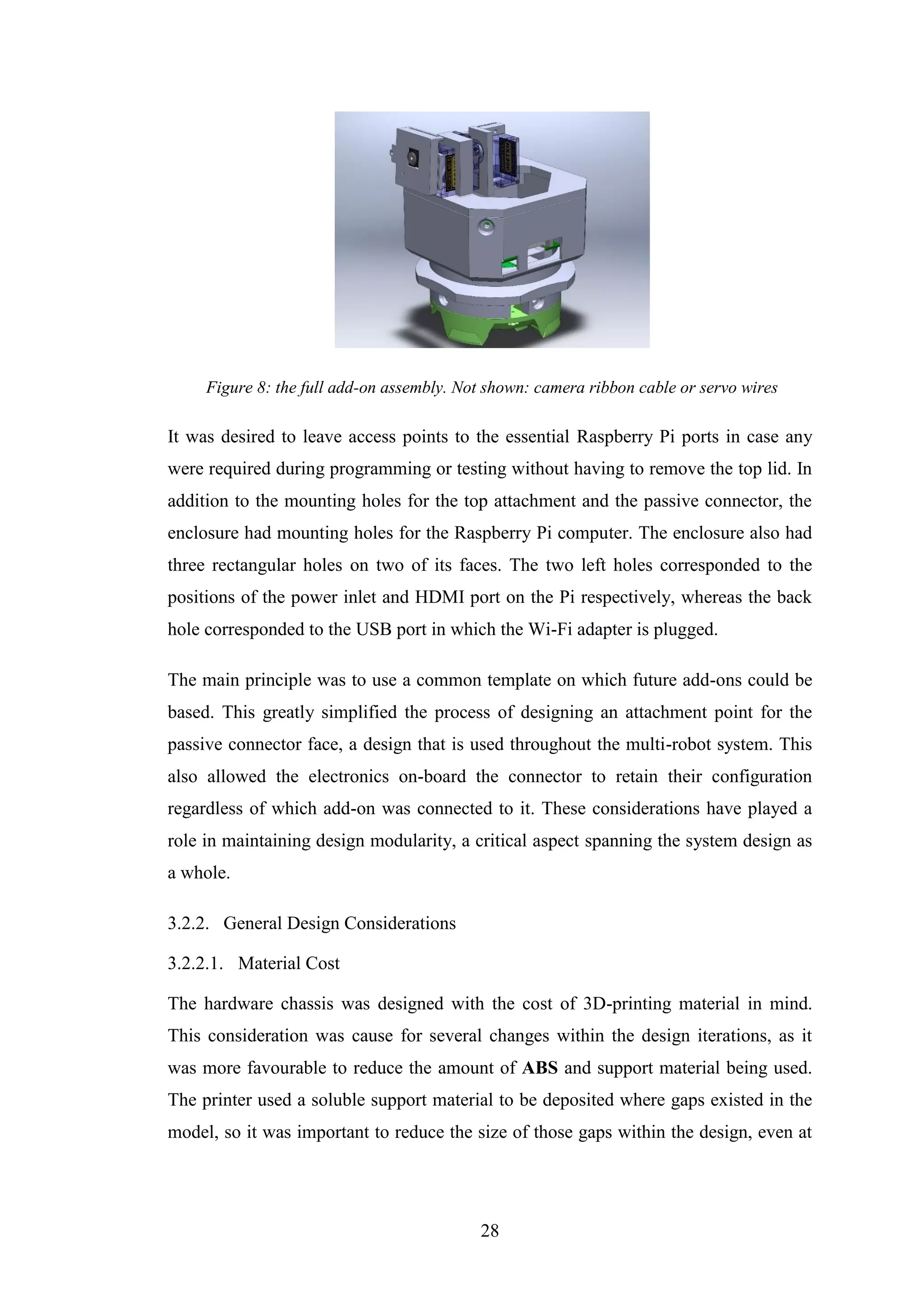

Figure 8: the full add-on assembly. Not shown: camera ribbon cable or servo wires.28

Figure 9: the pan/tilt mechanism for two use cases: front attachment (left), and side

attachment (right).........................................................................................................30

Figure 10: pan/tilt motion arcs, showing a range of approximately ±180° .................31](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-10-2048.jpg)

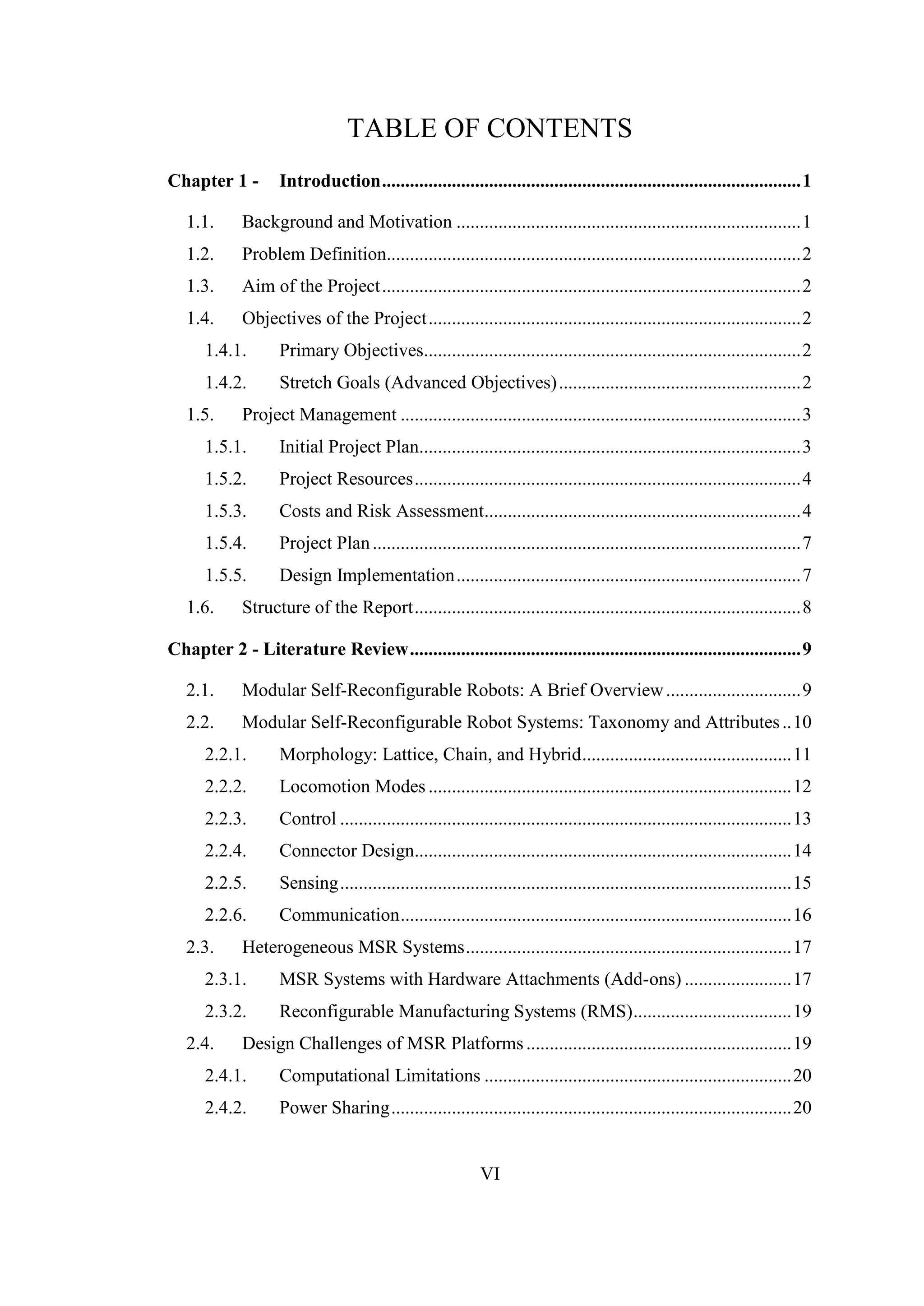

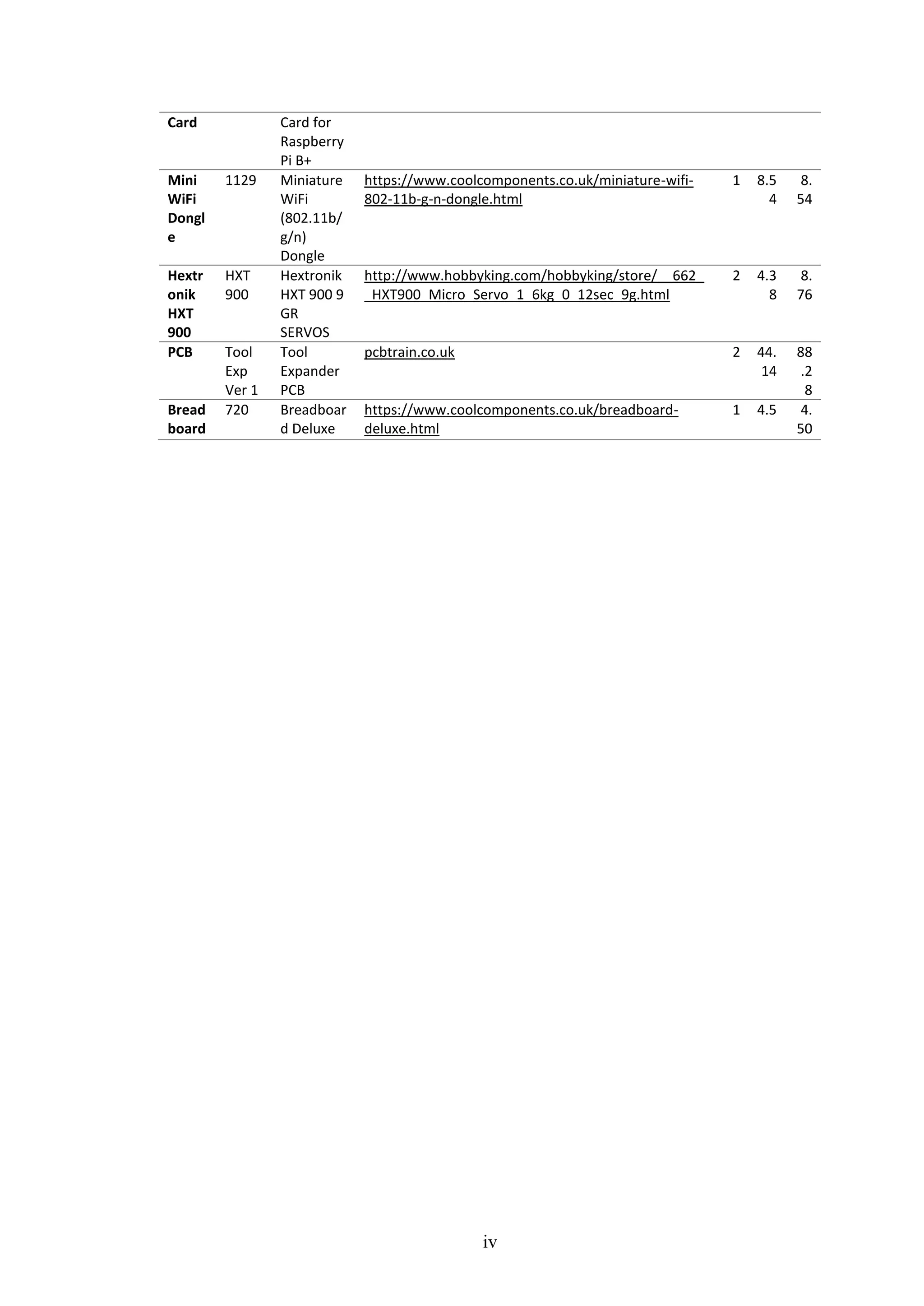

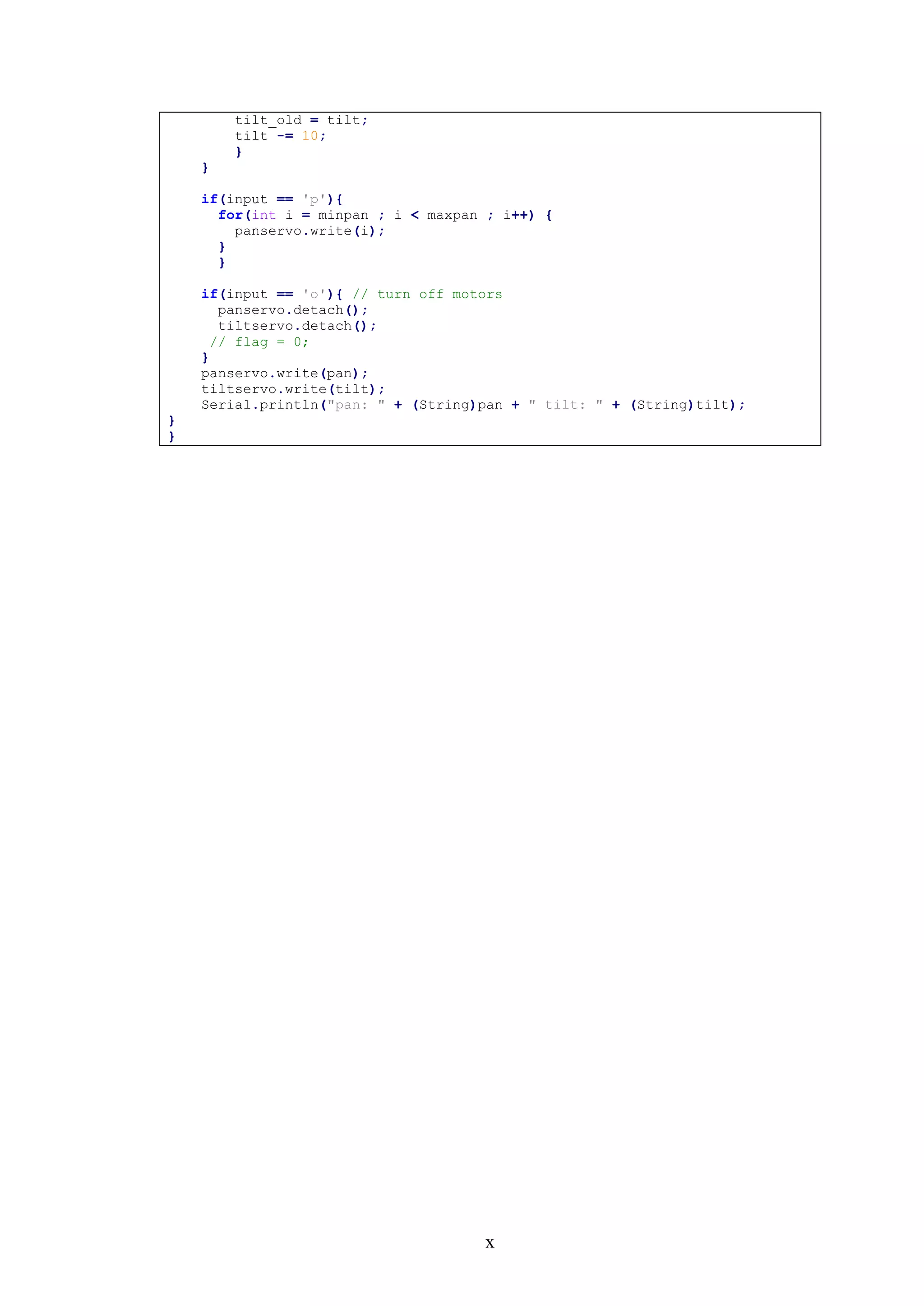

![XI

Figure 11: four different single-board computers; Raspberry Pi 2 (left, back); ODroid

C1 (right, back); HummingBoard (left, front); MIPS Creator Ci20 (right, front).

Reproduced from [30]..................................................................................................31

Figure 12: (left) Raspberry Pi NoIR Camera. Retrieved from [31]; (centre) Teensy 3.2

LC (Low Cost). Retrieved from [32]; (right): Raspberry Pi Model A+. Retrieved from

[33]...............................................................................................................................33

Figure 13: an n+4-bit 'word' transmitted over UART serial, showing the start bit

(StrB), data bits (DB01-DBn), parity bit (PB), and stop bits (StpB)...........................35

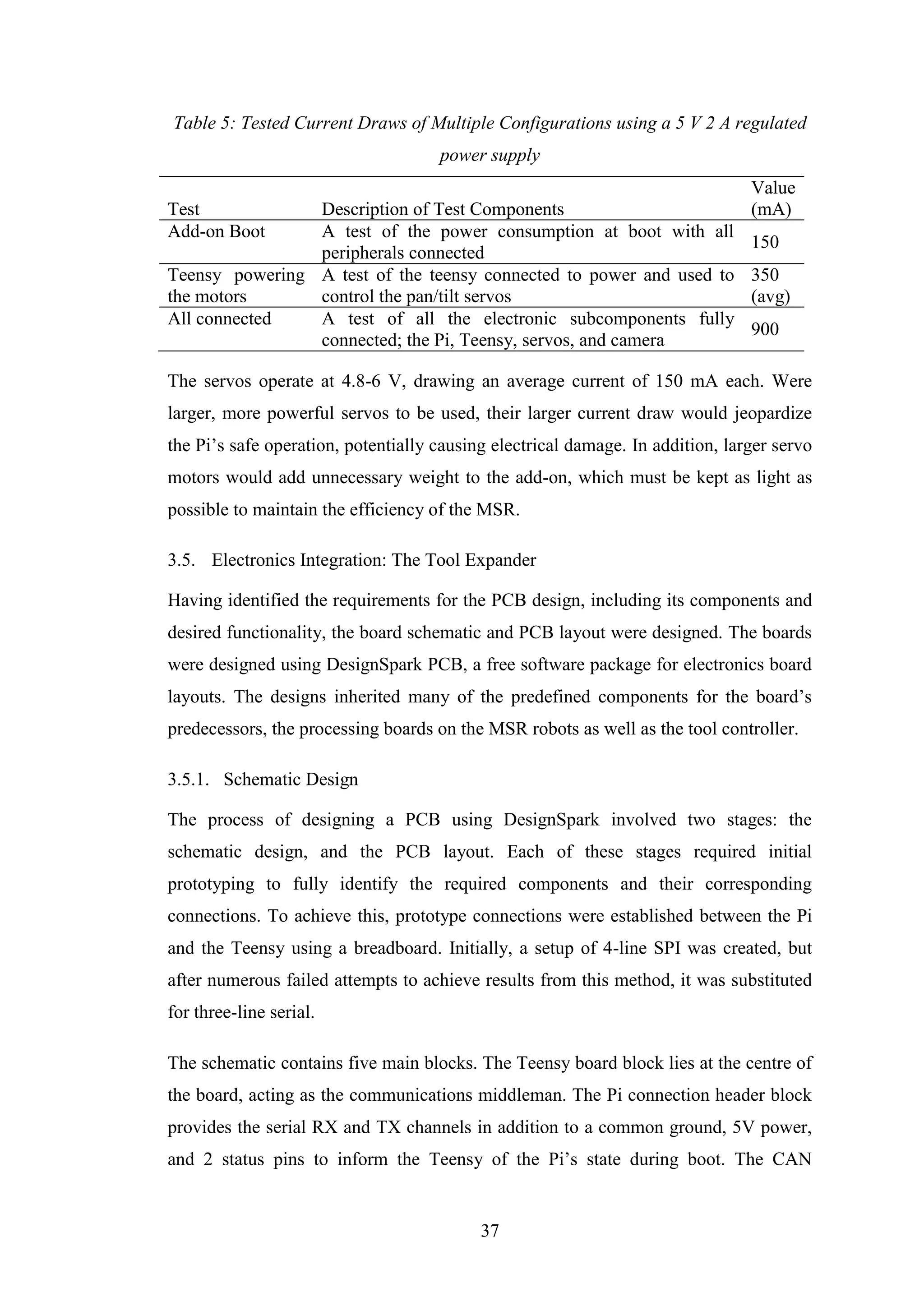

Figure 14: schematic diagram for the Tool Expander PCB.........................................39

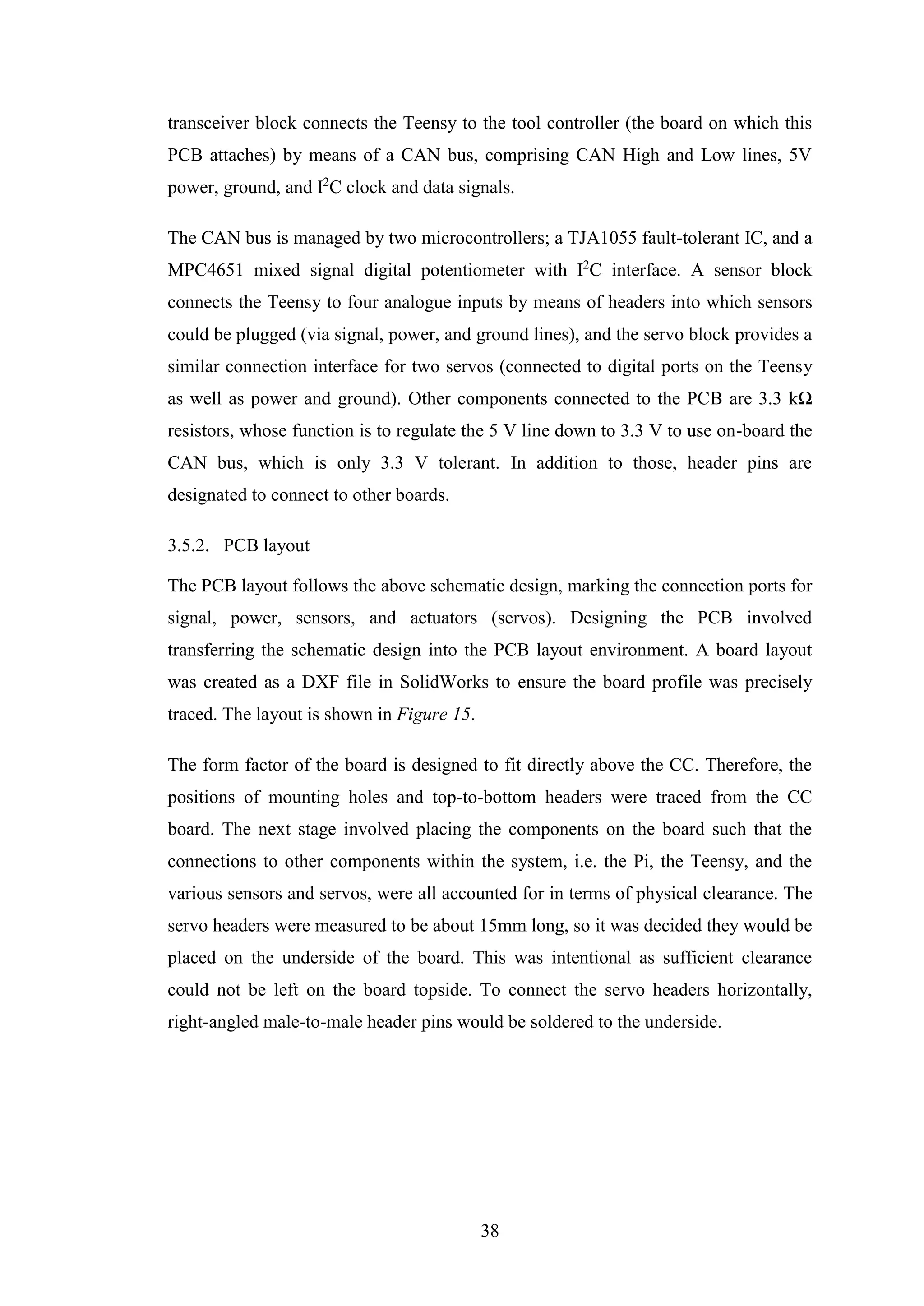

Figure 15: the Tool Expander PCB design..................................................................40

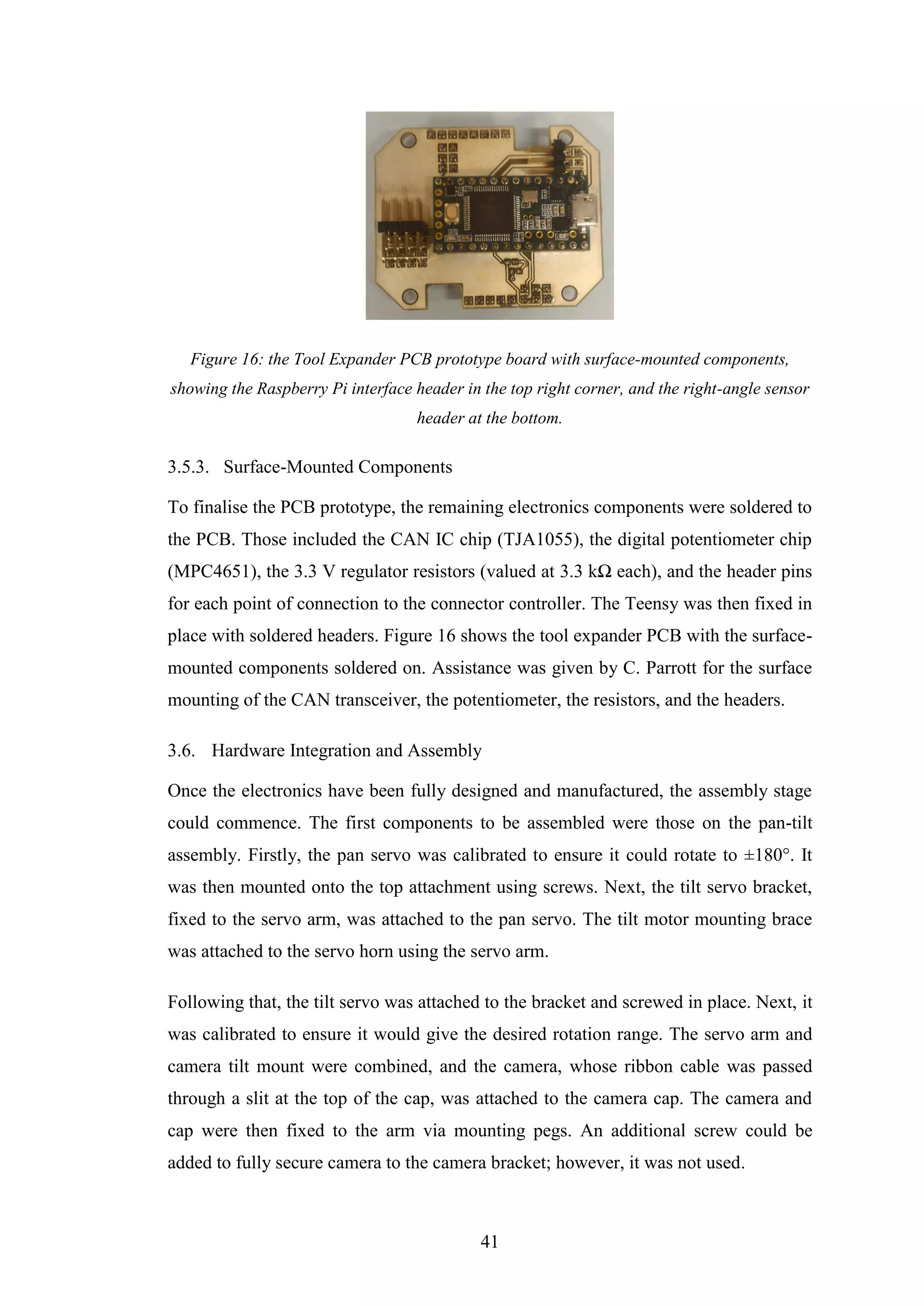

Figure 16: the Tool Expander PCB prototype board with surface-mounted

components, showing the Raspberry Pi interface header in the top right corner, and

the right-angle sensor header at the bottom. ................................................................41

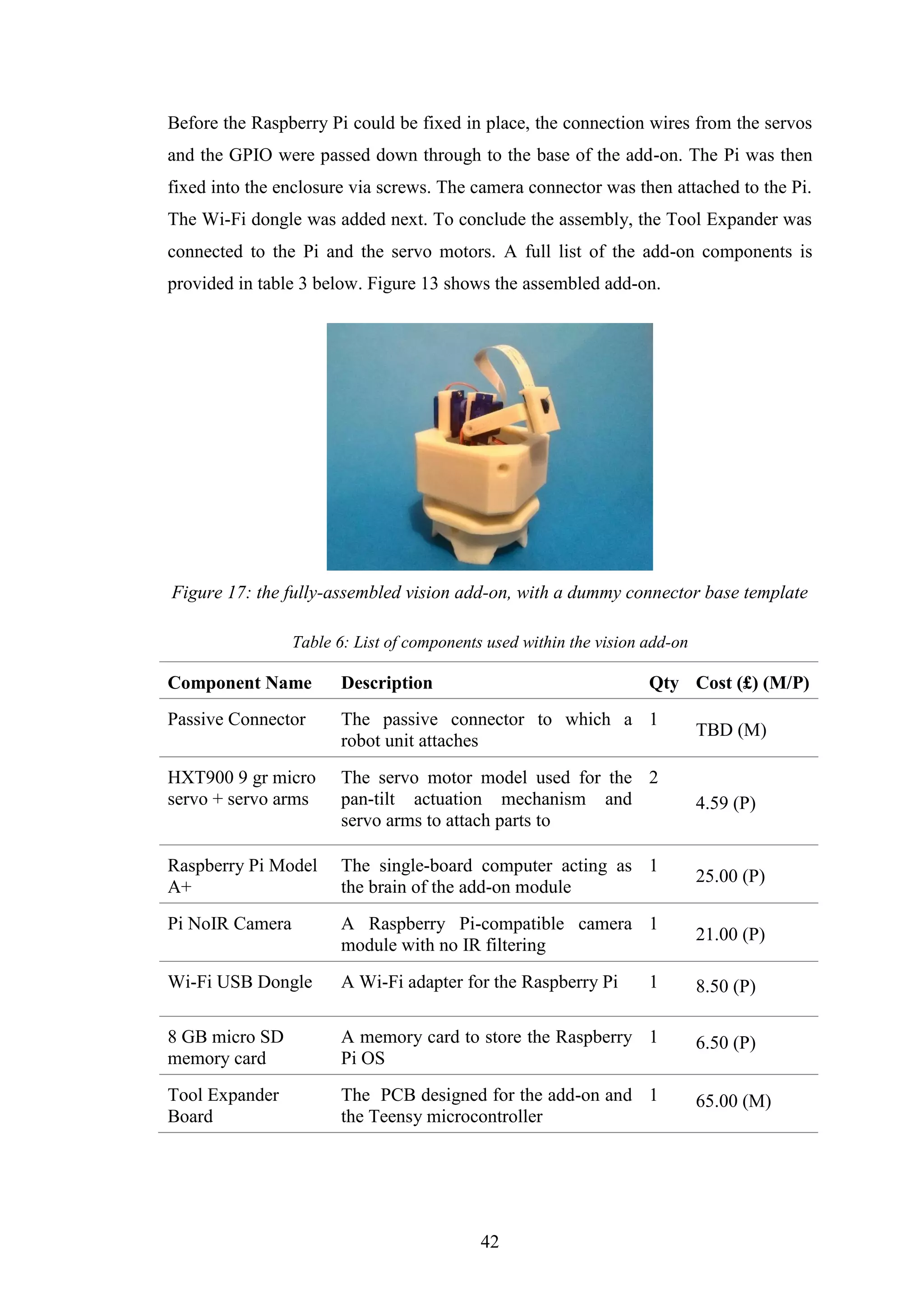

Figure 17: the fully-assembled vision add-on, with a dummy connector base template

......................................................................................................................................42

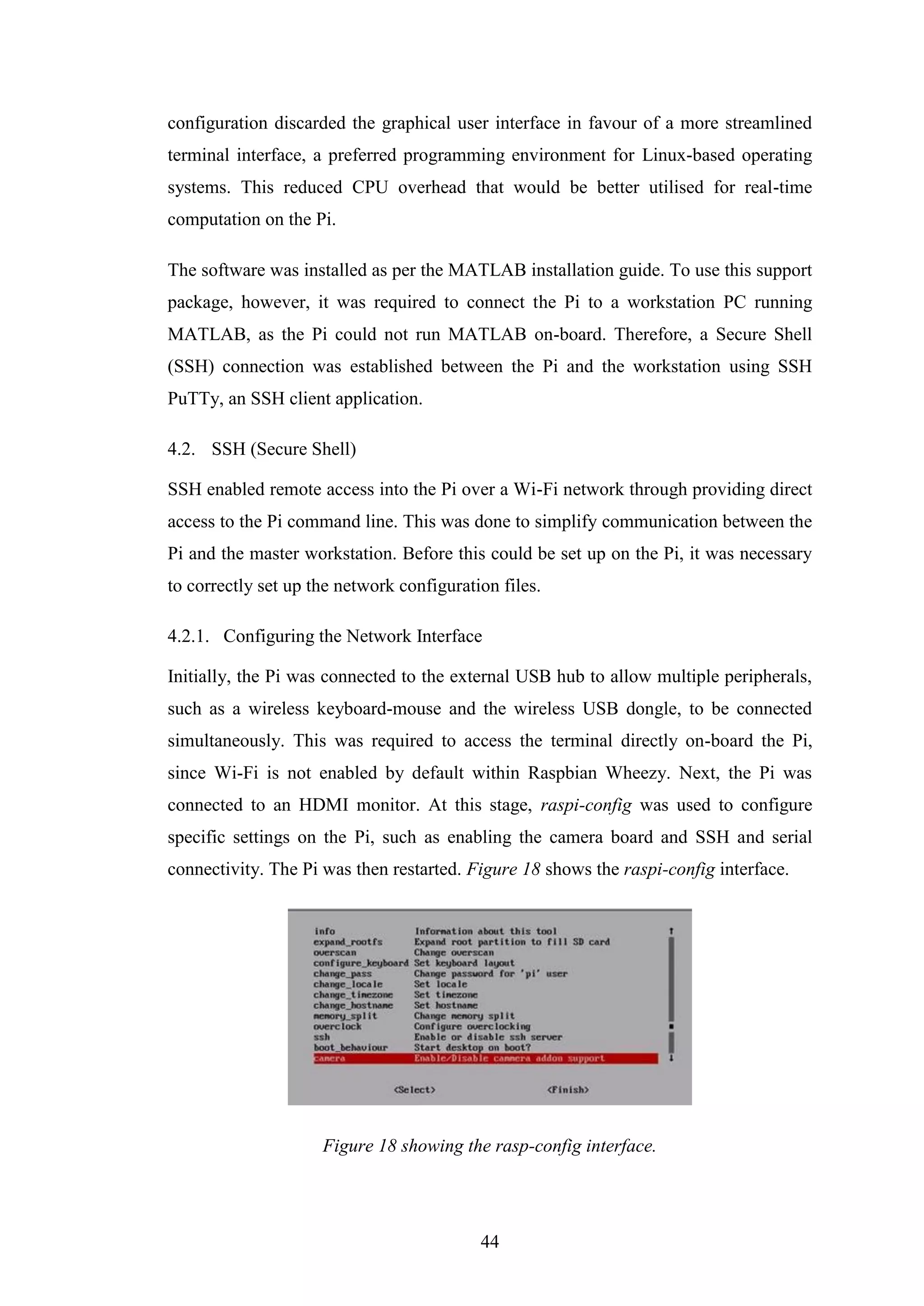

Figure 18 showing the rasp-config interface...............................................................44

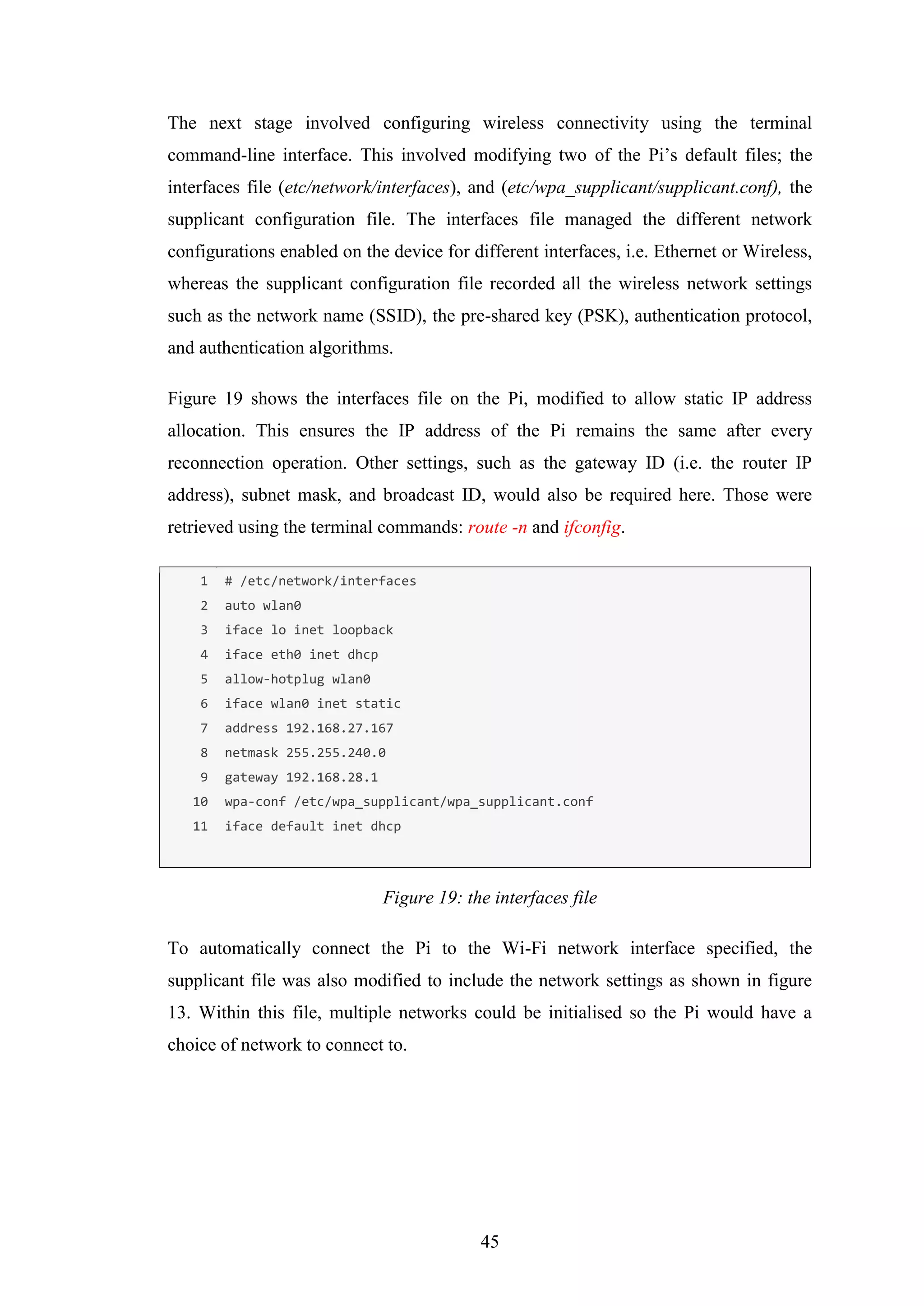

Figure 19: the interfaces file........................................................................................45

Figure 20: the supplicant configuration file................................................................46

Figure 21 showing the basic initialisation function for a Raspberry Pi board...........46

Figure 22 showing the cameraboard initialisation command using the board name

and resolution arguments (top) and the command line output (bottom) .....................47

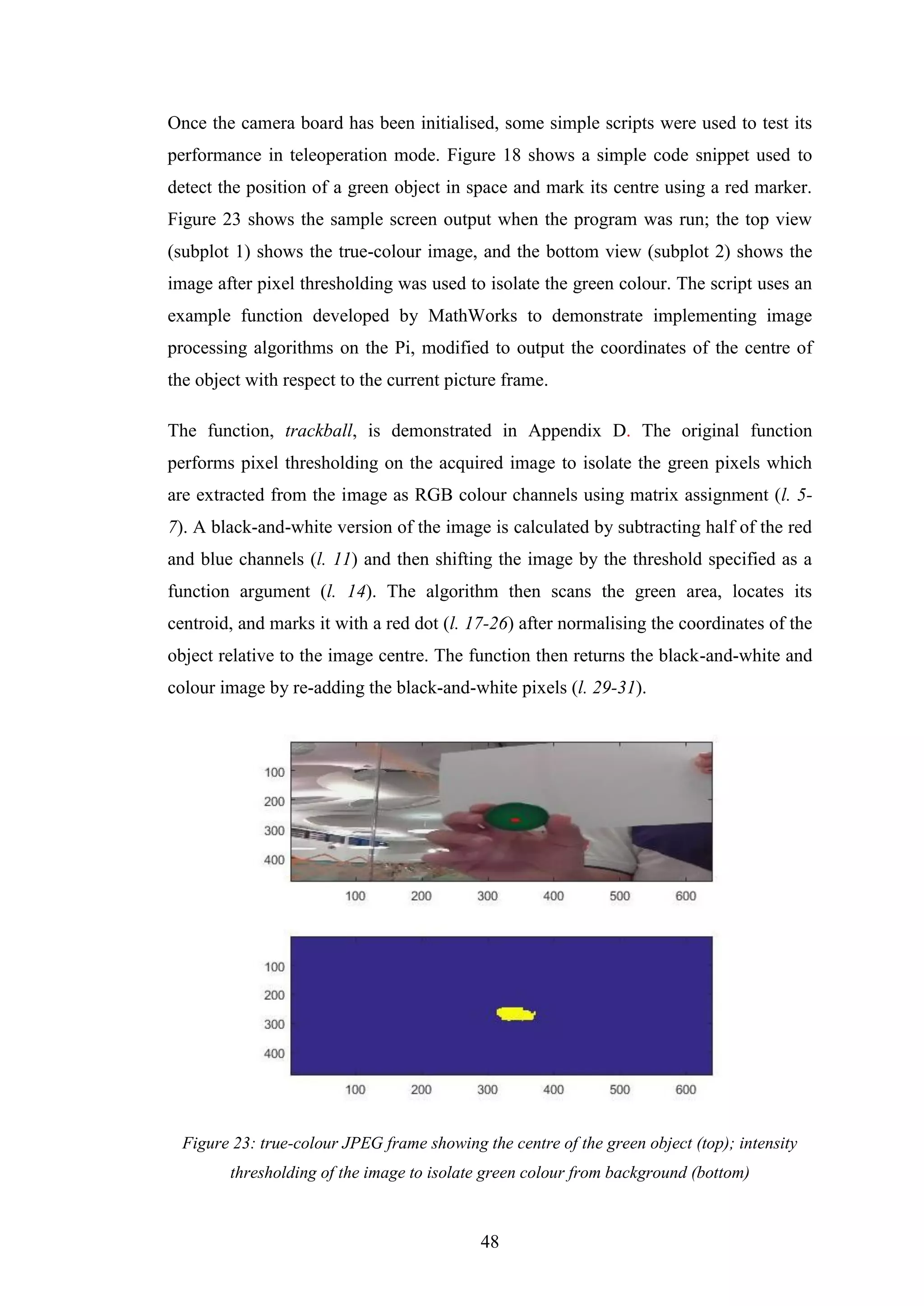

Figure 23: true-colour JPEG frame showing the centre of the green object (top);

intensity thresholding of the image to isolate green colour from background (bottom)

......................................................................................................................................48](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-11-2048.jpg)

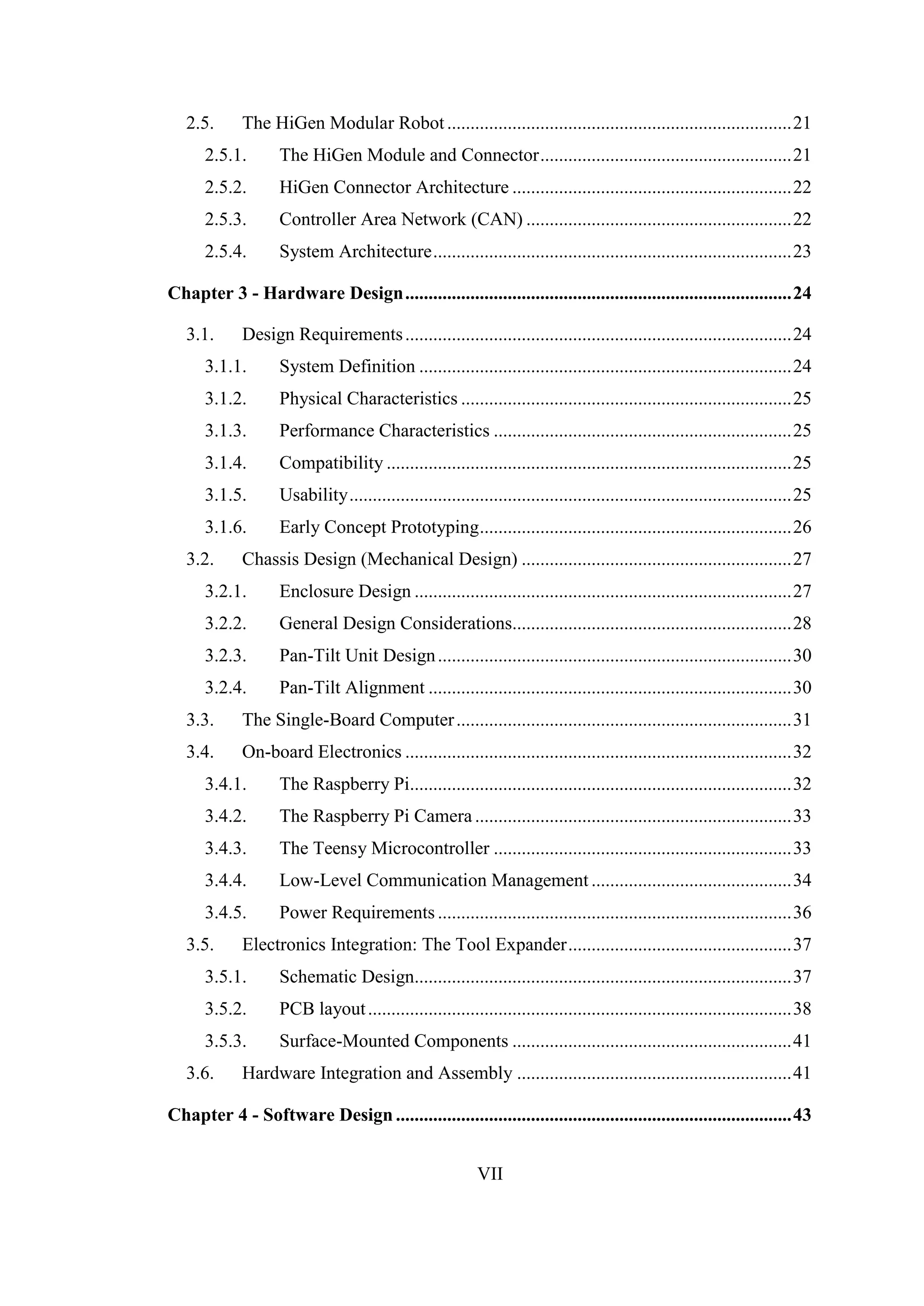

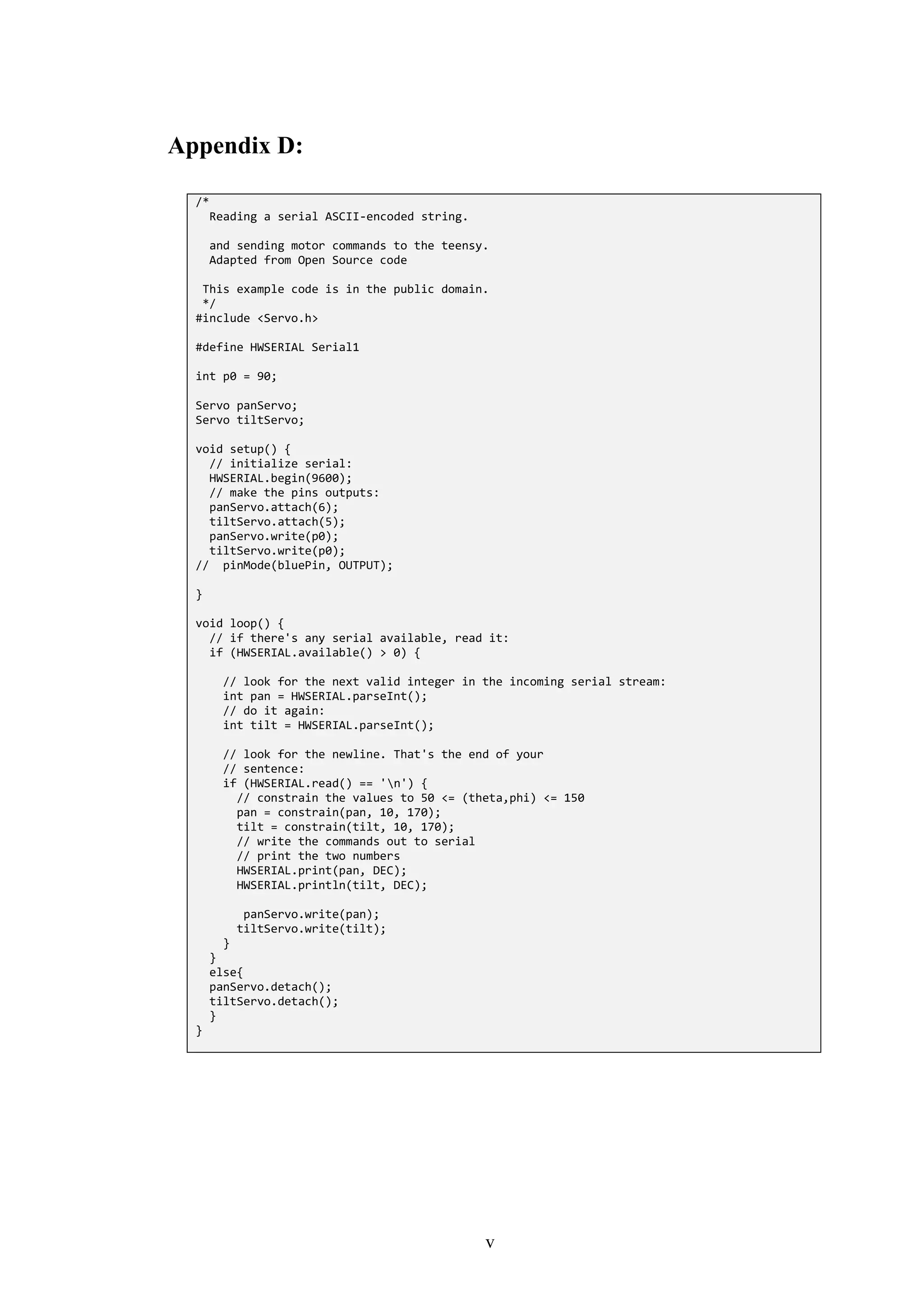

![XII

Figure 24: sample code that uses the trackball algorithm to track the position of the

green object..................................................................................................................49

Figure 25: serial device initialisation command; input arguments: host device name

(Raspberry Pi), serial port address, and baud rate .......................................................49

Figure 26: MiniCom used to input values to the serial port via SSH (left) and the

Arduino serial monitor echoing the data read (right)...................................................50

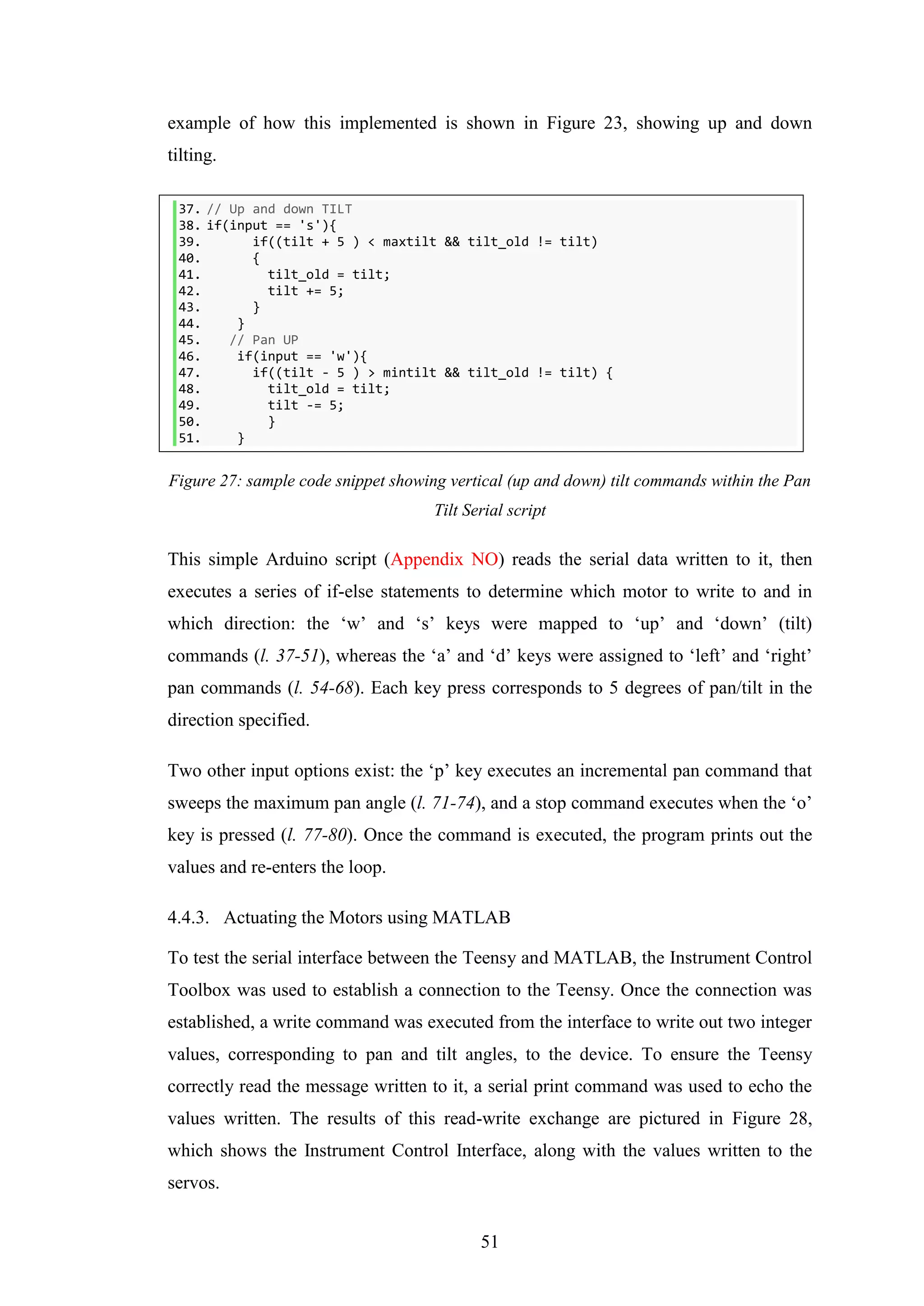

Figure 27: sample code snippet showing vertical (up and down) tilt commands within

the Pan Tilt Serial script...............................................................................................51

Figure 28: the Instrument Control Application Interface in MATLAB, showing the

data read/write operations sent to the Teensy via serial. .............................................52

Figure 29: (left) object centre and bounding box surrounding object; (right)

thresholded version of the image .................................................................................53

Figure 30: the point T (left diagram) corresponds to an equivalent point on an image

plane EFGH (the top of a frustum). The equivalent real-world plane in which T lies

maps out the base of a frustum, E’F’G’H (right). The frustum EFGH-E’F’G’H defines

the projection volume. Reprinted from [38]. ...............................................................55

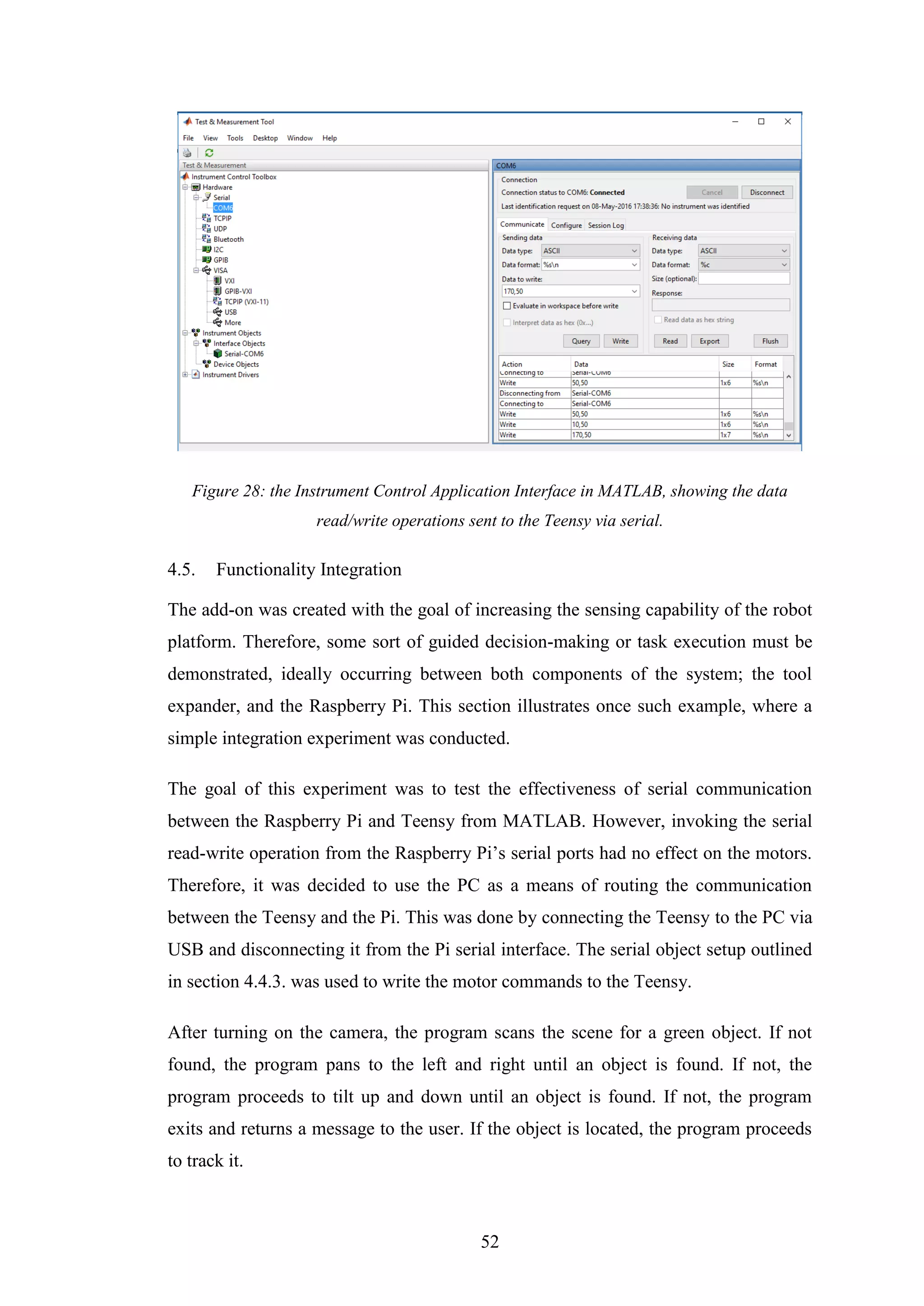

Figure 31: (top left) true-colour and thresholded image with tracked centre; (top right)

variation of x- and y- coordinates of tracked centre; (bottom left) variation of tilt and

pan angles; (bottom right) rate-of-change of pan-tilt angles .......................................57

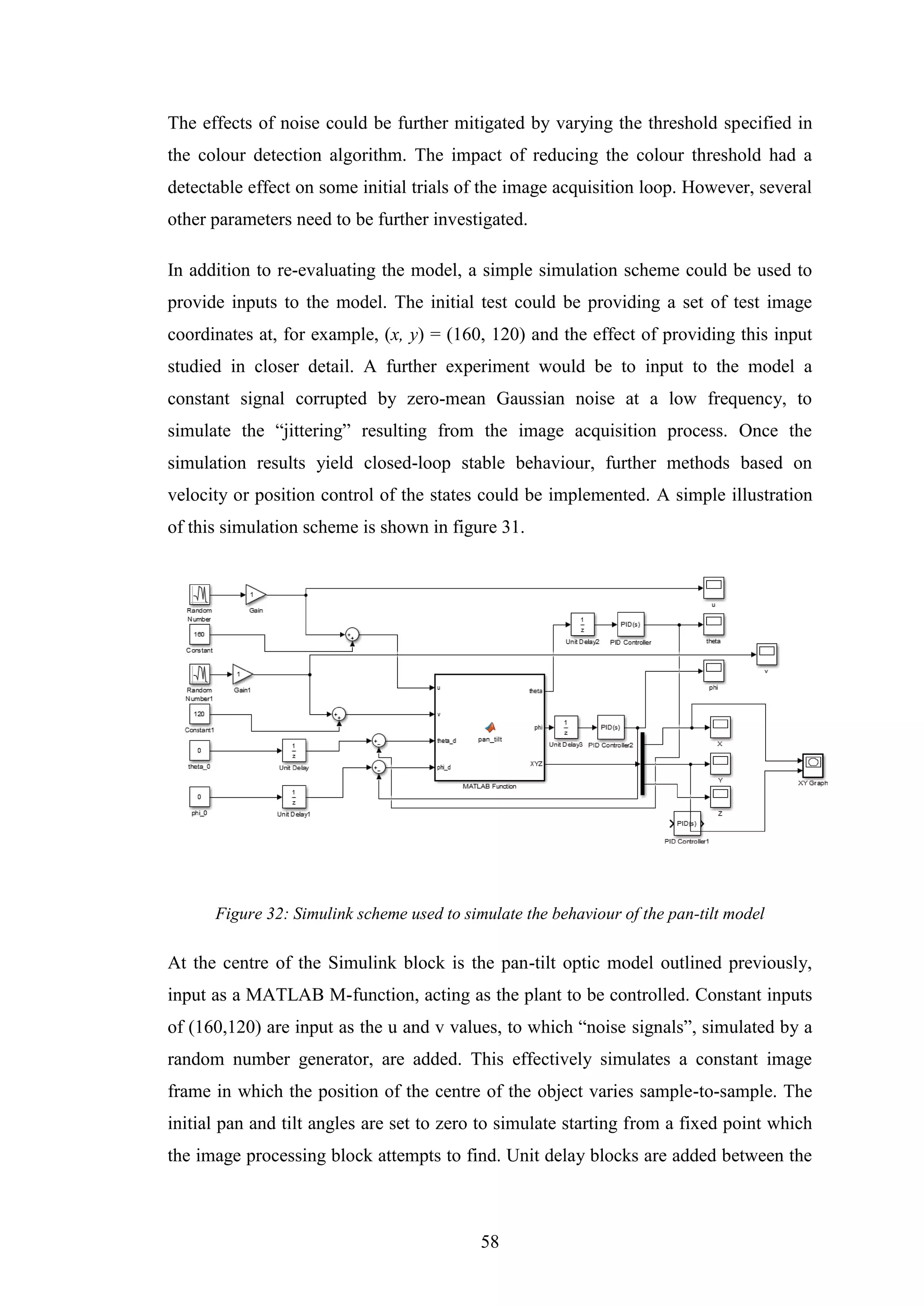

Figure 32: Simulink scheme used to simulate the behaviour of the pan-tilt model.....58

Figure 33: the camera calibration parameters..............................................................61

Figure 34: The camera calibration session in MATLAB. The checkerboard is used to

train the calibrator (top), which generates a pattern-centric view that shows the

position of the camera in the different frames (bottom). .............................................62](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-12-2048.jpg)

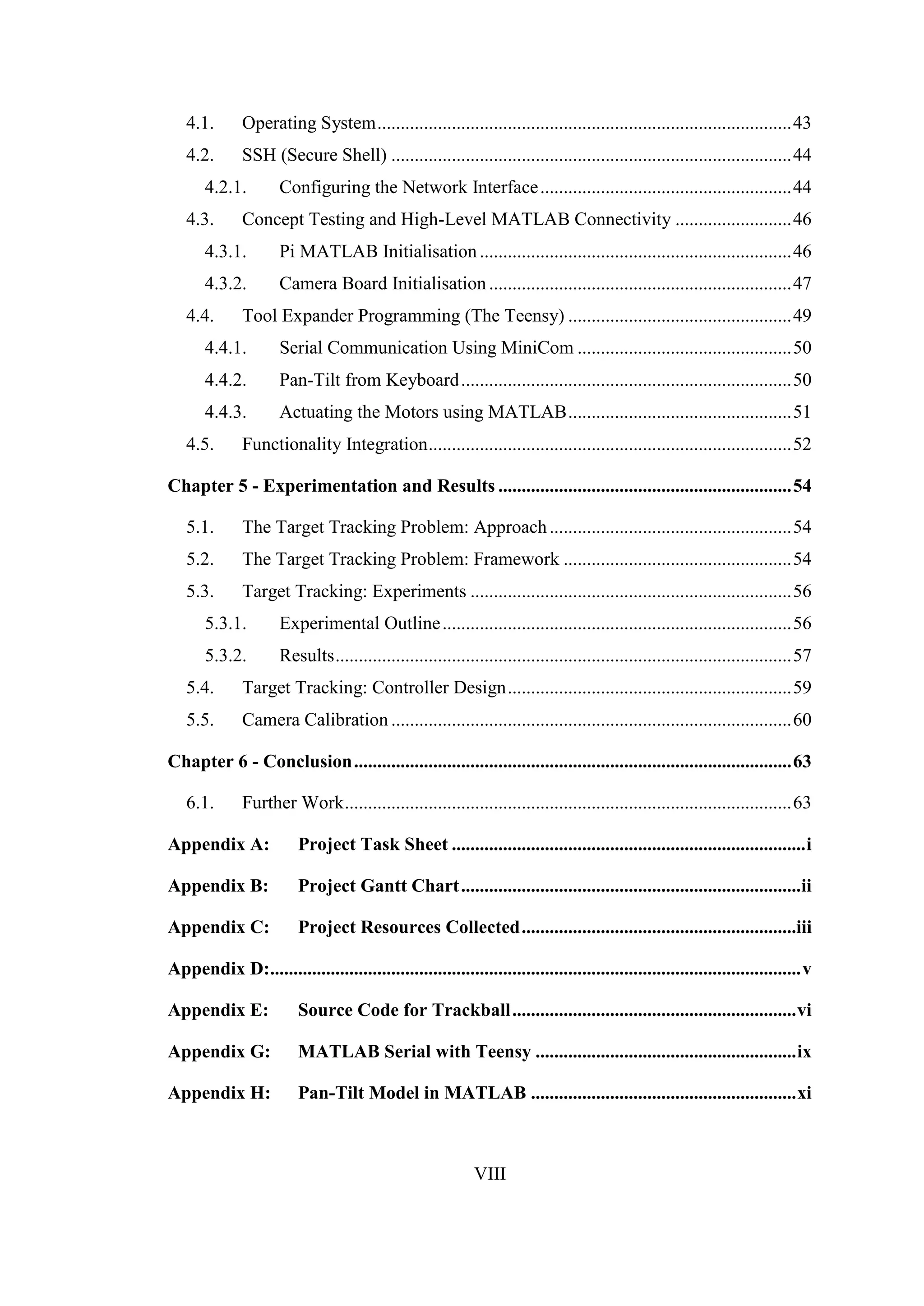

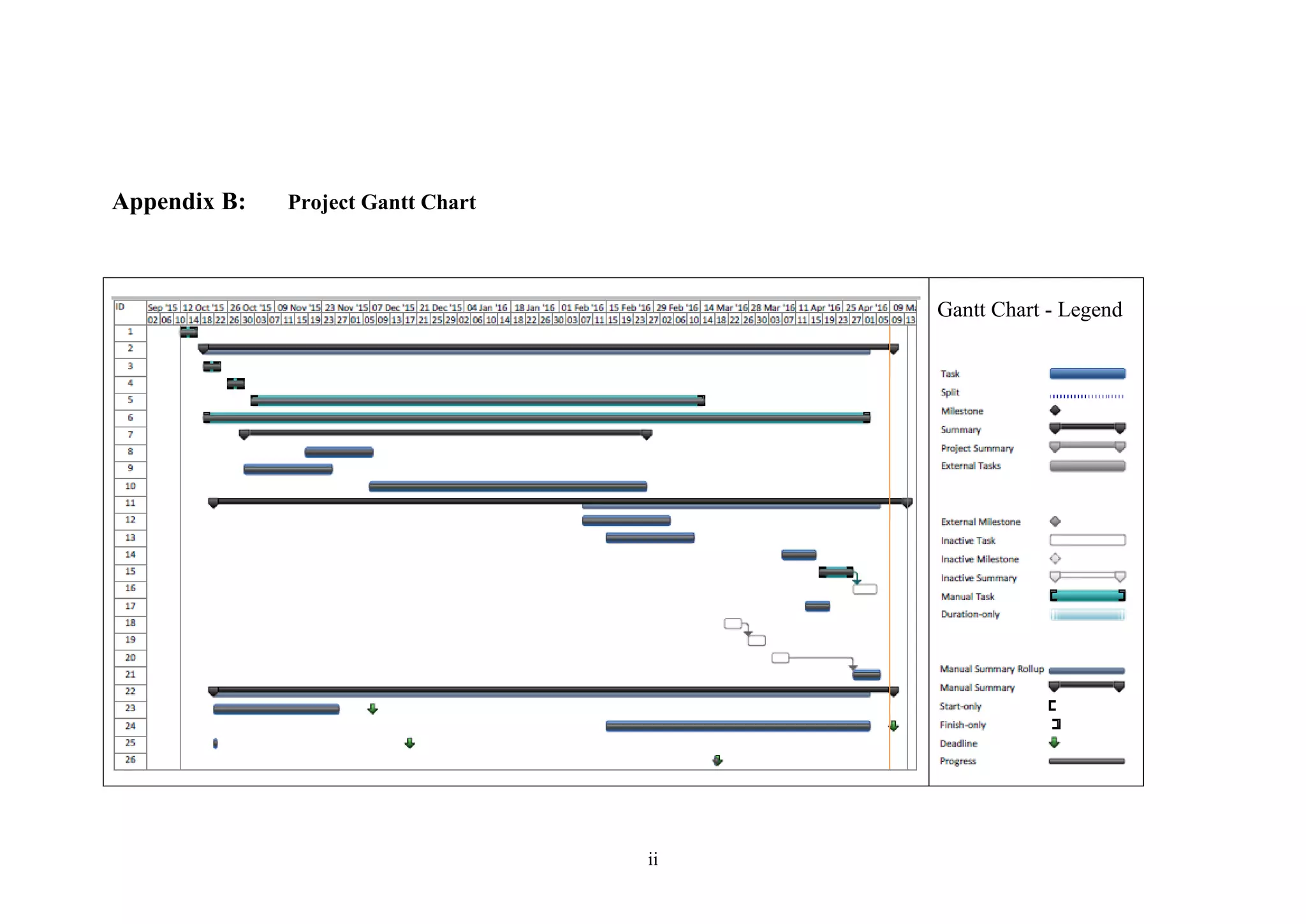

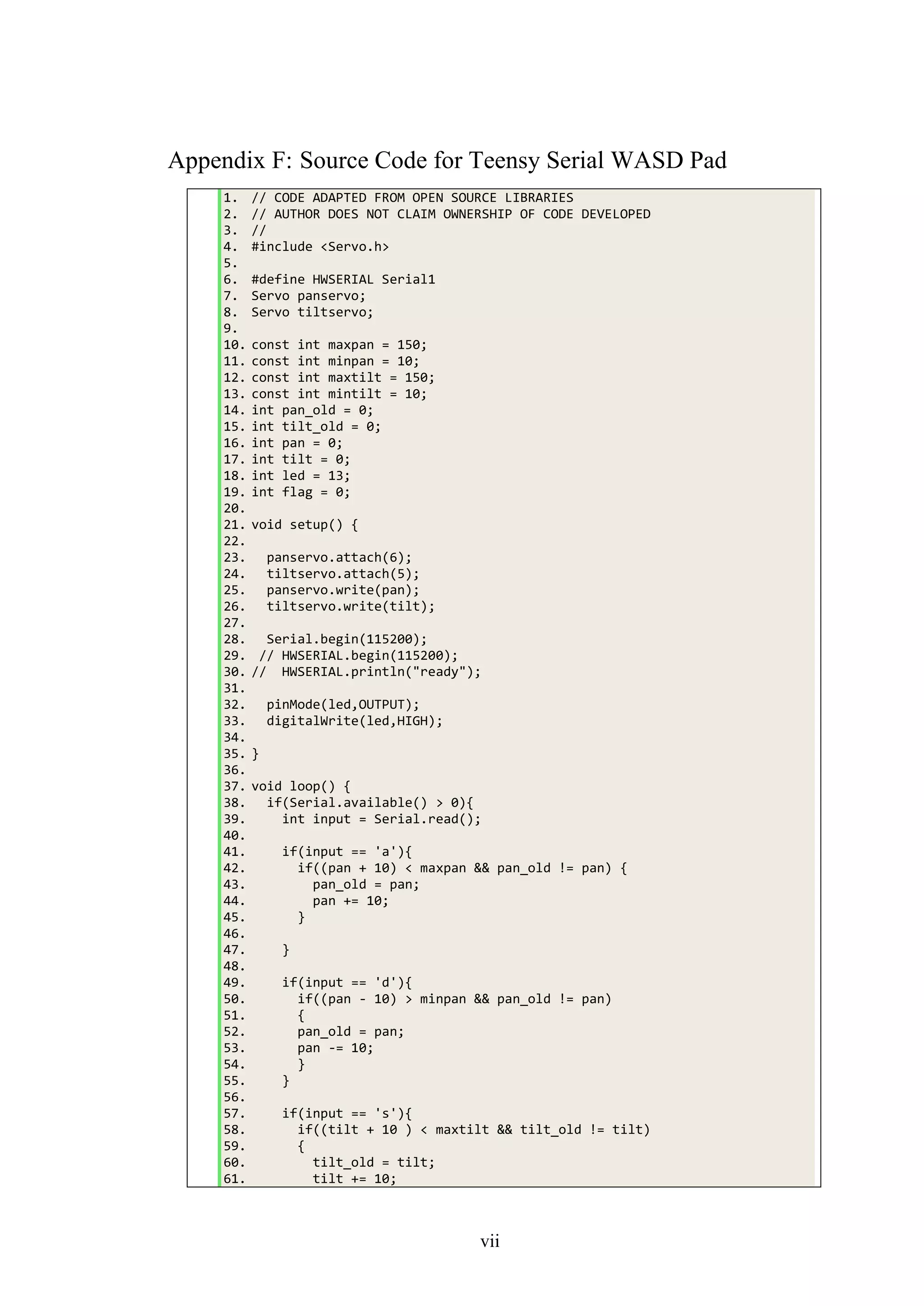

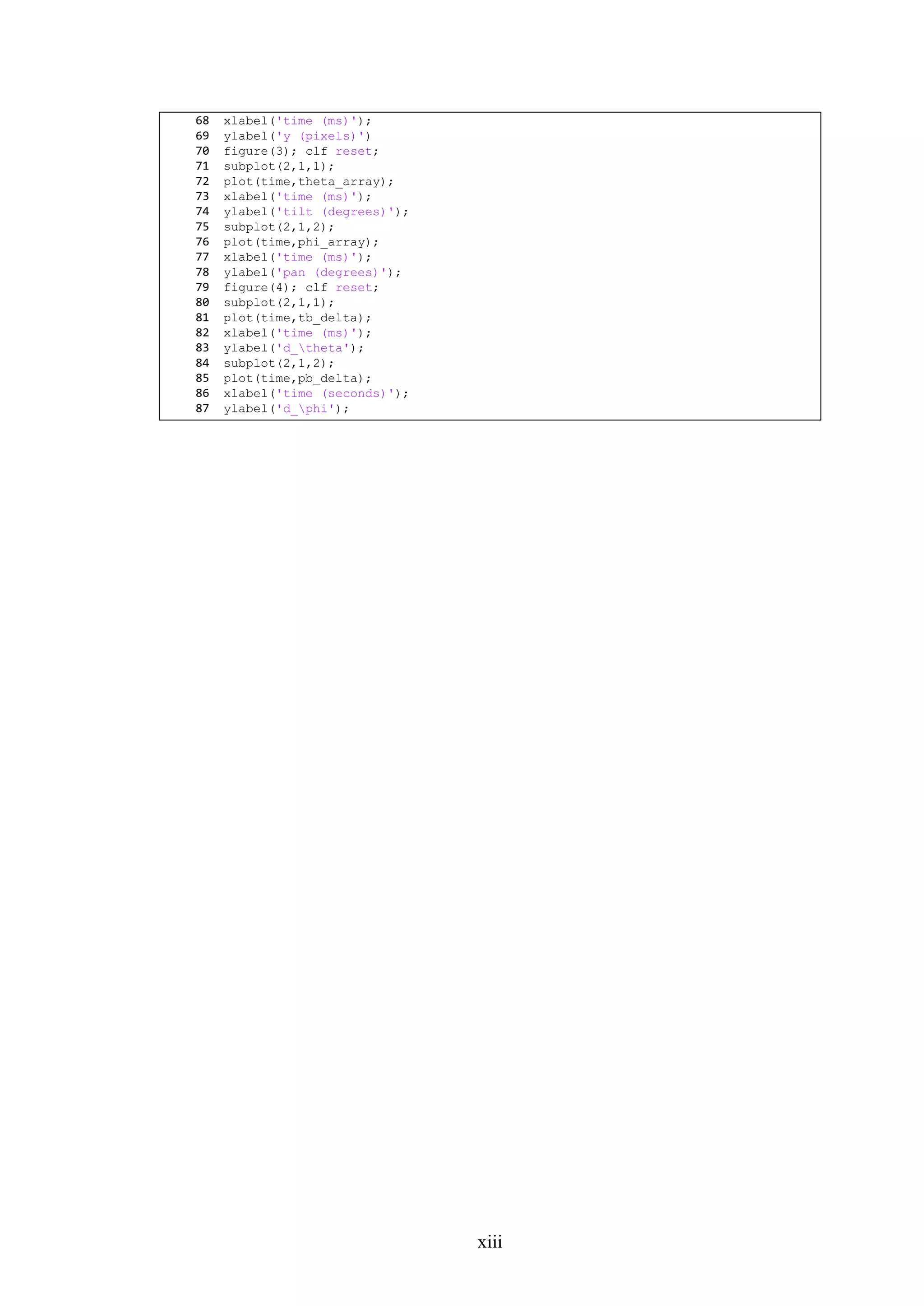

![XIII

LIST OF TABLES

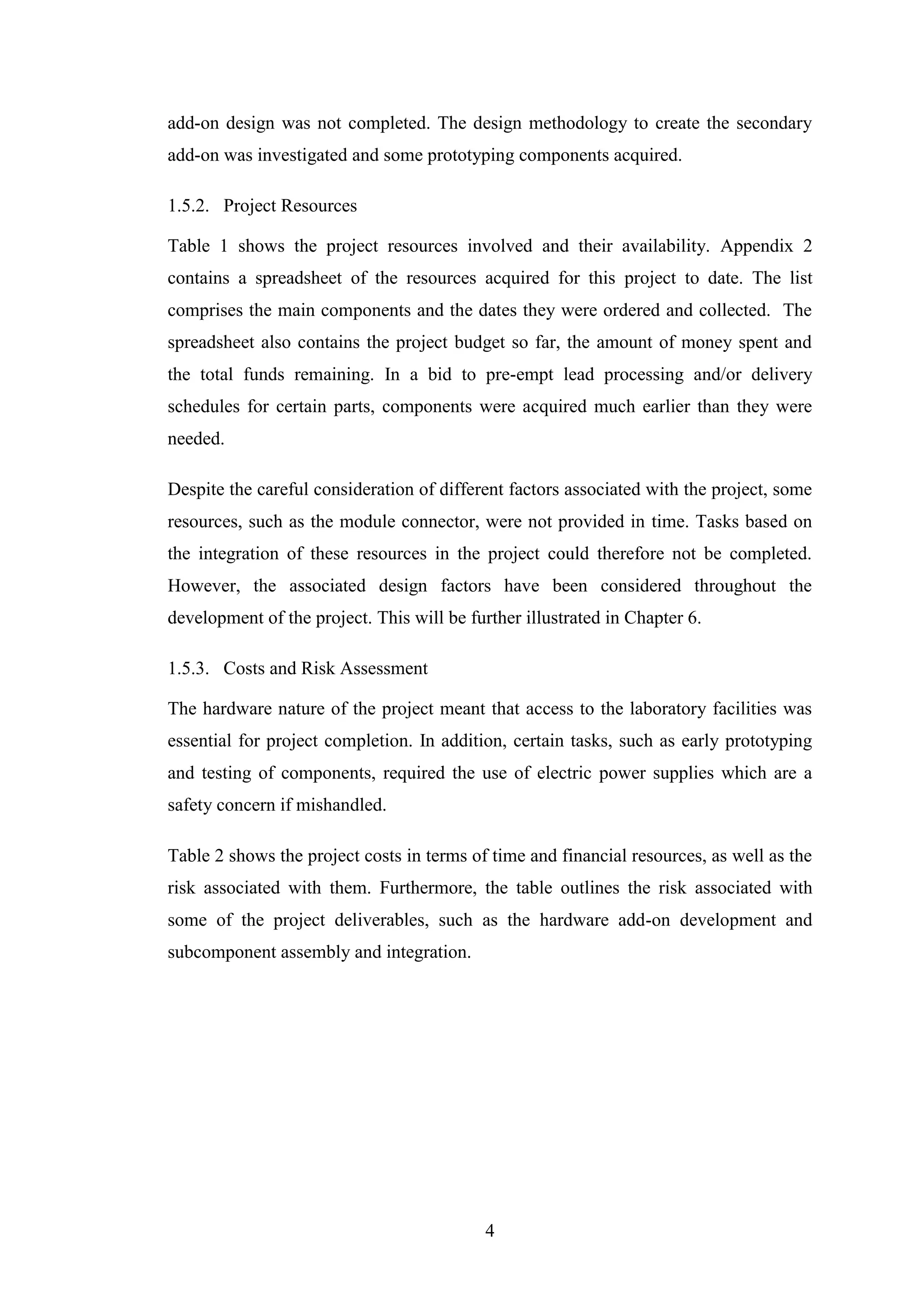

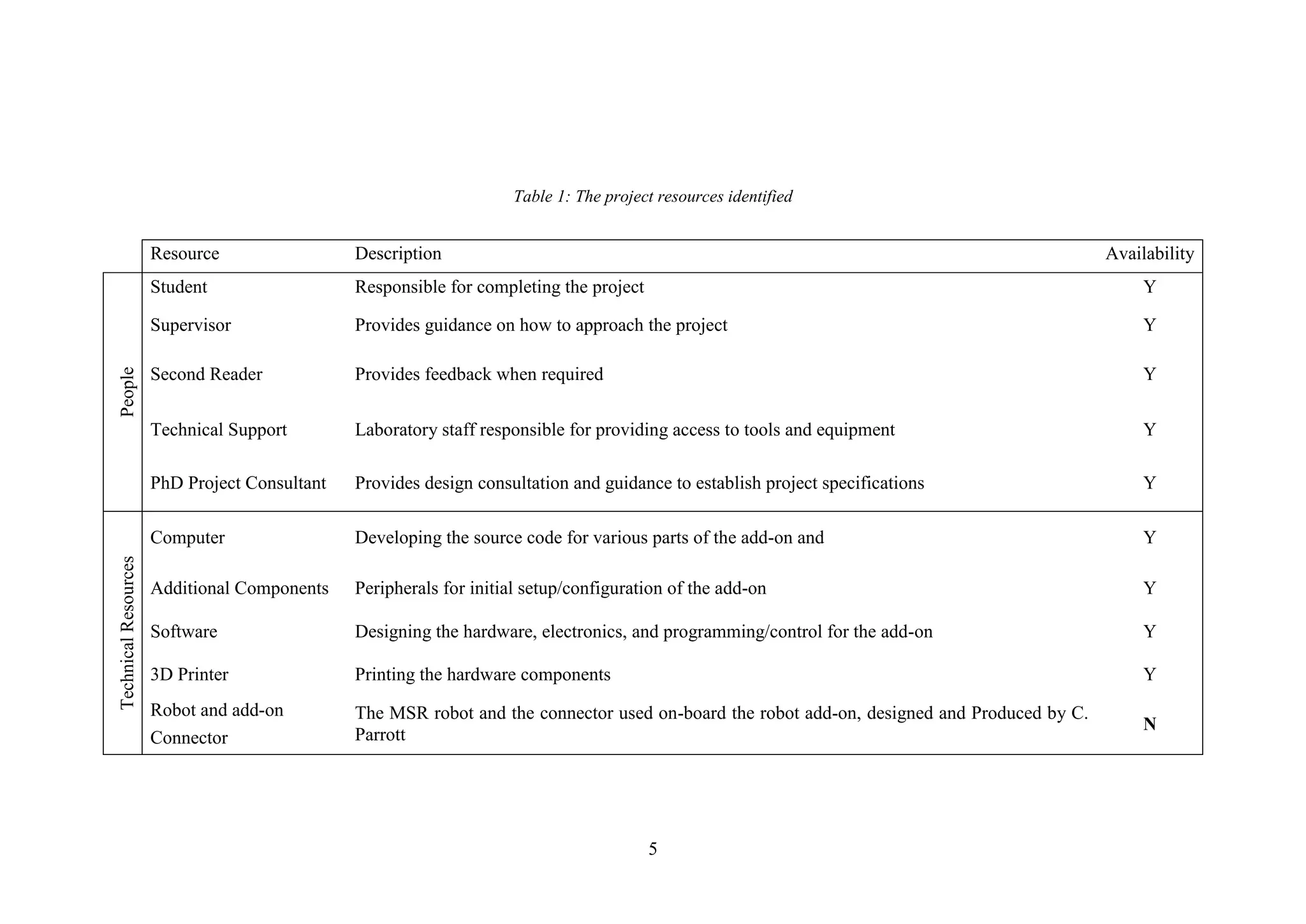

Table 1: The project resources identified ..................................................................................5

Table 2: Cost and risk assessment for the project .....................................................................6

Table 3: ATRON module [3], SMORES [9], AND HiGen [16] connectors and their

properties. ATRON image printed from [1]; SMORES image printed from [17]; HiGen image

printed with permission from C. Parrott..................................................................................14

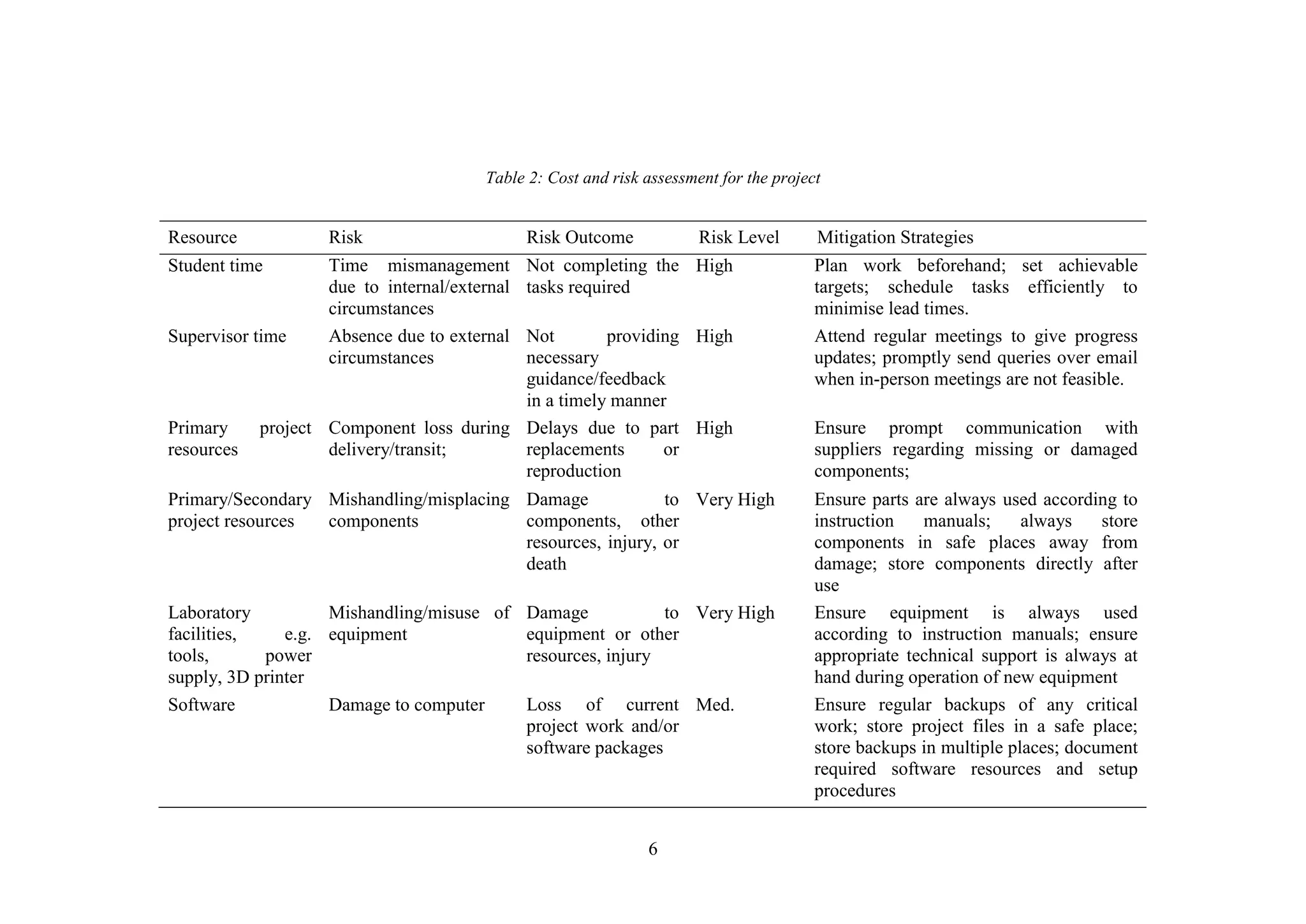

Table 4: Comparing three serial data protocols; SPI, I2

C, and UART ...................................35

Table 5: Tested Current Draws of Multiple Configurations using a 5 V 2 A regulated power

supply.......................................................................................................................................37

Table 6: List of components used within the vision add-on ....................................................42

LIST OF EQUATIONS

Equation 1: the baud rate of the serial protocol for a word size of 12 and a 5 ms sample rate

.................................................................................................................................................36

Equation 2: the pan and tilt angles obtained from the inverse pipeline method described in

[34] ..........................................................................................................................................56

Equation 3: the visual servo (VS) problem as an error minimisation of the target feature w.r.t.

the current camera target. Reprinted from [32]......................................................................59

Equation 4: the interaction matrix of the point x. Reprinted from [32] ..................................59

Equation 5: image coordinates x and y defined in terms of the pixel coordinates (u and v), the

focal length (f), the camera centre (cu and cv), and the pixel ratio α. Reprinted from [32].....60

Equation 6: the velocity of x in terms of the linear and angular components of the target’s

motion ......................................................................................................................................60](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-13-2048.jpg)

![1

Chapter 1 - Introduction

1.1. Background and Motivation

The concept of Modular Self-Reconfigurable Robots (MSR) has been an interest for

many different research groups and institutions. Research in this field has yielded

many unique implementations of multi-robot systems whose units can connect and

disconnect on demand, through actuated connector hubs, either autonomously or by

being joined and separated externally by an operator.

MSR platforms are commonly thought beneficial for modelling and simulating the

behaviours of self-assembling systems at different scales [1], including: enzyme-

substrate and hormone-drug interaction, programmable matter [2], insect swarm

systems [3], and several others. In addition, having a reconfigurable robot platform

could drive forward research in areas such as modular mobile robots [4] or

reconfigurable manufacturing systems (RMS) [5]. MSR systems have immense

potential in applications where cooperative robot behaviour is crucial, such as mobile

search-and-rescue, remote reconnaissance, and space exploration. Authors on this

subject recognize the potential of MSR and self-assembling robot systems, claiming

that once sufficient progress is made in their design as a whole, they will “cease to be

merely biologically inspired artefacts [sic] and become super biological robots” [6].

An MSR platform, however, is usually insufficient on its own - without some way of

showcasing, or indeed improving, its versatility. Often MSR systems are under-

equipped, with limited proprioceptive (internal) sensing and manipulation abilities;

the lack of exteroceptive sensors and manipulation tools limits their environmental

interaction and ultimately their effectiveness as robotic systems. Enter hardware

extensions (add-ons); they enhance the system capabilities by substituting their end-

effectors. For hardware extensions to work effectively with their intended platform,

they must comply with specific design criteria, dictated by the platform in question.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-16-2048.jpg)

![2

1.2. Problem Definition

The limited ability of MSR systems to perceive and affect their environment stands in

the way of practical realisations of such systems. Application-Oriented Hardware [1]

is therefore used to tackle this problem, by augmenting the robots’ sensory and/or

functional capabilities. To this end, a recent development at the University of

Sheffield, the HiGen Module [2], attempts to produce an MSR system which is

readily expandable through hardware add-ons. This project aims to further expand on

the applicability of hardware add-ons, through designing a complete multifunctional

add-on that could be readily integrated with the HiGen platform.

1.3. Aim of the Project

The aim of this project is to study, design, and build hardware extensions, or add-ons,

for an MSR platform currently under development at the University of Sheffield.

1.4. Objectives of the Project

The objectives of this project are:

1.4.1. Primary Objectives

Research the area of modular self-reconfiguring robots, and review the most

relevant implementations of MSR systems to date, including systems capable

of independent locomotion, heterogeneous systems, and systems with

hardware extensions (add-ons).

Research applications of MSR systems, including general and industrial

applications.

Design and program a hardware extension (add-on) to increase the sensing

ability of the MSR system under development.

Build, program, and test the hardware add-on.

1.4.2. Stretch Goals (Advanced Objectives)

Some advanced objectives have been outlined at the start of the project. However, due

to time constraints they were partially side-tracked to focus on the initial objectives.

Modify an existing hardware add-on to use in conjunction with the system.

Conduct experiments to ensure the efficacy of the hardware add-ons.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-17-2048.jpg)

![9

Chapter 2 - Literature Review

The concept of Modular Self-Reconfiguring Robots (MSR) has been an interest for

numerous different research groups and institutions. Research in this field has yielded

many unique implementations of multi-robot systems whose units can connect and

disconnect on demand, through actuated connector hubs, either autonomously or by

being joined and separated externally by an operator. However, an equivalent amount

of research has emerged attempting to assess the potential of MSR platforms in terms

of real-world applications.

This chapter highlights research endeavours in modular self-reconfiguring robot

systems, from their initial conception and a brief general history, to early

developments including a host of systems that have been designed for different

problems and use cases. It also introduces MSR systems with hardware add-ons and

Reconfigurable Manufacturing Systems (RMS). Next, the chapter illustrates some of

the implications of MSR system design as well as the challenges facing such systems.

Finally, the chapter introduces the HiGen connector and MSR system, for which the

hardware add-ons have been designed.

2.1. Modular Self-Reconfigurable Robots: A Brief Overview

In the 1940’s Alan Turing introduced the concept of a universal computation device

[1], one that could perform any task required through reprogramming. By the 1970’s

personal computers had gained significant traction within the consumer goods market,

ushering in a new age of innovation through technology, consequently fulfilling

Turing’s vision. Successive advancements in computer technology have driven

numerous innovations in mobile robotics, and in turn, small-scale mobile robots.

1988 marked the first theoretical implementation of a dynamically reconfigurable

modular robot, one that could be constructed from basic ‘cells’ or ‘modules’ and

reconfigured autonomously as per the desired use case [3]. Following on from these

theories, many research groups have successfully built and simulated robotic systems

comprising basic modules capable of different types of reconfiguration.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-24-2048.jpg)

![10

As of 2014 there have been at least 40 different implementations -and counting- of

MSR systems, with each system aiming to address a specific set of design challenges.

These challenges encompass novel connector designs, unique control methodologies,

or improved communication, to name a few. It is worth noting that some of these are

iterations of previous systems.

2.2. Modular Self-Reconfigurable Robot Systems: Taxonomy and Attributes

MSR platforms comprise basic building blocks that can reconfigure into different

shapes to perform the desired task. A single module contains all the working internals

of a robot: sensing, actuation, battery, and processing power. Though virtually useless

as individual robots, MSR platforms draw their immense potential from scalability;

ten, even hundreds, of modules can combine together in any configuration forming

rigid, complex structures and functional limbs. An example of a MSR platform, the

ATRON self-reconfigurable robot [4], is shown in Figure 1, with individual modules

combined into different configurations.

MSR systems are classified into three main archetypes: pack robots (consisting of

dozens of robots within the same system); herd robots (with several hundred modules

per system); and swarm robots, whose numbers are typically many thousands of units.

The significance of each module within the system decreases proportionally with the

size of the MSR population; pack robots are the most dependent on the actions of

each individual, whereas in large swarms of robots no particular attention is paid to

single modules, much like natural swarm systems.

Another method of classifying MSR platforms is based on their reconfiguration

abilities. The robots are said to be reconfigurable if they can be

connected/disconnected and combined into different configurations; dynamically

reconfigurable, if they can disconnect /connect while modules are active (hot-

swapping); and self-reconfigurable, if they can be connected/disconnected

autonomously, without external aid.

This section introduces the general attributes of MSR systems, including their

morphology, locomotion classes, control, connector design, and communication

methods, with references to existing implementations.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-25-2048.jpg)

![11

Figure 1: the ATRON self-reconfigurable robot combined into a snake configuration (left), a

vehicle-like configuration (right), and an intermediate configuration (back). Printed from [3]

2.2.1. Morphology: Lattice, Chain, and Hybrid

MSR systems are commonly characterized using their morphology [1], which is

primarily concerned with how the robots are assembled into structures. Chain-systems

are where the individual robots combine together end to end in chain-like shapes,

trees, and loops in some cases. Lattice-systems, such as Fracta [5] and the

Metamorphic Robot [6], are examples of predominantly planar (2D) architectures

where each robot unit is connected to two or more units, consequently requiring

multiple connection points. Robots in a lattice only connect in discrete points in the

configuration, akin to how atoms combine to form structural lattices. Hybrid

architectures, such as the ATRON [4], also exist where combinations of chain clusters

and lattice structures could be formed using the same basic building blocks [7]. Such

systems allow multiple legs to assemble, providing greater locomotion versatility,

whereas lattice arrangements allow rigid support structures to form, improving the

stability of the whole system, in addition to facilitating self-reconfiguration tasks. For

these reasons, hybrid architectures tend to prevail throughout MSR designs.

Determining the intended morphology of the system is a consideration that takes form

at the module and system level alike. As shown in figure 2, Stoy et al. have

demonstrated that the MSR morphology largely dictates other aspects of the design

[4]. The fact that most morphologies tend to be hybrid slightly simplifies this from a

mechatronic design point of view, but might cause a plethora of challenges for control

design. This will be discussed later in this section.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-26-2048.jpg)

![12

Figure 2 showing the components involved in robot design and their interaction. Adapted

from [8]

2.2.2. Locomotion Modes

A crucial design element for MSR platforms, and perhaps one of their most

advantageous traits, is the various locomotion modes they inherently support through

reconfiguration [3] [8]. Some MSR systems have been created to have independently

mobile modules, such as M3

Express [9], SMORES [10], M-TRAN [11] and PolyBot

[12] [13], whereas most are only capable of propulsion in clusters [4]. Many MSR

systems can form into different configurations capable of varying locomotion modes.

For example, ATRON [4] can form snake-like or “wheeled” robots, and M-TRAN

can form into multi-legged configurations. Kutzer et al. proposed a MSR design with

a hybrid morphology, whose modules were capable of self-propulsion on disc-shaped

connectors that doubled as wheels [9]. Those could be used to propel individual

modules or a large multi-robot cluster.

Another interesting prospect for MSR locomotion lies in the individual flexibility and

self-locomotion of the modules combined with the structural support and rigidity of

the MSR as a whole. Within a large cluster or multi-robot, robots could move from

the back of the configuration to the front, or holes move to the back of the robot,

creating what is known as cluster flow [14], moving the robot in a specific direction.

Several examples of cluster flow exist in MSR platforms, both physical and

simulated, some of which have been reviewed in [15]. Similar behaviour is exhibited

in real-life insect swarm systems such as ant colonies, whereby ants form into large

structures that self-propel across a terrain or conform around an obstacle to navigate

their path.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-27-2048.jpg)

![13

The locomotion versatility of MSR platforms proves invaluable in the presence of

unstructured environments, making them ideal candidates for space exploration,

reconnaissance, or remote search and rescue tasks. However, until certain design

challenges are mostly overcome, these benefits remain largely hypothetical, save for

the few example MSR systems that have demonstrated animal-like locomotion.

Cluster flow and task-based growth are examples of challenges that might be

overcome once single modules are efficient enough.

2.2.3. Control

Self-reconfiguration control in MSR systems poses a significant multi-layer

challenge. At the module level, control of on-board mechatronics to arrive at the

desired configurations requires a complete understanding of the system kinematics,

posing a hardware challenge of itself. The obvious solution to this problem is to

restrict the DOF count on each module, rendering them simpler but less versatile.

Even controlling chains of simple 2DOF modules becomes challenging from a

software perspective. Adding an extra module increases the difficulty of docking two

units at different points together, as arm, and therefore chain, poses grow less singular

and more error-prone with each joint added [1], unless direction constraints are

employed. This increase in complexity degrades the computational efficiency of the

controller in question. For embedded controllers, this becomes even more

challenging, as individual robots are, by design, often limited in terms of memory and

processing power.

Globally, it is not feasible to instruct all modules to converge to a certain

configuration; however, it is possible to guide them to incrementally approach one

another, thereby allowing them to reconfigure [1]. Some researchers proposed control

paradigms by which only certain modules performed the required control action; the

surrounding modules then use their internal models to “follow suit”, effectively

enabling the modules to form the desired configuration or execute cluster flow. This

leader-follower approach has been adopted by Stoy and Nagpal [16].

Control of individual modules is almost only necessary in cases where precise self-

reconfiguration is required, for example if the end-goal is to reconfigure into a

specific shape, such as an arm or leg for locomotion. However, for some tasks such as](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-28-2048.jpg)

![14

cluster flow locomotion and task-driven growth, it might not be entirely necessary, or

indeed feasible, to control individual robot modules.

2.2.4. Connector Design

A fundamental hardware challenge for MSR platforms lies in the design of robust

connectors capable of lifting multiple units in series, with minimal actuation time. Of

great importance, as well, are the modules’ having a simple alignment mechanism and

control implementation. Genderless connectors excel in comparison to the other

methods. Connectors can be mechanical, electromagnetic, or magneto-mechanical,

though other methods have also been used.

In [2] Parrott et al. compared three classes of connector designs: gendered, where

male connectors latch onto chassis parts by means of hooks or pins; bi-gendered

(hermaphrodite), where pins/hooks latch into connector grooves; and genderless,

where two hooks latch together. Table 1 presents some different connectors that have

been implemented, comparing their properties.

Table 3: ATRON module [4], SMORES [10], AND HiGen [2] connectors and their

properties. ATRON image printed from [1]; SMORES image printed from [17]; HiGen image

printed with permission from C. Parrott.

Robot

System ATRON SMORES HiGen

Connection

Mechanism

Mechanical Magneto-Mechanical Mechanical

Connector

Gender

Gendered (male

hooks attach to

female slots)

Bi-gendered (modules

have in-built features

of both genders)

Genderless

(connecting faces

have identical

interlocking hooks)

Connector

Face

(Pictured)](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-29-2048.jpg)

![15

2.2.5. Sensing

Numerous experiments conducted on MSR platforms aim to understand how capable

the modules are of cooperating under various circumstances. The limited capabilities

of MSR platforms in the way of exteroceptive sensing consequently limits their task

execution abilities. Most MSR systems are restricted to using a few types of

exteroceptive sensors (that measure external environmental variables such as

temperature, humidity, light), save for SWARM-bot [18] which employed various

exteroceptive and proprioceptive sensors. Consequently, if the robots were to affect

their external environment, some way of enhancing their awareness of their

environment is crucial for cooperation, particularly in unstructured settings. Several

researchers have devised non-vision solutions to tackle the problem of self-

reconfiguration, one of the most challenging aspects of MSR implementation.

Payne et al. [19] propose localization based on elliptical approximations to estimate

probable robot locations. While their algorithm is fast and light, producing robust

estimates of robot locations from one Infrared sensor per robot in a few samples, it is

sensitive to varying light intensities and is therefore less effective in environments

with varying lighting. Furthermore, the availability of cheap low-power

microprocessor and memory modules renders computational requirements trivial, so

embedded robust sensing can easily be exploited.

2.2.5.1. Vision: Motivation

Vision presents itself as a suitable candidate due to its simple implementation and

relatively well-understood requirements. A multitude of different camera technologies

that can generate medium-resolution, high-speed video or MJPEG (a sequence of

JPEG images “stitched” together to form low-framerate video) do exist, rendering the

task more manageable. Simple implementations of camera-based navigation use low-

level image processing to guide the robots’ decision-making with respect to the

environment, or based on the task at hand.

2.2.5.2. Vision: Implementation

In experiments by Yim et al. [20] [21], the CKBot system used smart camera

attachments on three module clusters (each cluster comprised four modules connected

together) to form a bipedal robot. Each camera comprised a VGA imager, an Analog](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-30-2048.jpg)

![16

Devices Digital Signal Processor, a 3-axis accelerometer, and a wide-angle signalling

LED. The camera communicated with the robots over a CAN bus, and the robots

could be fitted with Bluetooth transceivers for wireless cluster intercommunication.

The module also featured an independent power supply, increasing the duration of its

usability. It was screwed to the robot cluster, as opposed to using the magnetic

connectors on-board the modules. To test the effectiveness of this vision and

signalling platform, the robot was forcefully separated (or exploded) by a kick from

the experimenter. Using visual servoing, the clusters autonomously scanned the scene,

detected LED signals from the other robots and moved towards them. The clusters

successfully regrouped, realigned and reconnected into their previous configuration.

Vision has also been implemented within the CONRO system [22]. The researchers

have devised a simple CMOS camera sensor that could be attached to some of the

robot modules. The module was capable of capturing 8-bit monochrome images at 30

fps. While the modules did not have the computational capabilities to capture or

process the image at the time, it was a step forward in empowering simple MSR

robots with camera sensors.

Simple 2D-vision is not the end goal, however. Some experts suggest using multiple

MSR clusters to create 3D maps of their surroundings using inexpensive cameras and

IR transceivers, as opposed to expensive sonar or LiDAR (Light Detection and

Ranging) sensors. This would be practical in applications where creating a 3D map of

an inaccessible environment is required, such as in a collapsed building, inside a tank

or cave. Powerful and inexpensive computers would allow sophisticated image

processing software to be embedded, and enable the robot to do more with the data

collected.

2.2.6. Communication

Many MSR platforms employ multiple communication modes between robots to

allow them to cooperate and navigate unforeseen obstacles. Robust communication

enables efficient use of sensory data. In addition to redundancy, which pre-empts

potential failures and provides fall-back routes, the communication methods

employed might be desired for specific tasks. For example, aside from a Controller

Area Network (CAN) bus using the Robotic Bus Protocol for data transfer between

robot modules, the CKBot modules [20] supported optional Bluetooth inter-cluster](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-31-2048.jpg)

![17

communication. A similar principle has been adopted with the HiGen module. This

will be discussed later in the chapter.

The communication modes used are typically chosen based on factors such as desired

range, latency, implementation simplicity, and system control requirements. For task-

dependent communication, attention must be paid to how these decisions would

influence the robot’s ability to conduct its task in the real world. For example, a

particular mode of communication might have a sufficient range in open spaces, but

be susceptible to attenuation in enclosed areas or in the presence of large obstacles.

Selecting a powerful and versatile communication platform is therefore a crucial step

in MSR design, to ensure the robot can perform its task without interruption.

2.3. Heterogeneous MSR Systems

The use of swappable ‘quick change’ tools on CNC milling machines could be

loosely regarded as the first practical implementation of a reconfigurable robot system

with an add-on. In 1988, the first implementation of a self-assembling robot, formed

of heterogeneous modules, the CEBOT (short for cellular robot), was achieved by

Toshio Fukuda [3]. He devised a system comprising three types of units; Type 1

locomotion modules (joints or wheels); Type 2 structural (branching or power)

modules; and Type 3 functional (tools or grippers) modules. Later robots build on this

concept, but attempt to combine the structural and locomotion aspects, effectively

producing modules with actuated DOFs, power sharing and multiple connector hubs

all in one. Functional modules, however, remain mostly separate and are designed to

be changeable depending on the task required.

2.3.1. MSR Systems with Hardware Attachments (Add-ons)

Stoy et al. describe the implementation of “application-oriented hardware”, or

hardware add-ons, as one of the crucial steps towards realising practical MSR

platforms [1]. It is well recognised that practical implementations that use hardware

add-ons make the robot platform less homogeneous in nature. However, as long as the

majority of the robot is composed of identical modules, barring the add-ons, the MSR

would still qualify as a homogeneous system.

The AMOEBA-I platform [23] is an example of a robot system which, while shares

some common features with MSR systems, cannot be classified as such. Instead this](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-32-2048.jpg)

![18

system sacrificed the prospect of homogeneous structural self-reconfiguration for

practicality. The robot’s chassis could be rearranged into different shapes, and it made

extensive use of hardware attachments to vary its suitability for certain tasks such as

search and rescue or military reconnaissance. The robot could employ different

configurations of tires or treads to increase its locomotion versatility, and had

functional add-ons which could be attached to various parts of it.

In a similar vein to Fukuda’s early visions, Akin et al. propose MORPHbots [24], an

MSR with anthropomorphic robotic manipulator arm linkages with interchangeable

end-effectors, to assess the space exploration capabilities of MSR systems. The 6-

DOF arm with a genderless connector had a spherical workspace. Impressively, at just

10 kg, it was capable of tasks an astronaut in a pressure suit would normally execute.

MORPHbots featured three component types: modules, providing manipulation

capabilities (such as pitch/yaw and prismatic actuators); nodes, serving as branching

points and can also provide additional networking hubs and computation capabilities;

and packs, providing additional services (battery packs, power generation, sensors,

tool carriers, or communications devices). These components (modules, nodes, and

packs) then combine together into entities, grouped together into a system.

Using similar principles, Researchers in [25] developed Thor: A heterogeneous MSR

system with eight different module types: motors; cubic nodes (with six hub

connectors); rotation 165 (capable of rotating ±165°); angle 90; wheel; gripper;

battery; and wireless. These are some implementations resembling what Yim et al.

call a “box of stuff” [26], which could be likened to a robotic Swiss army knife.

While the idea of dedicated functional units that provide only the necessary

functionality is attractive for well-understood applications, it may prove unnecessarily

restrictive. It could result in a more complex overall implementation as systems would

require multiple entities, each of which responsible for one part of a multi-task

mission. A system would be rendered useless against a particular task without

precisely the right attachment(s) equipped, so it would not be suitable for stochastic

environments. Conversely, designing the components as multi-purpose tools would

increase versatility at the cost of implementation complexity.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-33-2048.jpg)

![19

2.3.2. Reconfigurable Manufacturing Systems (RMS)

Drawing on inspiration from MSR systems such as PolyBot [12] [13], and

particularly the work of Fukuda on CEBOT [3], Chen proposed a heterogeneous

system of workcells [27] that could reconfigure according to the demands of the

production line, as opposed to using traditional single-purpose manipulators or

manufacturing lines. The workcells comprised passive joint modules which also

contained sensors for accurate positioning and internal measurements, and various

active actuation modules, such as prismatic and rotational joints. His intended

customers were high-mix and low-volume manufacturers who required their

production facilities to quickly adapt to the market.

Chen successfully demonstrated the versatility and reconfiguration capabilities of his

RMS by constructing and showcasing a light machining prototype system at the

International Industrial Automation Exhibition in 1999. Provided they were capable

of kinematic efficiency similar to traditional industrial robots, RMS’s would be

beneficial to medium scale manufacturers – so long as their large initial investment

cost could be justified [28].

2.4. Design Challenges of MSR Platforms

According to most experts in this field, the problem of optimizing MSR design,

including which features to incorporate, is dependent on the intended application of

the system [1]. It is largely accepted that a “killer application” [26] that would help

specify strict design goals for MSR platforms has not yet been discovered, making the

problem much more difficult to characterize. Few systems have therefore been created

with the goal of optimal design in mind. SuperBot [7], a University of Southern

California platform created in 2006, was an MSR whose design goals were focused

towards optimality. This prominent example, partially funded by NASA and the US

Army Research Office, featured rigid, robust modules, each of which had 3 degrees of

freedom (DOF), an array of exteroceptive sensors, and fault-tolerant adaptive control.

While a lot of practical results have painted MSR platforms in a ubiquitous, all-

purpose light, it is important to acknowledge their shortcomings in certain areas.

Those are most notably computational weaknesses, design challenges, exteroceptive

deficiency, and control-related challenges, such as autonomous self-reconfiguration.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-34-2048.jpg)

![20

This section discusses some of those challenges and presents ways to deal with them

within MSR design. Once these have been fully addressed by the researchers

involved, implementations of MSR systems will start to verge on the ideal picture

most commonly depicted in science fiction.

2.4.1. Computational Limitations

Firstly, most such platforms are severely restricted in terms of their computational

real-estate. Owing to the specific niche application areas, MSR platforms and their

accompanying extensions do not typically feature computationally powerful

components. At most, some systems have been able to demonstrate some degree of

high-level data manipulation in the form of image processing, an arguably taxing feat

using the proposed implementations. In the case of the CONRO robot, for example,

the researchers were not capable of capturing, let alone storing, an image directly on

the robot [22].

Memory bottlenecks and fragmentation are some other likely outcomes in systems

whose programming is ad hoc. Memory mismanagement could cause frequent crashes

which are to be avoided at all costs if precise self-reconfiguration is the ultimate goal.

Furthermore, for the tasks of surveying or data collection, the robots would have very

little, if any, available storage to retain any data recorded. In a practical scenario, it

might not be feasible to live-stream data, especially under strict limitations of

available power; periodic data collection could therefore be the only viable option,

and full access to the data could only be attained on retrieval of the robot.

2.4.2. Power Sharing

Power sharing is one of the potential benefits of MSR platforms, yet it remains an

elusive goal to many researchers in the field. To this date, power sharing across an

MSR system is a huge obstacle to robust and efficient self-reconfiguration. Several

implementations have used external connecting wires to emulate power sharing,

though few have been successful at embedding power-sharing functionalities within

the MSR’s connectors.

Challenges lie not only within the design of the electrical and electronic infrastructure

of the MSR itself, but also within optimising the design of the connector mechanisms

to allow for reduced energy expenditure while maintaining sufficient actuation power.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-35-2048.jpg)

![21

This means that connection mechanisms must be designed with maximum connection

speed as a main goal, to reduce the energy cost of reconfiguration.

Another hurdle is the availability of battery technologies capable of sustaining

prolonged operation as well as enduring repeated discharge and recharge cycles.

2.5. The HiGen Modular Robot

This section introduces the HiGen module [29], along with the connector design

which serves as the connection point between the robot and the add-on.

2.5.1. The HiGen Module and Connector

The add-on is being developed to be used in conjunction with the HiGen module, a

140 mm × 140 mm spherical-shaped robot, featuring four HiGen connectors. As

discussed earlier, the genderless nature of this mechanism allows single-sided

connect/disconnect, and outperforms other connector implementations in terms of

actuation speed and efficiency [2]. Figure 3 shows the connector (left) and a single

robot module (right) equipped with four connectors. To ensure the add-on would be

compatible with HiGen module, the hardware choices and implementation method

were agreed with Christopher Parrott, the PhD candidate responsible for the HiGen

module design.

Figure 3(a) and (b): standalone HiGen connector module (left) [20] and HiGen modules on

the self-reconfigurable modular robot (right) [28]. Printed with permission from C. Parrott,

2014.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-36-2048.jpg)

![24

Chapter 3 - Hardware Design

The hardware design encompasses two main areas; the chassis design (the enclosure

for all the electronics components and the pan-tilt mechanism), and the electronics

design (the Raspberry Pi, the tool expander board, and the connector controller).

Firstly, this chapter introduces the design requirements for the hardware extension,

including functionality, performance, compatibility, and usability. In addition to

presenting early concept prototypes, this chapter outlines the process of designing the

custom-built components, presents arguments for certain design choices including

component choices, and presents the final hardware design and all of its components.

3.1. Design Requirements

From the literature review conducted in the previous chapter, it was decided to use

vision as the primary method of sensing based on which the add-on would be

constructed. The add-on would be used in a similar fashion to those designed by Yim

[20] and Castano [22].

Before the design process could commence, it was important to fully define the

problem to be solved. Specifically, the problem was combining the basic elements of

an add-on for the HiGen MSR to constitute a vision add-on. This vision add-on would

use a camera to detect an object and identify its location within an image frame,

following which it could track it using its on-board actuation. The add-on would be

attached to the robot through a standardised connection method, through which it

would be able to interface with the robot and hence communicate with the rest of the

system.

3.1.1. System Definition

The system being developed is the robot add-on and its subcomponents. The add-on is

a component designed to interface with the robot platform currently being designed at

the University of Sheffield. The scope of the system is the individual add-on and its

subcomponents. The system is part of a larger system comprising the robot/platform](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-39-2048.jpg)

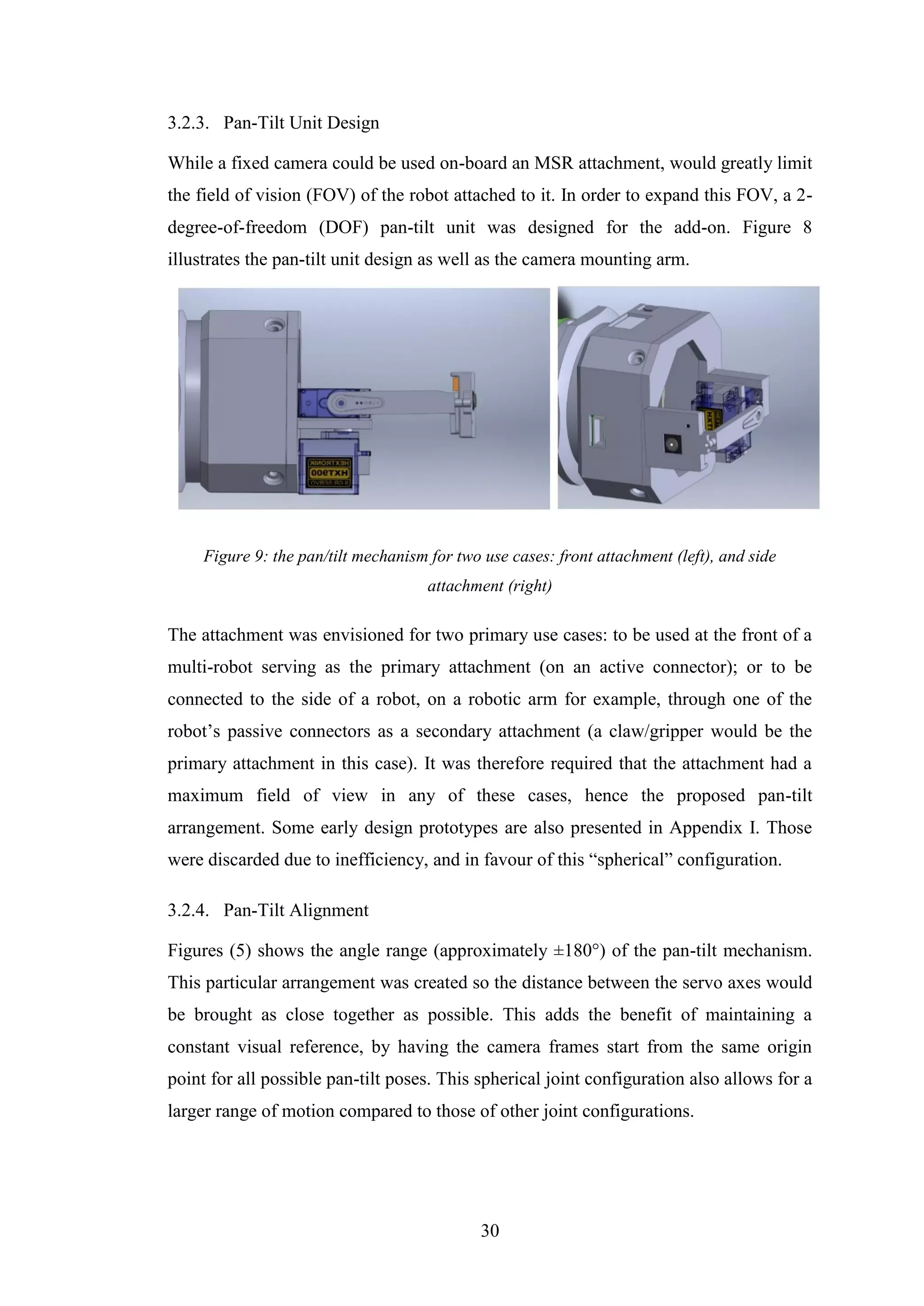

![31

Figure 10: pan/tilt motion arcs, showing a range of approximately ±180°

3.2.4.1. Pan-Tilt Mechanism Actuation

Most pan-tilt actuation mechanisms use standard servo motors. Servo motors are

small, geared motors usually limited to ±180° of rotation, although there are many

designs that allow for continuous rotation. The servos selected for the pan-tilt

mechanism were Hextronik HXT900 9 gram servos, a common size for use on small

robots such as the HiGen module.

3.3. The Single-Board Computer

Following the initial prototyping stage, further in-depth research revealed it would be

much simpler to acquire images or video from a single-board computer (SBC) device

featuring Wi-Fi communication. Several different SBC’s have been compared to

identify which would be suitable for use on-board the add-on. Of these SBC’S, the

Raspberry Pi was deemed the most viable option for the intended use case. Figure 5

shows the four SBC’s that have been compared. Appendix A presents a table

comparing these four devices.

Figure 11: four different single-board computers; Raspberry Pi 2 (left, back); ODroid C1

(right, back); HummingBoard (left, front); MIPS Creator Ci20 (right, front). Reproduced

from [30]](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-46-2048.jpg)

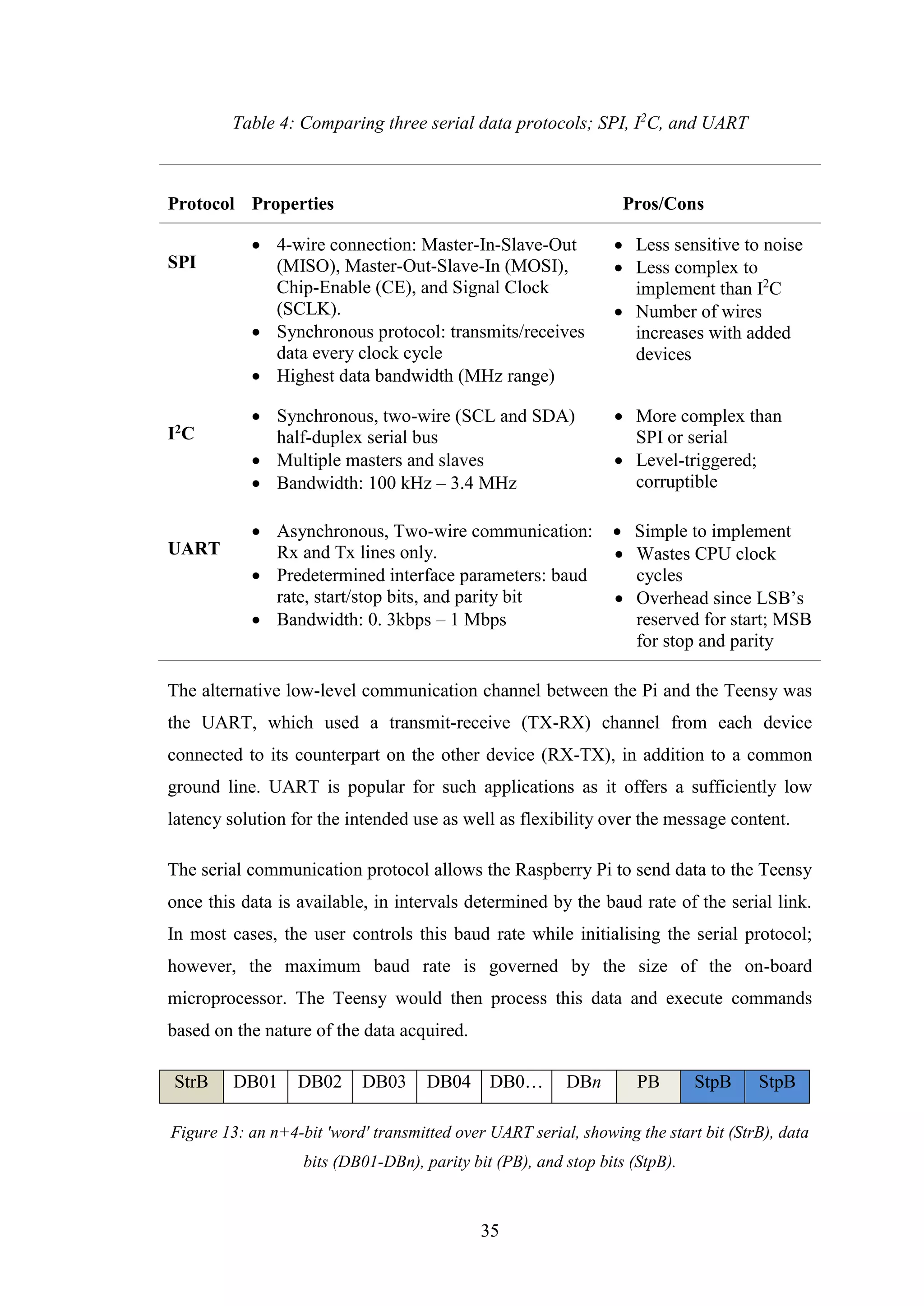

![33

Another added benefit would be exploiting the potential of cloud computing. SBC’s

are designed to interface with the internet, so imbuing the module with direct access

to the Internet of Things (IoT) could have the potential to make the entire MSR

system more powerful and applicable in practice, for live-streaming data and remote

operation. This will be reviewed in more depth in Chapter 6.

3.4.2. The Raspberry Pi Camera

The Raspberry Pi Camera presented itself as the primary candidate for the on-board

camera implementation, as it was readily supported by the Pi in terms of hardware as

well as software interfacing. The powerful, 5 MegaPixel camera unit features an

OmniVision OV5647 camera sensor with a resolution of 2592 x 1944 pixels. The

chosen version of the camera, the Pi NoIR (no IR) has no IR filtering. This type of

camera is commonly used in low-light conditions alongside IR emitters, making it

suitable for poorly lit environments such as caves, inside collapsed buildings, or

inside pipes. Figure 12 shows the Pi NoIR camera.

3.4.3. The Teensy Microcontroller

The HiGen module uses a specialised microcontroller as its “brain”. This device, the

Teensy 3.2 Low Cost (LC) microcontroller, shown in figure 12 (centre), interfaces

with the CC which, in turn, routes the signals to/from the connector board circuit. The

reader is referred to section 2.5.2 for the functions of the CC and connector board).

The Teensy, featuring a 96 MHz Atmel AVR microprocessor and support for various

communication platforms (SPI, UART and I2

C), and a small form factor (35.56 mm x

17.78 mm) render it ideal for embedded applications.

Figure 12: (left) Raspberry Pi NoIR Camera. Retrieved from [31]; (centre) Teensy 3.2 LC

(Low Cost). Retrieved from [32]; (right): Raspberry Pi Model A+. Retrieved from [33]](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-48-2048.jpg)

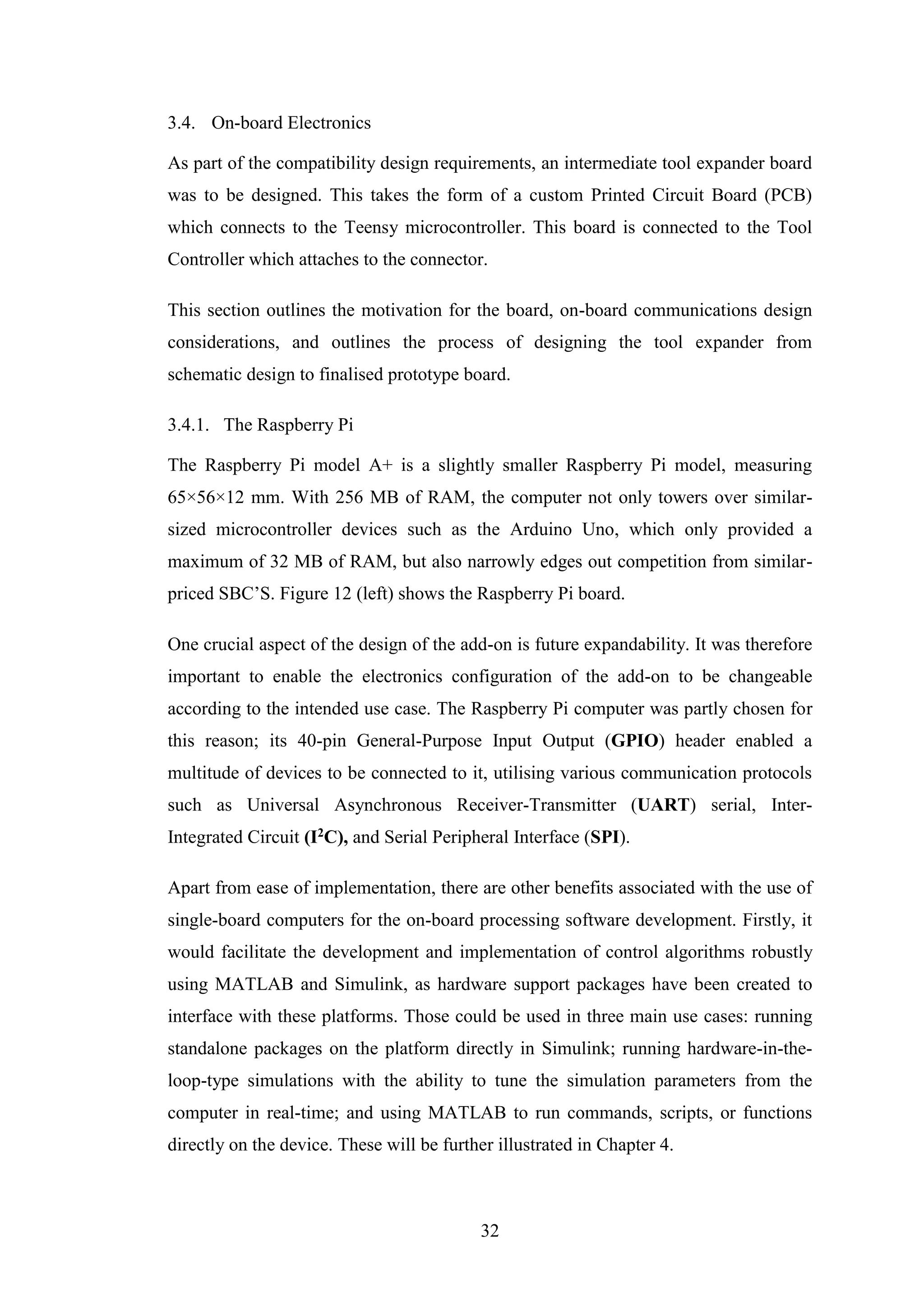

![34

Since the Wi-Fi adapter occupied the board’s only USB port and the Pi’s micro-USB

port was reserved for power and the infeasibility of connecting more peripherals to

the Pi via a powered USB hub, the GPIO provided the alternative low-bandwidth

communication method required to interface with other electronics. It was therefore

important to implement the on-board electronics with this in mind, to help make the

board as expandable as possible.

3.4.4. Low-Level Communication Management

In order to allow more efficient high-level computation on board the Pi for tasks such

as real-time image processing and video streaming over Wi-Fi, it was important to

implement a solution that delegated low-level networking tasks to another device. For

this reason, an intermediate Printed Circuit Board (PCB) was designated as a

communication ‘middleman’ that regulated low-level peripheral control. In addition,

this microcontroller has in-built support for adding Controller Area Network (CAN)

bus communication. The CAN bus is used to enable the robots to exchange low-level

messages about each other’s status and orientation, giving the robots useful

knowledge of the other robots. From within the Pi, low-level control over peripheral

devices is well established, using a selection of open-source, third-party libraries such

as wiringPi [34] for accessing GPIO pins. These libraries, built in a similar fashion to

Arduino libraries, support standard communication protocols such as UART serial,

SPI, and I2

C communication. A summary table of the various communication

protocols compatible with both devices is shown in table 3.

Initially, SPI, the most advantageous protocol, was chosen as the method of

communication between the Pi and the Teensy. However, practical implementation of

this protocol proved too challenging as neither device natively supported running in

SLAVE mode. Several attempts have been made to compile programs including a

third-party library that supported SPI SLAVE mode [teensy-master-slave], but the

programs refused to compile and flagged up numerous errors. Therefore, the use of

SPI was foregone.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-49-2048.jpg)

![43

Chapter 4 - Software Design

This chapter details the various software development activities undertaken within

this project, including low-level hardware code written to interface the Pi and the Tool

Expander, concept testing using MATLAB to verify connectivity capabilities, and

network-level code to communicate between different elements of the add-on: the

add-ons, the robots, the workstation, and the various communication buses. In

addition, some code is demonstrated for some basic task execution, such as simple

face and object detection. Throughout this chapter, line numbers shall be used as

follows to reference their files in Appendixes: e.g. (l. 1-10) marks lines 1 through 10.

4.1. Operating System

Having selected the Pi as the SBC, it was required to select a software environment to

use on-board the computer. Since the Raspberry Pi was capable of running various

operating systems, as presented in Chapter 3, there were several options to choose

from. However, during research it was discovered that MATLAB had released a

hardware support package for Raspberry Pi. Using MATLAB and Simulink greatly

simplified image acquisition, source code development, and implementation on

hardware. It also meant that entire control strategies could be developed and modified

more easily, and powerful tools within Simulink easily exploited to program the add-

on behaviour. This will be further addressed later in the chapter.

Not only was it more convenient to use MATLAB for these purposes, but it also

meant it would be unnecessary to configure large and computationally taxing image

processing code on the Pi, such as the Open Computer Vision library (OpenCV) [35].

According to this tutorial [36], the library would take an excess of 15 hours to install

on the B+ version of the Pi, rendering it much too unwieldy for the less capable A+.

The support package required a specific OS to be installed onto the SD card on-board

the Pi. The OS installed was Raspbian Wheezy, a variant of Linux Debian. The full

version of the OS was installed, although for most cases the add-on would be used in

headless mode, so the default boot option was set accordingly. Using this](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-58-2048.jpg)

![46

1

2

3

4

5

6

7

8

network={

ssid="guest"

psk="shefconfkey"

proto=RSN

key_mgmt=WPA-PSK

pairwise=CCMP

auth_alg=OPEN

}

Figure 20: the supplicant configuration file

4.3. Concept Testing and High-Level MATLAB Connectivity

This section outlines the code developed in MATLAB for interfacing the Pi and the

devices connected to it. This MATLAB code has mainly been used to test out certain

hardware features. In addition to connectivity code, a simple object detection script

was developed to execute on-board the module, to test its processing capabilities.

4.3.1. Pi MATLAB Initialisation

Figure 14 demonstrates the process of interfacing with the Pi through the MATLAB

command prompt. The function raspi initialises a Raspberry Pi board object given

three arguments: its IP address (ip), the username (usr), and password (pswd).

6. ip = '192.168.27.167';

7. usr = 'pi';

8. pswd = 'raspberry'

9. mypi = raspi(ip, usr, pswd)

mypi =

Raspi with Properties:

DeviceAddress: 'mo-pi'

Port: 192.168.27.167

BoardName: 'Raspberry Pi Model A+'

AvailableLEDs: {'led0'}

AvailableDigitalPins: [4 7 8 9 10 11 14 15 17 18 22 23 24 25 27 30 31]

AvailableSPIChannels: {}

AvailableI2CBuses: {'i2c-0' 'i2c-1'}

I2CBusSpeed: 100000

Figure 21 showing the basic initialisation function for a Raspberry Pi board](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-61-2048.jpg)

![47

The object declaration returns a set of properties for the Pi: the device address, Pi

model, the available SPI channels, available I2

C buses and their speed, and available

LED’s. These properties are shown in figure 16.

4.3.2. Camera Board Initialisation

A similar procedure has been used to initialise a camera board object. The function

cameraboard was called to set up a camera board, with the target board ID (mypi) and

the camera resolution as its main arguments. Figure 17 shows this command run and

its output. The output shows numerous parameters that could be used to control

various picture settings, such as brightness, exposure, auto-white balance (AWB),

effects, as well as options for video recording.

10. res = '640x480';

11. mycam = cameraboard(mypi, 'Resolution', '1280x720')

mycam =

Cameraboard with Properties:

Name: Camera Board

Resolution: '640x480' (View available resolutions)

Quality: 10 (1 to 100)

Rotation: 0 (0, 90, 180 or 270)

HorizontalFlip: 0

VerticalFlip: 0

FrameRate: 30 (2 to 30)

Recording: 0

Picture Settings

Brightness: 50 (0 to 100)

Contrast: 0 (-100 to 100)

Saturation: 0 (-100 to 100)

Sharpness: 0 (-100 to 100)

Exposure and AWB

ExposureMode: 'auto' (View available exposure modes)

ExposureCompensation: 0 (-10 to 10)

AWBMode: 'auto' (View available AWB modes)

MeteringMode: 'average' (View available metering modes)

Effects

ImageEffect: 'none' (View available image effects)

VideoStabilization: 'off'

ROI: [0.00 0.00 1.00 1.00] (0.0 to 1.0 [top, left, width, height])

Figure 22 showing the cameraboard initialisation command using the board name

and resolution arguments (top) and the command line output (bottom)](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-62-2048.jpg)

![49

1. for i = 1: 50

2. [img, bw, xm, ym] = trackball(snapshot(cam), 40);

3. figure(2);

4. subplot(211);

5. imagesc(img);

6. subplot(212);

7. imagesc(bw);

8. drawnow;

9. pause(0.150)

10.end

Figure 24: sample code that uses the trackball algorithm to track the position of the green

object

4.4. Tool Expander Programming (The Teensy)

This section outlines the development of low-level code to interface the Teensy with

the Pi and the other board peripherals. As discussed in the previous chapter, the tool

expander board provided a serial communication link between the Pi and the Teensy.

This was used for two-way data streaming between the two devices; the Pi would

upstream messages to the motors, whereas the Teensy would transmit any relevant

status information received from the CAN bus.

Using the serial device support for Raspberry Pi, a serial device (the Teensy

controller) could be initialised as follows (figure 20).

1. teensy = serialdev(mypi, 'dev/ttyAMAO', 115200)

teensy =

Serial Device with Properties:

DeviceAddress: 'mo-pi'

Port: 192.168.27.167

BoardName: 'Raspberry Pi Model A+'

AvailableLEDs: {'led0'}

AvailableDigitalPins: [4 7 8 9 10 11 14 15 17 18 22 23 24 25 27 30 31]

AvailableSPIChannels: {}

AvailableI2CBuses: {'i2c-0' 'i2c-1'}

I2CBusSpeed: 100000

Figure 25: serial device initialisation command; input arguments: host device name

(Raspberry Pi), serial port address, and baud rate](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-64-2048.jpg)

![50

4.4.1. Serial Communication Using MiniCom

Serial communication is well supported within the Raspberry Pi knowledge base,

especially with the use of hardware interface libraries such as [34]. However, for the

purpose of this project the library was not used within standalone C++ programs. To

test serial communication, the Teensy was programmed to write out incrementing

values and the same values were read from the serial port on the Pi. A simple serial

communication tool, called MiniCom, was installed and used to read the serial output

from the Teensy, and the Serial Console of the Arduino IDE was used to read out the

data written to the Teensy serial port. To use MiniCom, the command was input to the

SSH command line, and a screenshot of the data exchange is shown in Figure 24 (top

and bottom respectively).

1. minicom -b -o 9600 -D /dev/ttyAMA0

Figure 26: MiniCom used to input values to the serial port via SSH (left) and the Arduino

serial monitor echoing the data read (right).

The command allows the user to specify the baud rate of the serial interface initialised

(9600 in this case). The port action (i.e. open) is specified by the -o tag, whereas the

device address is specified using the -D tag. The Teensy was connected to serial port

(/dev/ttyAMA0), corresponding to the serial port on the Raspberry Pi.

4.4.2. Pan-Tilt from Keyboard

Having verified the serial functionality with MiniCom, it was desired to test the PWM

functionality of the Teensy, to verify its ability to send pan-tilt motor commands to

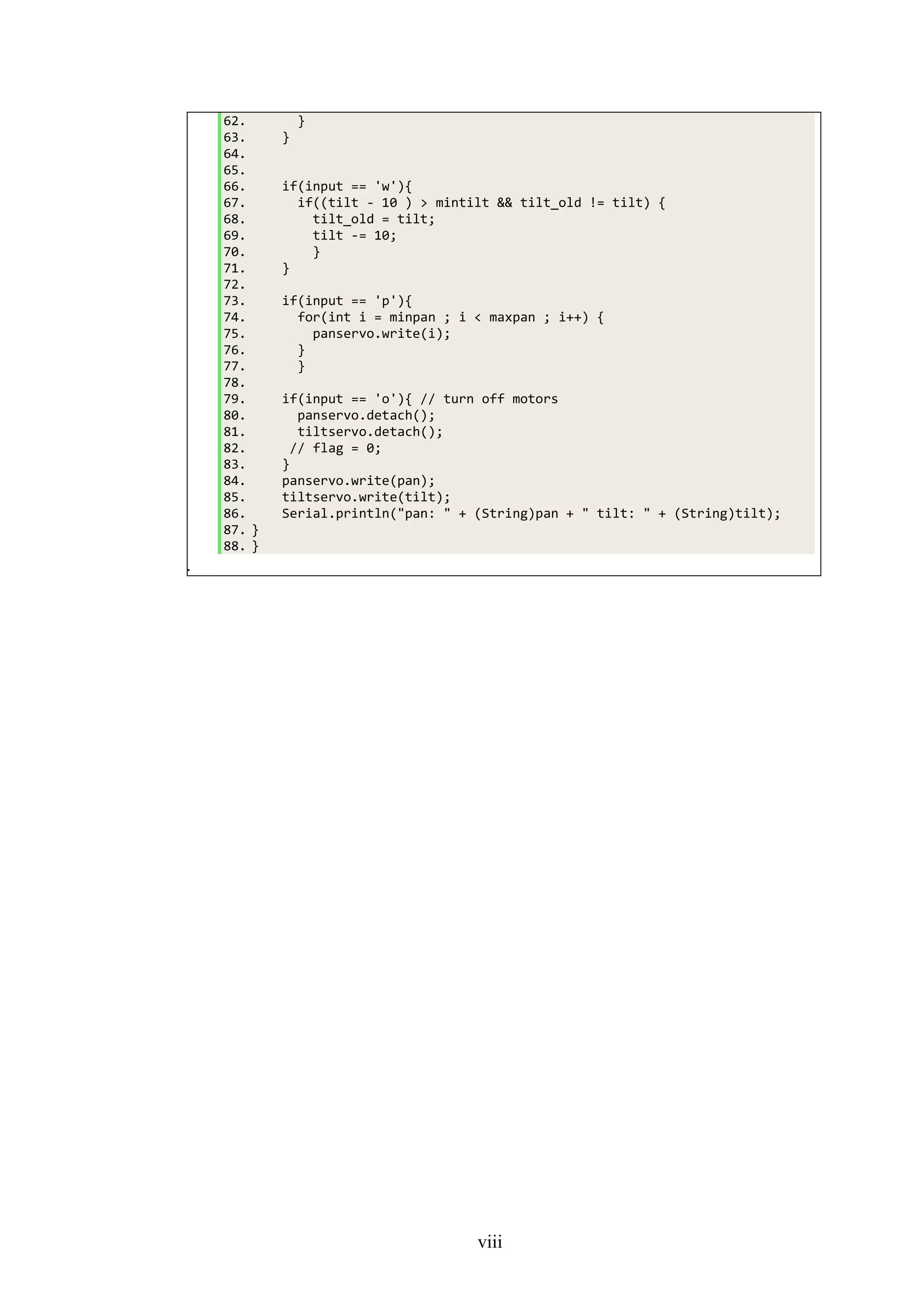

the pan-tilt servos. One of the first examples used was a basic program which coded

the WASD pad (‘w’, ‘a’, ‘s’ and ‘d’ keyboard keys) to servo turning commands. An](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-65-2048.jpg)

![53

The MATLAB program calculated the difference between the current x-and y-

position of the object centre and the previous value. A bounding box was

subsequently drawn around the image centroid (the red dot). If the new value lay

outside the bounding box, the program would command the motor to actuate in the

direction opposite to the difference, to re-focus within the box. For example, if the

difference between the current and previous points were greater than 20 pixels to the

left, a command would be sent to the motor to move to the left so the point was back

within the box. A sample screen output is shown in figure 29Error! Reference

source not found.. Appendix [G] details the sample code used for this experiment.

Figure 29: (left) object centre and bounding box surrounding object; (right) thresholded

version of the image](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-68-2048.jpg)

![54

Chapter 5 - Experimentation and Results

Once the main software features of the system were designated, it was required to

ensure they could be integrated together. This chapter introduces a model developed

for tracking an object with the pan-tilt mechanism. A brief analysis of this model is

also introduced. Finally, this chapter introduces the foundations of designing the

integration and testing code. The primary chosen development environment for this

code was Simulink, where simple blocks were combined to produce a basic controller

for the add-on.

5.1. The Target Tracking Problem: Approach

Target tracking in Computer Vision (CV) takes many forms. The Visual Servo (VS)

problem, a specific subset of target tracking problems, could be modelled using three

main hardware configurations: Eye-in-hand VS occurs when the camera is attached to

a 6 DOF robotic manipulator; eye-to-hand VS is when a camera, or multiple cameras,

are used to observe the robot or manipulator; and pan-tilt VS, where the camera is

controlled using a pan-tilt servo configuration, i.e. 2 DOF. For the case of pan-tilt

tracking, insights derived from eye-in-hand and pan-tilt VS approaches were studied.

5.2. The Target Tracking Problem: Framework

Computer vision makes extensive use of geometric transformations to map real-world

coordinates to equivalent points within an image plane. These coordinates could then

be used to, for example, estimate the pose of the object, or the camera with respect to

the object, or even the distance away from the object [37]. Several camera

configurations have been used for the purpose of object, as well as motion, tracking,

namely using multiple cameras simultaneously or using a system of stereo cameras to

triangulate objects. It was desired to explore using such methods to model pan-tilt

tracking. Specifically, given a position of a point in the real-world, the objective was

to find pan and tilt angles that would re-centre the view on that target point. A model

proposed in [38] introduces a mathematical set of procedures, or “forward pipeline”,

to map a 3D real-world point onto a corresponding 2D image plane, as well as an

“inverse” pipeline to obtain the reverse transformation.](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-69-2048.jpg)

![55

The model introduces a method of describing the position of a point T with

coordinates (xt, yt, zt) in real-world coordinates projected onto the plane of the image,

forming the point P (xp, yp, zp). The image plane is defined with a centre D (xp, yp, zp),

and the vector 𝑂𝐷⃗⃗⃗⃗⃗⃗ is the direction vector of the virtual camera view (where O is the

origin). The pan and tilt angles, 𝜑 𝑑 and 𝜃 𝑑, determine the direction of 𝑂𝐷⃗⃗⃗⃗⃗⃗ in world

coordinates. In most cases, the roll angle (the rotation about the y-axis) is ignored, as

the corresponding DOF could be replaced by a software algorithm that rotates the

corresponding image. The formulation of the model is represented in Figure 30Figure

30.

To re-centre the camera view on the target point P on the image plane, the view must

rotate by the pan and tilt angles that correspond to the distances between the point P

and the centre D. These rotations are executed by the pan-tilt motors.

Figure 30: the point T (left diagram) corresponds to an equivalent point on an image plane

EFGH (the top of a frustum). The equivalent real-world plane in which T lies maps out the

base of a frustum, E’F’G’H (right). The frustum EFGH-E’F’G’H defines the projection

volume. Reprinted from [38].

The angles 𝜃 𝑑 and 𝜑 𝑑 pertaining to the direction vector 𝑂𝐷⃗⃗⃗⃗⃗⃗ are simply calculated as

the ratio between the depth zd, and the vector norm (for the tilt angle), and the inverse

of the tangent of yd and xd.

A set of geometrical parameters could be used to describe the frustum and thus

required to define the pan-tilt model; the vertical field-of-view (FOV) α, the vector](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-70-2048.jpg)

![56

𝑂𝐷⃗⃗⃗⃗⃗⃗ , its normal distance (n) from the optic centre O, the aspect ratio, r, of the image

(where r = |EF/FG|), the vector norm of OD (i.e. the distance between O and the top

of the frustum), and the distance between OD and the base of the frustum.

Applying the inverse pipeline of the model developed in [34] yields a model which

relates the point (xp’’,yp’’,zp’’) to the point (x,y,z), by the inverse of the view

transformation matrix Mview. The convert the new centre of the target feature (u, v), to

the corresponding pan and tilt angles through the following trigonometric identities:

𝜃 𝑑 = arccos(

𝑧 𝑑

√𝑥 𝑑

2+𝑦 𝑑

2+𝑧 𝑑

2

) ; 𝜑 𝑑 = arctan(

𝑦 𝑑

𝑥 𝑑

)

Equation 2: the pan and tilt angles obtained from the inverse pipeline method described in

[34]

5.3. Target Tracking: Experiments

As mentioned in the previous chapter, one of the reasons for choosing MATLAB as

the primary development environment for the add-on was the presence of built-in

hardware support for the Raspberry Pi. Through the use of the Simulink support

package for the Pi, two different modes of operation could be used: external mode,

where the tuning parameters of the model could be modified in real-time; and

standalone mode, where the model could be complied into source code and embedded

directly onto the Pi.

Before attempting to control the plant developed using the geometric model, it was

desired to verify the model to ensure it would yield principally sound results. A

simple experiment was therefore designed, using the following MATLAB code to

locate the centroids of the object tracked and, following which, plot its changes over

time.

5.3.1. Experimental Outline

Appendix G shows a MATLAB script which applied the calculated pan and tilt

transformations on a set of x- and y- coordinates acquired through the Raspberry Pi

camera, using the pan-tilt model. The function iterated through 500 samples,

calculated the pan-tilt angles, then calculated the difference between the current and

past pan and tilt angles, dφ and dθ. The target object, a green business card, was placed](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-71-2048.jpg)

![59

random number signals and the model, and then again from the model to the feedback

pathway. These delays resemble real-time communication latency and serve to

prevent algebraic loops within the model, brought about from using a feedback loop

to provide new values of pan and tilt to the model.

The control scheme of choice could vary depending on the required performance

output. A basic methodology to develop such a control scheme, based on error

tracking, is outlined in the following section. Owing to time constraints, it was not

possible to implement and test a control strategy to verify the model.

5.4. Target Tracking: Controller Design

The tracking problem, in its simplest form, could be viewed as attempting to minimise

a time-varying error term,

𝑒(𝑡) = 𝑠[𝑚(𝑡), 𝑎] − 𝑠∗

,

Equation 3: the visual servo (VS) problem as an error minimisation of the target

feature w.r.t. the current camera target. Reprinted from [39]

where e(t) denotes the error, s denotes the current observed feature in terms of its

pixel coordinates m(t) and additional knowledge extracted from the frame (denoted by

a), and s* denotes the desired target feature. The two general techniques that exist,

Image-Based (IBVS) and Position-Based (PBVS), differ mainly in how s is defined.

In IBVS, s is specified as a set of coordinates within the target frame, whereas in

PBVS, s corresponds to a set of 3D parameters estimated from image measurements

[39].

The interaction matrix for a given point is generated from a mapping between the

point in real world coordinates and the camera’s focal length. The parameters within

this matrix are obtained directly from the image or can be measured during the camera

calibration. The interaction matrix is defined as

𝐿 𝒙 = (

−1 𝑍⁄ 0 𝑥 𝑍⁄

0 −1 𝑍⁄ 𝑦 𝑍⁄

𝑥𝑦 −(1 + 𝑥2

) 𝑦

1 + 𝑦2

−𝑥𝑦 −𝑥

) .

Equation 4: the interaction matrix of the point x. Reprinted from [39]](https://image.slidesharecdn.com/ca626474-80ef-4230-a9c1-9d2dbef4c309-160828124550/75/Mohamed-Marei-120126864-Dissertation-Design-and-Construction-of-Hardware-Add-ons-for-a-Modular-Self-Reconfigurable-Robot-System-74-2048.jpg)

![60

In this matrix, X, Y, and Z correspond to the real-world coordinates of a point x,

whereas x and y are projections of these points on the image plane.

The projections x and y are obtained using the following equations:

𝑥 =

𝑋

𝑍

= (𝑢 − 𝑐 𝑢) 𝑓𝛼⁄ ; 𝑦 =

𝑌

𝑍

= (𝑣 − 𝑐 𝑣) 𝑓⁄ .

Equation 5: image coordinates x and y defined in terms of the pixel coordinates (u

and v), the focal length (f), the camera centre (cu and cv), and the pixel ratio α.

Reprinted from [39]

The velocity of the point (x, y) in terms of linear and angular components, is

therefore:

𝑥̇ = −𝑣𝑥/𝑍 + 𝑥𝑣𝑧/𝑍 + 𝑥𝑦𝜔 𝑥 − (1 + 𝑥2

)𝜔 𝑦 + 𝑦𝜔 𝑧 ;

𝑦̇ = −𝑣 𝑦/𝑍 + 𝑦𝑣𝑧/𝑍 + (1 + 𝑦2

)𝜔 𝑥 − 𝑥𝑦𝜔 𝑦 − 𝑥𝜔 𝑧 .

Equation 6: the velocity of x in terms of the linear and angular components of the

target’s motion

The shorthand notation for equation 5 is 𝒙̇ = 𝑳 𝒙 𝑣𝑐, i.e. the same form as equation 2.

In PBVS and IBVS, the value of the depth of the target point must be known, either

through direct measurement or estimation [39]. In the estimation case, Chaumette and

several others propose Kalman filters to obtain estimates of the robot’s trajectory.

However, equivalent methods could be applied to estimate the position of the image

x- and y-coordinates. This would involve describing the states of the system as the x-

and y-coordinates of the point on the target feature (i.e. the object’s centroid), rather

than the coordinates of the moving robot.

5.5. Camera Calibration

To use either model for VS, camera calibration is essential to identify the intrinsic

camera parameters: the focal length, f, the principal point coordinates (cu, cv), the

camera skew α, and the pixel ratio of the camera [37]. MATLAB provides an in-built

tool to calibrate different camera configurations; it could be used with either a stereo