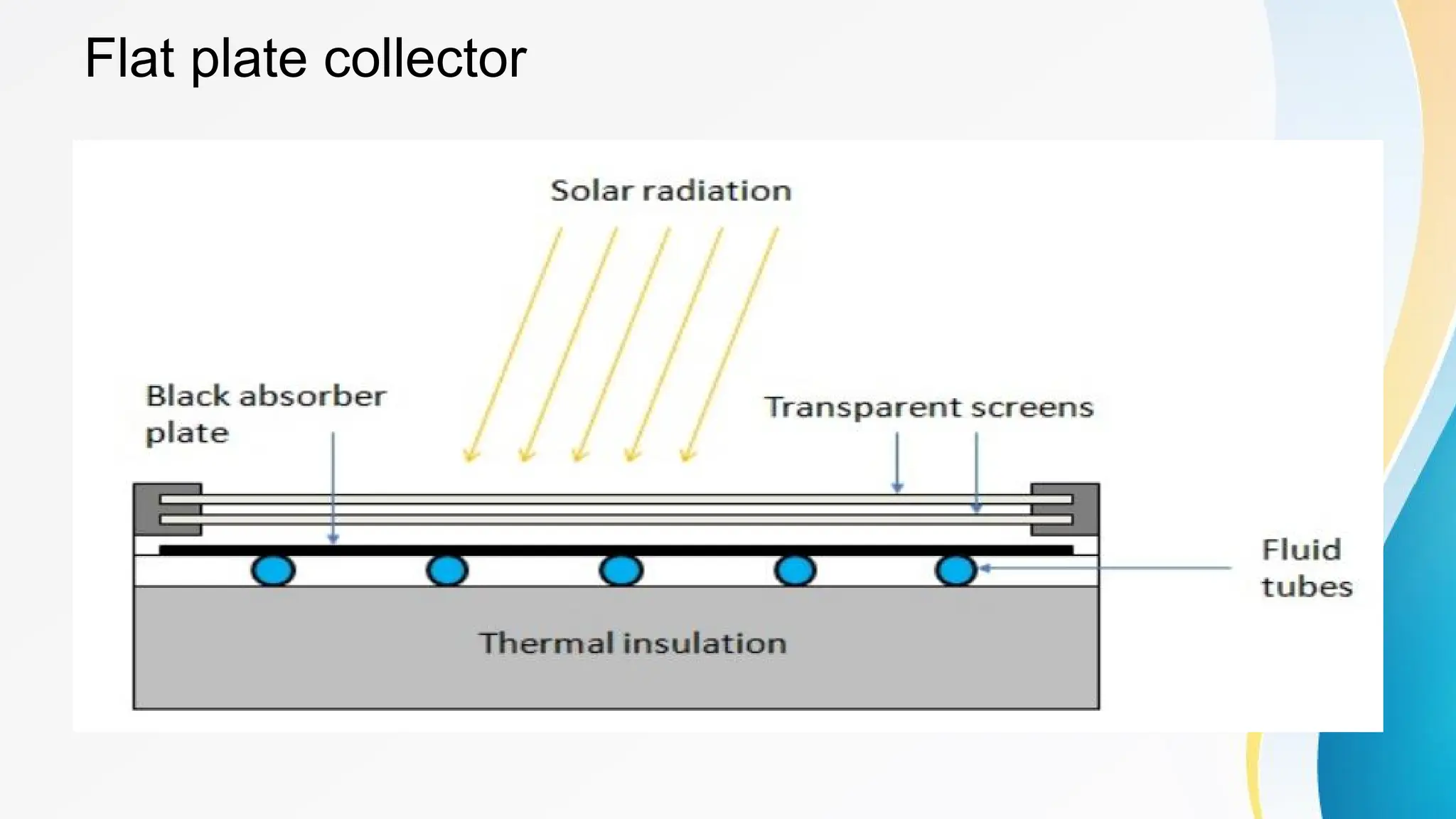

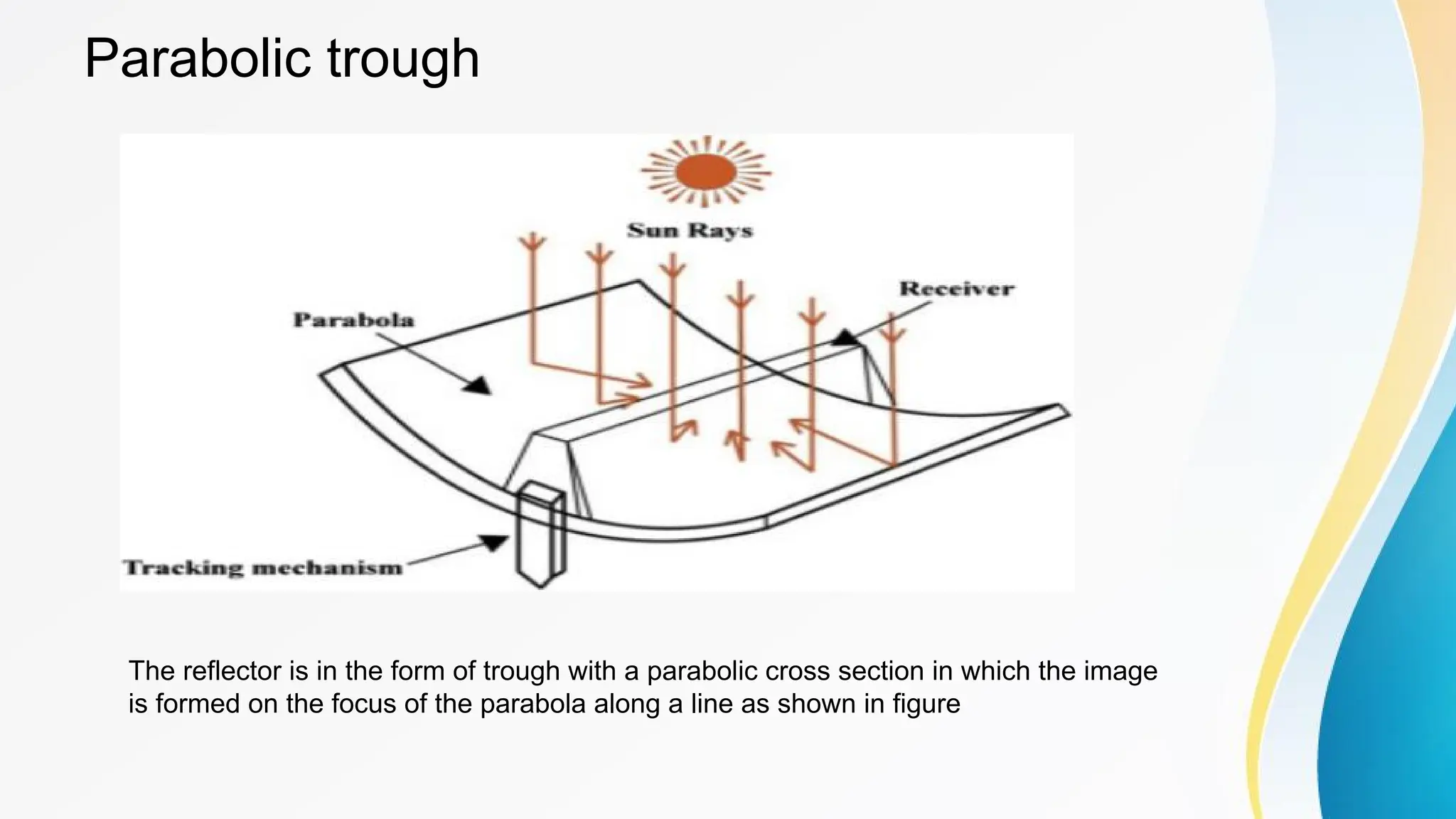

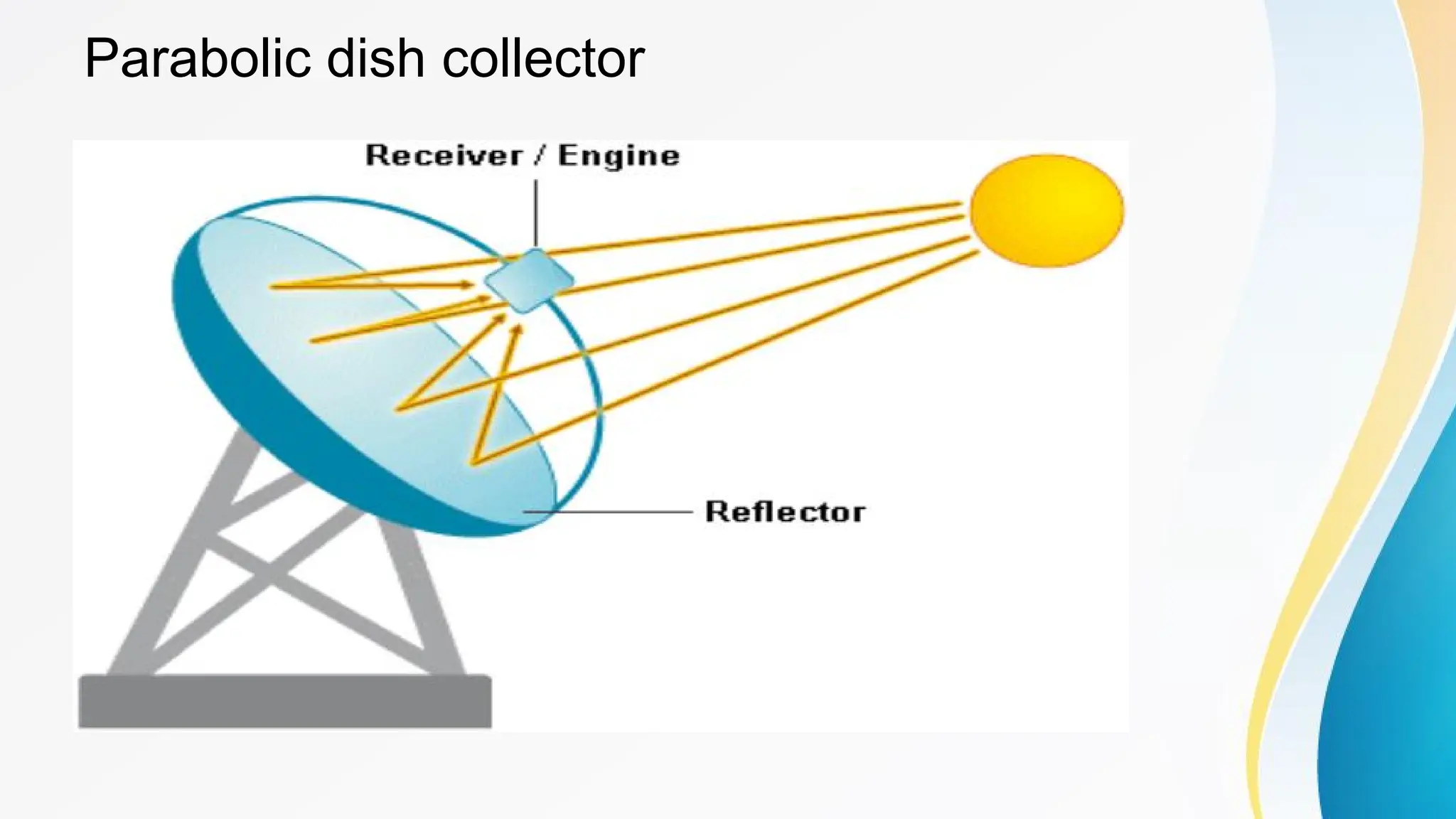

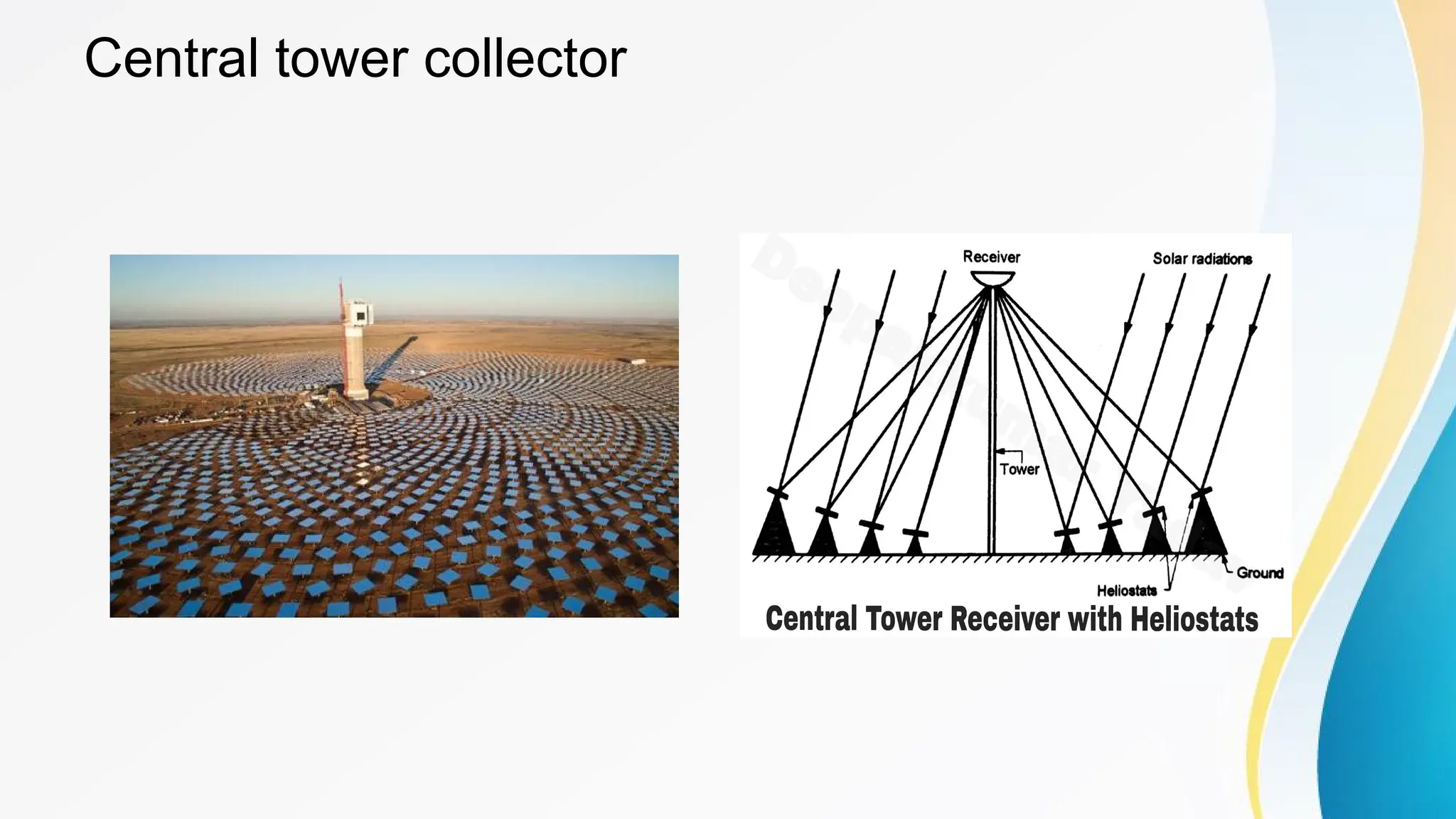

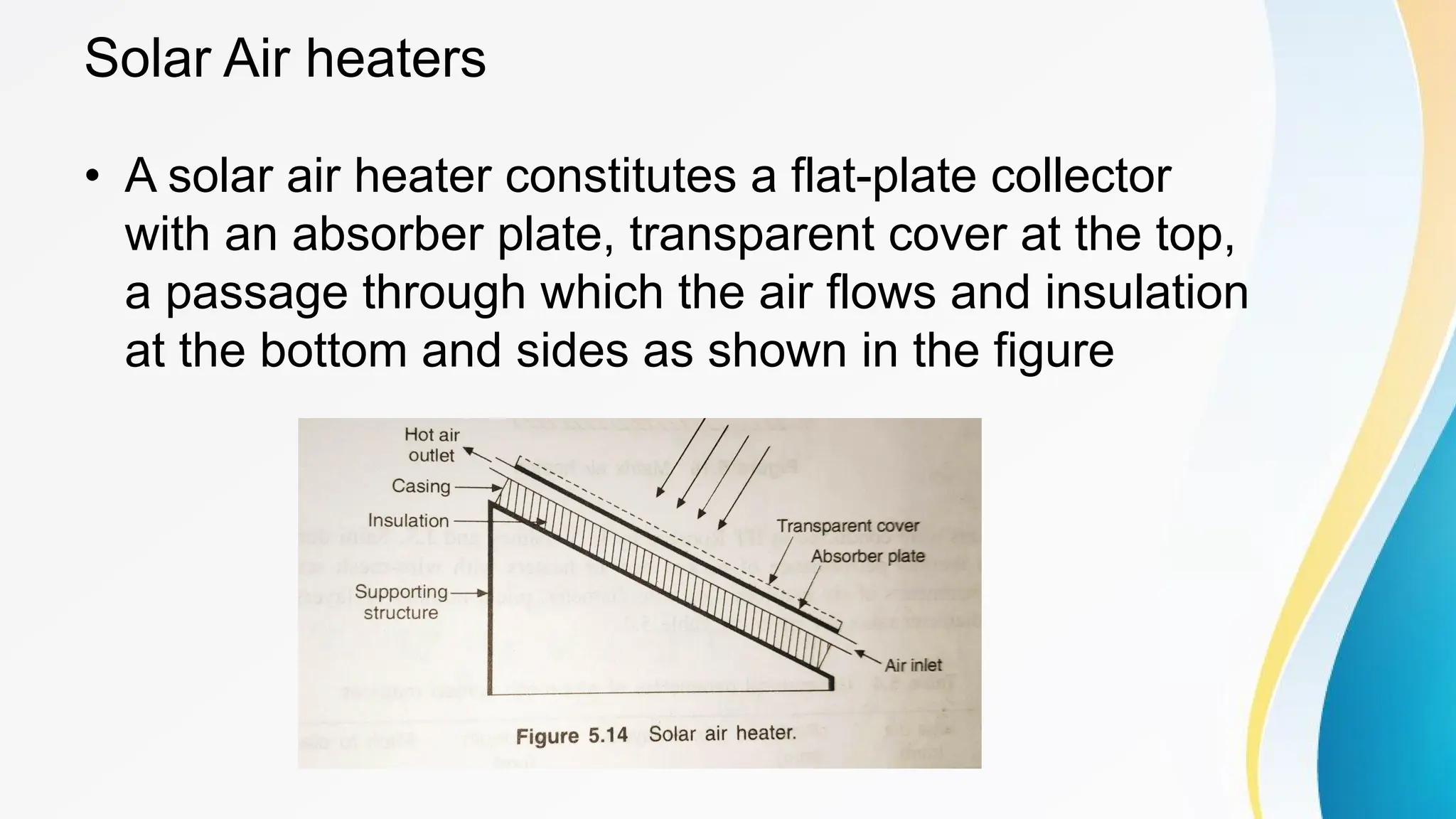

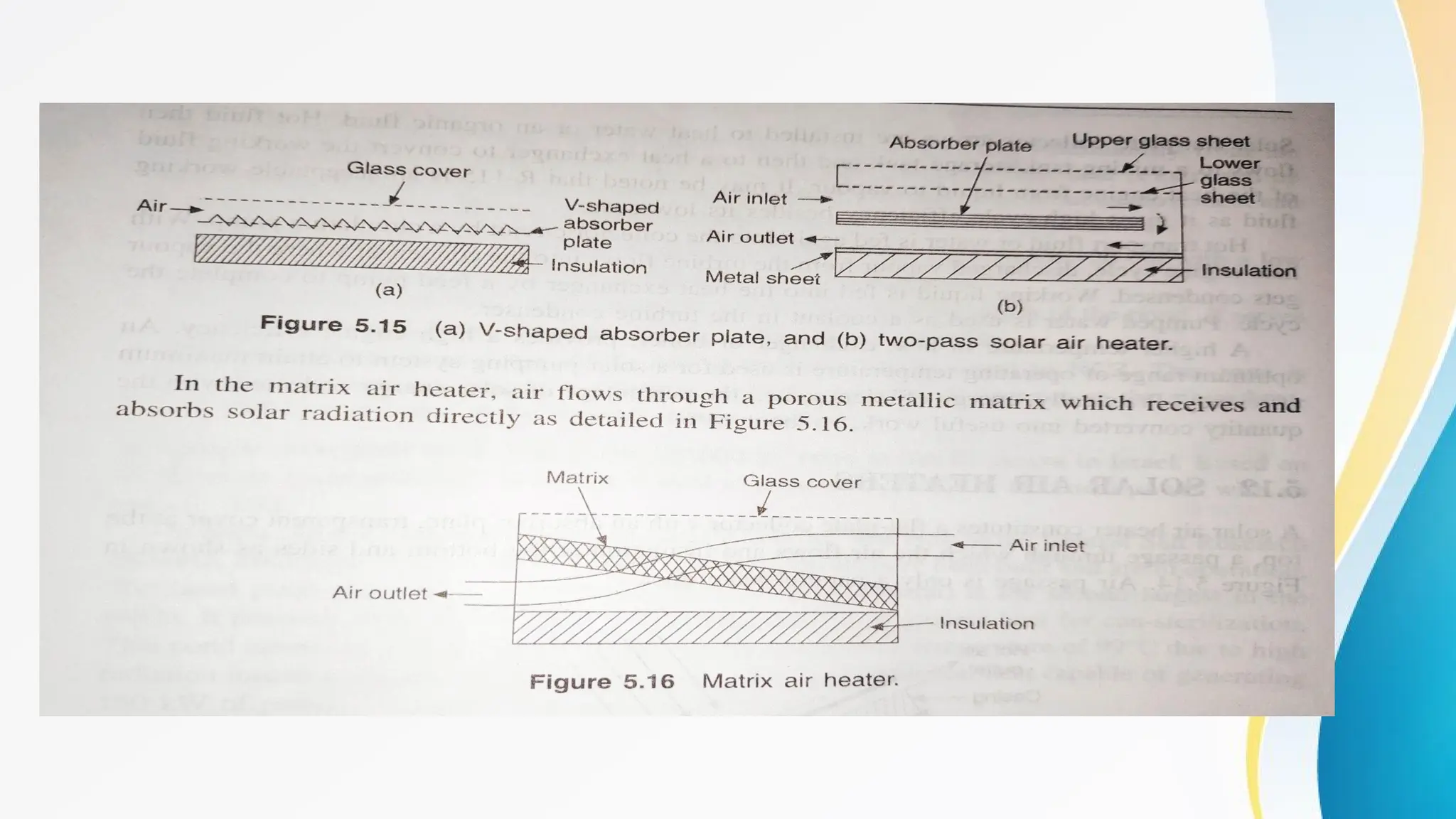

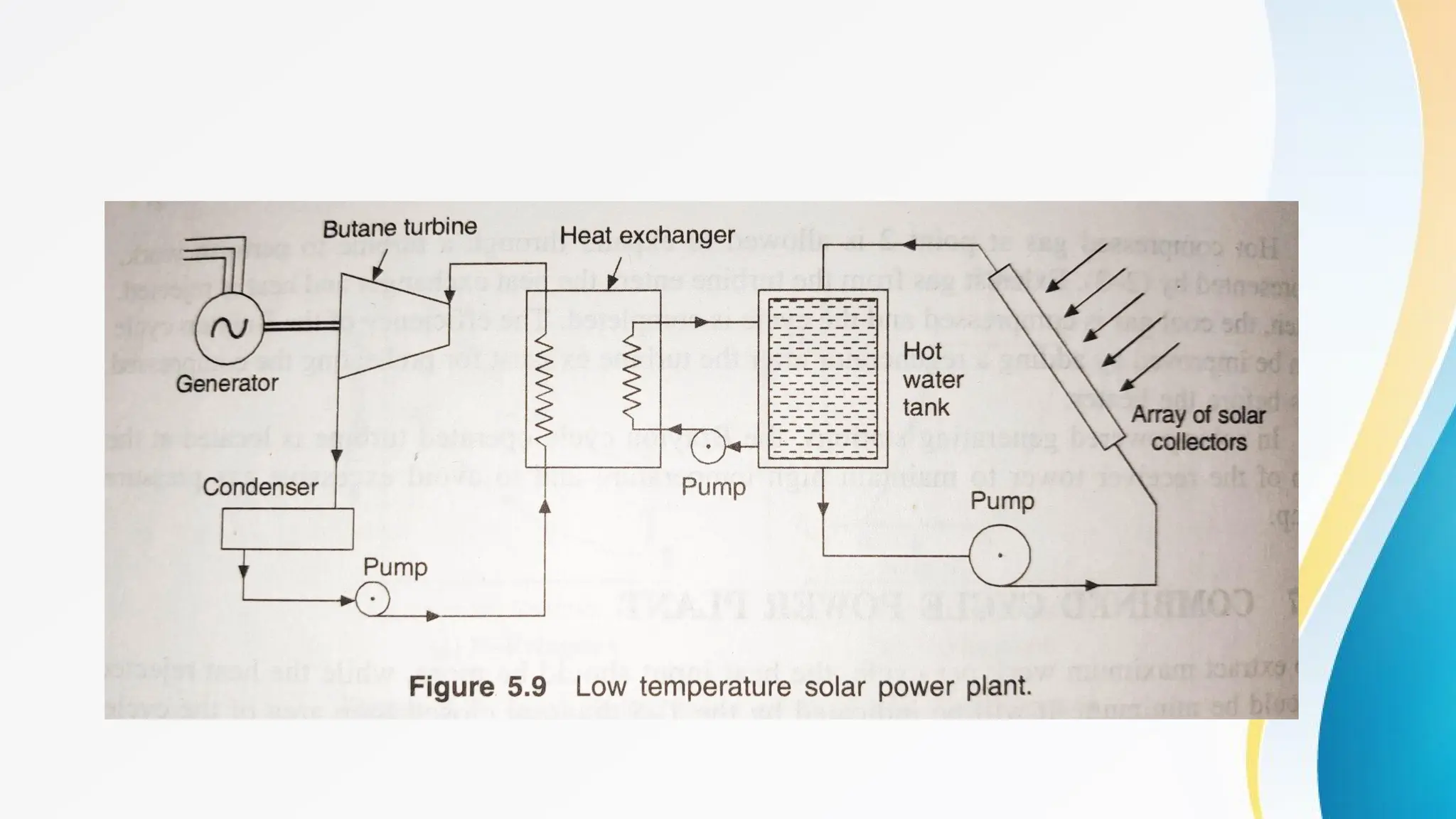

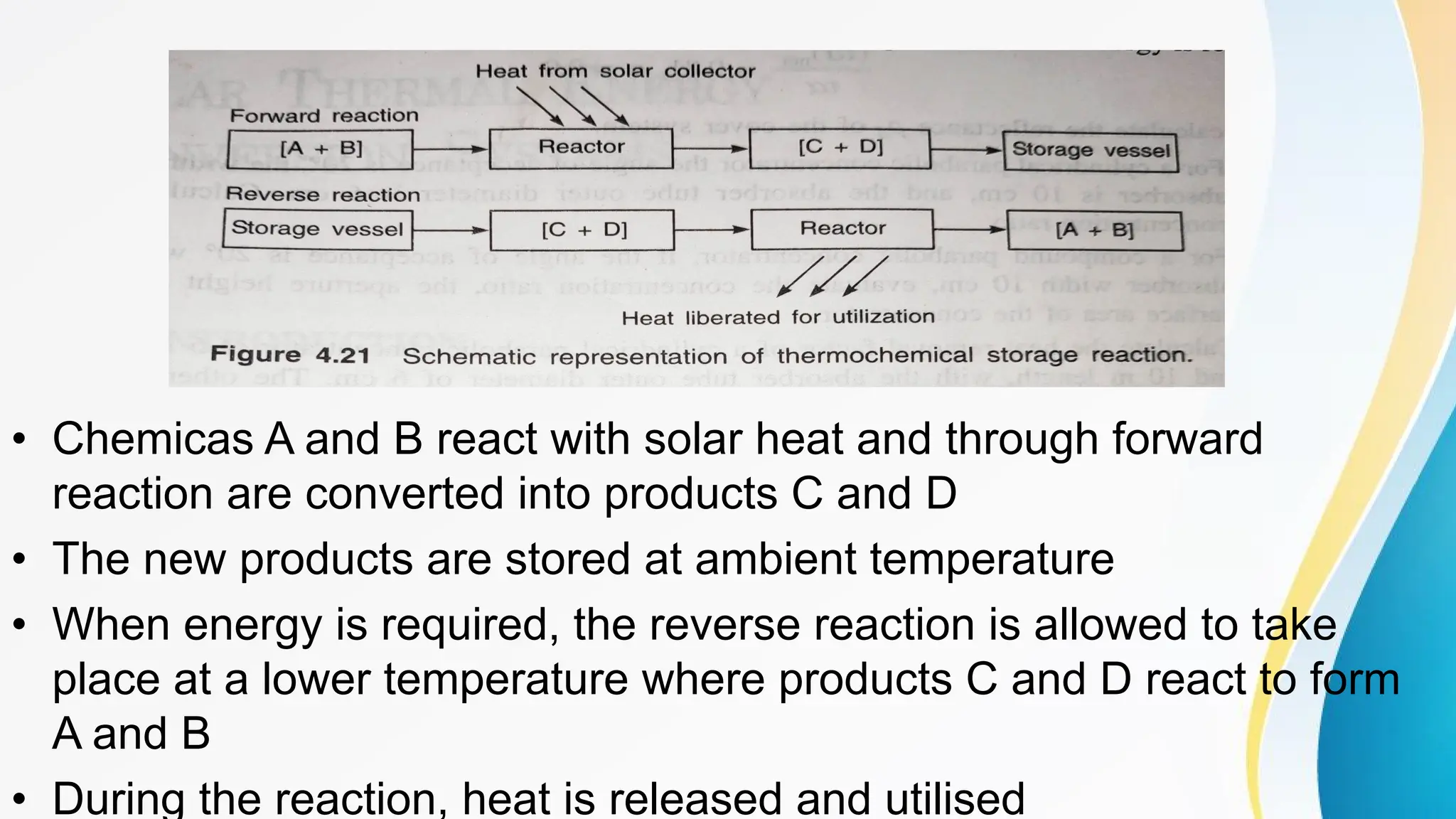

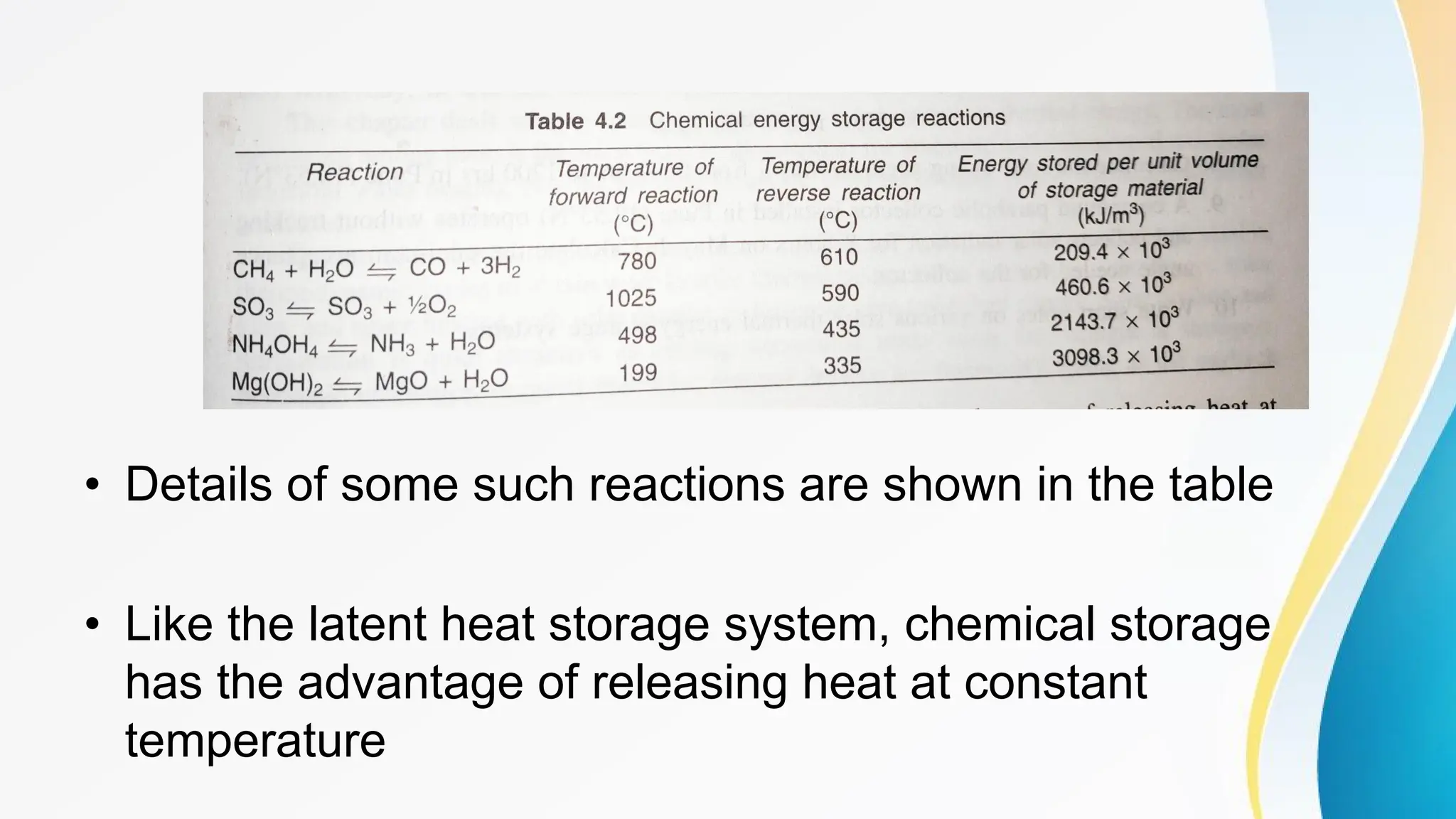

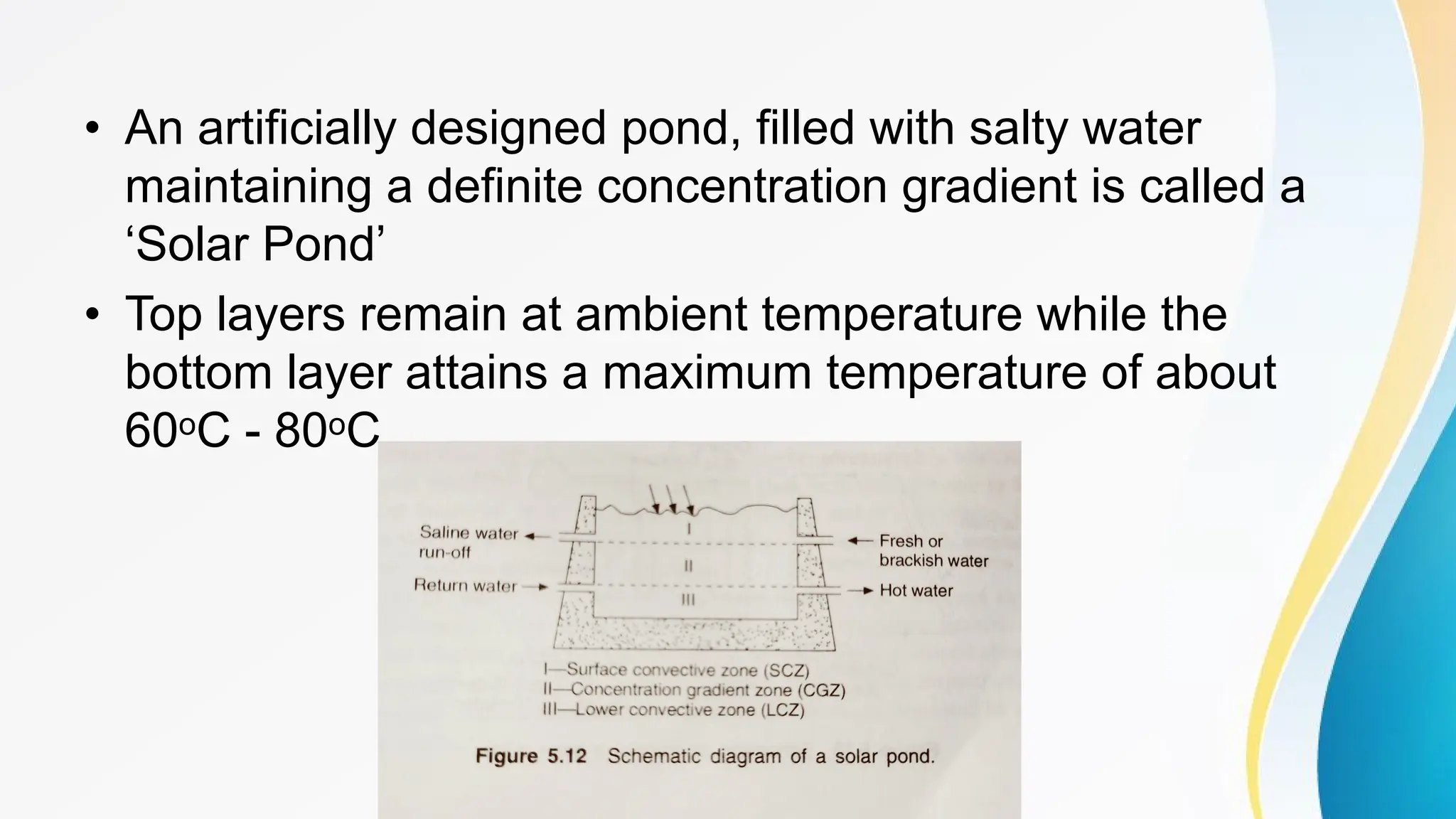

This document discusses various techniques for harnessing solar energy, including solar thermal and photovoltaic methods. It describes different types of solar collectors like flat plate collectors and concentrating collectors. It also discusses solar thermal energy storage methods like sensible heat storage using water or molten salts, latent heat storage using phase change materials, and thermochemical storage using reversible chemical reactions.